Mouldy bran culture medium for enlarged culture of aspergillus niger and culture method

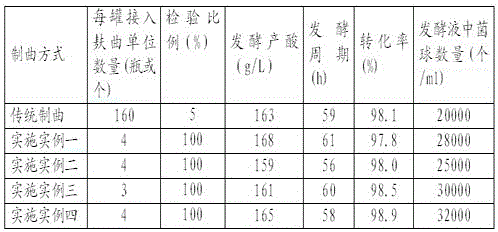

A technology for expanding cultivation and cultivation methods, which is applied to the bran koji culture medium and the field of cultivation of Aspergillus niger species bran koji, which can solve the problems of occasional bacterial contamination, large number of bottles, and difficulty in scheduling, so as to reduce the quantity , Increase the loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The selection of corn cob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: take 800g of corn steep liquor powder and glucose, 120g of ammonium sulfate, mix and dissolve with water, and make up to 6L after dissolution. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0039]Aspergillus niger CICC40021 preserved in China Industrial Microbiology Culture Collection Center (CICC) was used as the strain source. Put 1.9kg of the finished culture medium into a 20L culture container, add 3.2L of water, sterilize at 121°C for 90min, and inoculate after cooling. The culture conditions are as follows: the ventilation rate is 1:0.25 volume: (volume min) in the first three days, the ventilatio...

Embodiment 2

[0043] The selection of corn cob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: take 200g each of corn steep liquor powder and glucose, 30g of ammonium sulfate, and 5L of soybean meal enzymatic hydrolysis filtrate, add water to mix and dissolve, and make up to volume after dissolving 6L. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0044] Put 1.9kg of the finished culture medium into a 20L culture container, add 3.2L of water, sterilize at 121°C for 90min, and inoculate after cooling. The culture conditions are as follows: the ventilation rate is 1:0.25 volume: (volume min) in the first three days, the ventilation rate is 1:0.5 volume: (volume min) in the next seven days, the fir...

Embodiment 3

[0048] The selection of corncob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: take 400g of corn steep liquor powder and glucose, 60g of ammonium sulfate, 2L of soybean meal enzymatic hydrolysis filtrate, add water to mix and dissolve, and make up to volume after dissolving 6L. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0049] Put 3kg of the finished culture medium into a 30L culture container, add 4.8L of water, sterilize at 121°C for 90min, inoculate and culture after cooling. The culture conditions are as follows: the ventilation rate is 1:0.25 volume: (volume min) in the first three days, the ventilation rate is 1:0.5 volume: (volume min) in the next seven days, the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com