Preparation method of wolfberry distilled liquor

A technology for distilled wine and wolfberry, which is applied in the field of preparation of wolfberry distilled wine, can solve problems such as waste of resources, and achieve the effects of reducing waste discharge, improving comprehensive quality, and saving costs and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

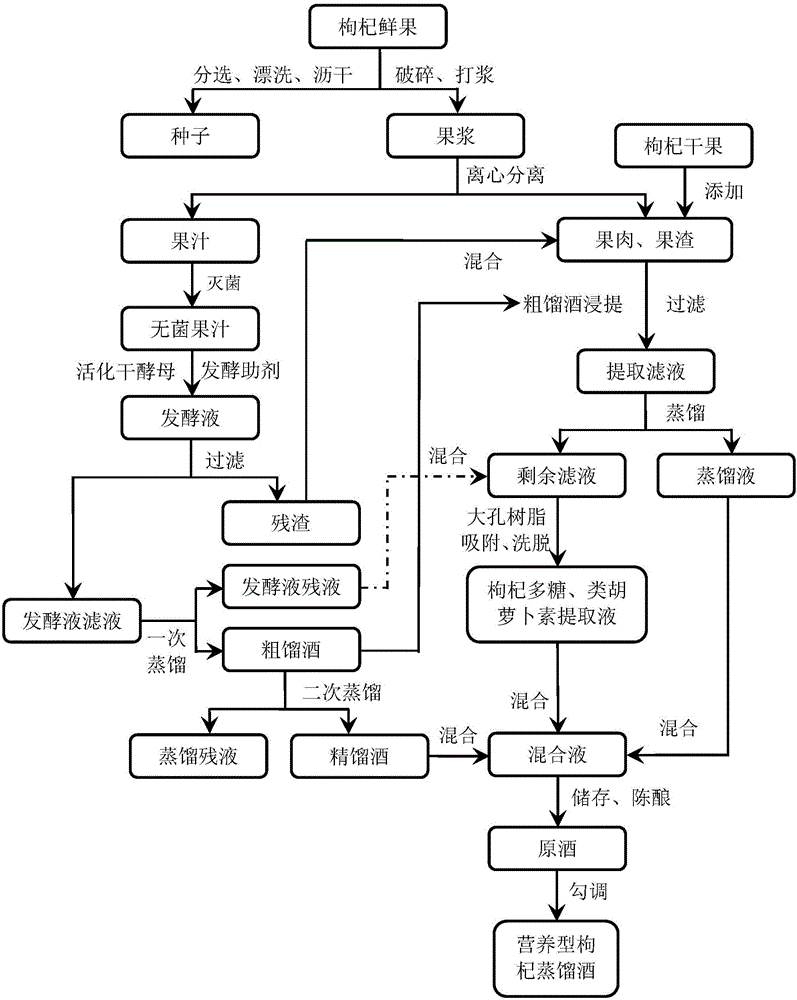

Method used

Image

Examples

Embodiment 1

[0038] (1) Raw material handling:

[0039] Sorting and cleaning: select the fresh goji berry fruit with no mechanical damage, disease and insect spots, mildew and deterioration on the surface, remove disease and insect fruit, fruit stem and other impurities, spray with clean water, rinse and drain;

[0040] Crushing and beating: use the material pump to send the cleaned fresh fruit of wolfberry to the beater for beating, separate the pulp from the seeds of wolfberry, and collect the pulp and seeds separately;

[0041] Separation of fruit juice: the wolfberry juice pulp that has been beaten and deseeded is separated from the pulp and pomace in the pulp by a horizontal centrifuge, and the standby speed is 4000r / min;

[0042] Sterilization: The juice obtained by centrifugation is instantaneously sterilized at high temperature; the conditions for high-temperature instantaneous sterilization are: preheat the clear juice after centrifugation to 50°C, sterilize at 114°C for 6 seconds...

Embodiment 2

[0055] (1) Raw material handling:

[0056] Sorting and cleaning: select the fresh goji berry fruit with no mechanical damage, disease and insect spots, mildew and deterioration on the surface, remove disease and insect fruit, fruit stem and other impurities, spray with clean water, rinse and drain;

[0057] Crushing and beating: use the material pump to send the cleaned fresh fruit of wolfberry to the beater for beating, separate the pulp from the seeds of wolfberry, and collect the pulp and seeds separately;

[0058] Separation of fruit juice: the goji berry juice pulp that has been beaten and deseeded is separated from the pulp and pomace in the pulp by a horizontal centrifuge, and the standby speed is 4500r / min;

[0059] Sterilization: high-temperature instantaneous sterilization of the juice obtained by centrifugation; the conditions for high-temperature instantaneous sterilization are: preheat the clear juice after centrifugation to 50°C, then sterilize at 116°C for 2 sec...

Embodiment 3

[0072] (1) Raw material handling:

[0073] Sorting and cleaning: select the fresh goji berry fruit with no mechanical damage, disease and insect spots, mildew and deterioration on the surface, remove disease and insect fruit, fruit stem and other impurities, spray with clean water, rinse and drain;

[0074] Crushing and beating: use the material pump to send the cleaned fresh fruit of wolfberry to the beater for beating, separate the pulp from the seeds of wolfberry, and collect the pulp and seeds separately;

[0075] Separation of fruit juice: the wolfberry juice pulp that has been beaten and deseeded is separated from the pulp and pomace in the pulp by a horizontal centrifuge, and the standby speed is 4300r / min;

[0076] Sterilization: high-temperature instant sterilization of the juice obtained by centrifugation; the conditions for high-temperature instant sterilization are: preheat the centrifuged clear juice to 50°C, then sterilize at 115°C for 4 seconds, and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com