Preparation method of high-electric-conductivity graphene/natural rubber nano-composite

A nano-composite material, natural rubber technology, applied in the field of preparation of conductive rubber nano-composite materials, can solve the problems of time-consuming, limited industrial application, difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

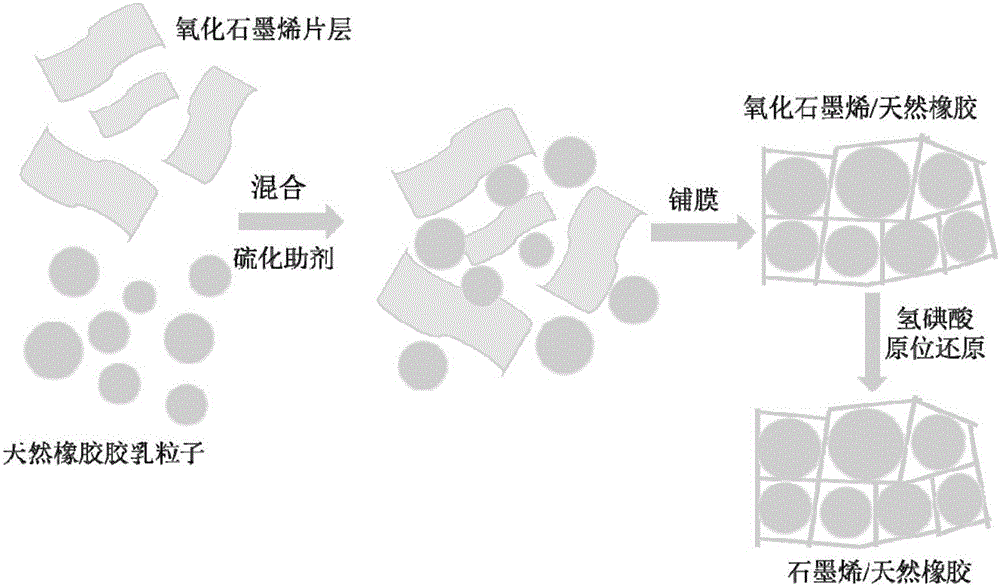

Method used

Image

Examples

Embodiment example 1

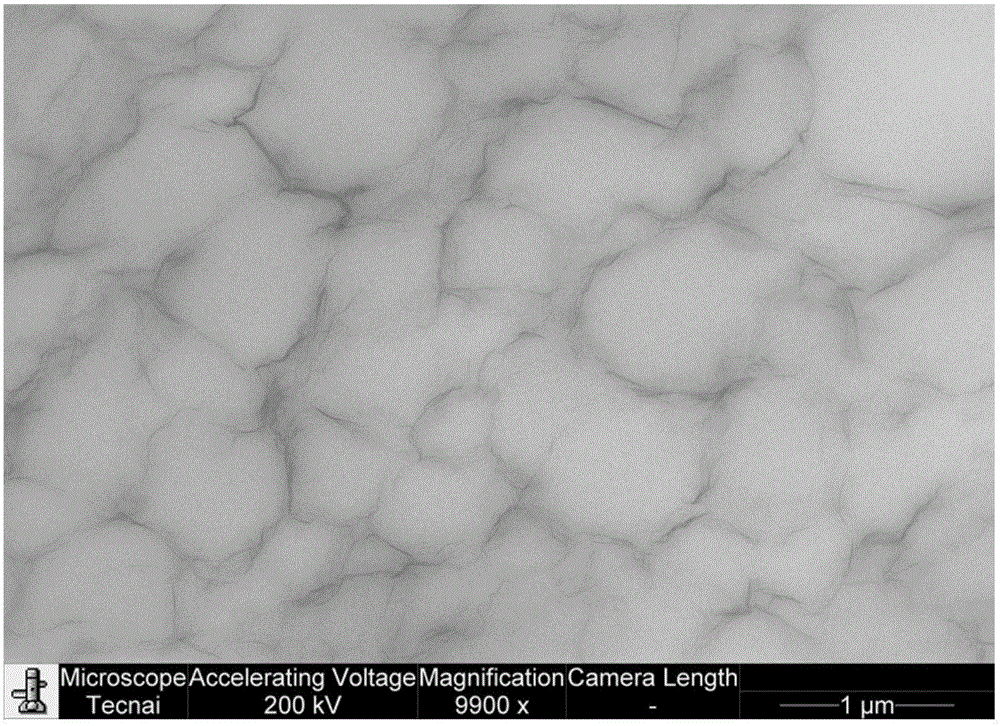

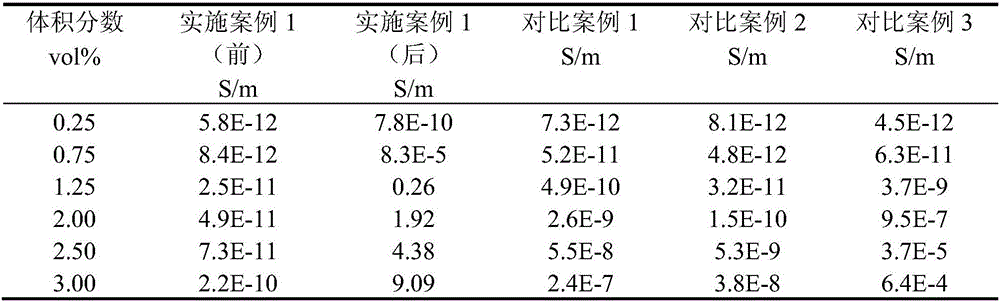

[0019] 0.2L, 0.6L, 1.0L, 1.6L, 2.0L, 2.4L of 0.5wt% graphene oxide aqueous solution (the contained graphene oxide quality is respectively 1g, 3g, 5g, 8g, 10g, 12g ) into the 167g natural rubber latex. After stirring evenly, add 20g sulfur water dispersion (10wt%), 100g ZnO water dispersion (1.0wt%) and 100g ZDC (1.0wt%) water dispersion and continue stirring. Pour the uniformly stirred mixed solution into a petri dish and place it in a blast drying oven at 50°C for 24h. The prepared membrane was directly soaked in hydroiodic acid solution (57wt%) for 8 hours at room temperature. After cleaning with deionized water, the membrane was dried again in a blast drying oven at 50 °C for 2 h. The filling volume fractions of graphene in the prepared composite materials are 0.25vol%, 0.75vol%, 1.25vol%, 2.00vol%, 2.50vol%, 3.00vol%, respectively. The electrical conductivity of each sample before and after reduction is shown in Table 1.

comparative example 1

[0021] Put 100g of solid natural rubber in an internal mixer at 60°C, add graphene powders with a mass of 0.6g, 1.8g, 3.0g, 4.8g, 6.0g, and 7.2g, respectively, and knead for 10 minutes. After adding 2g of sulfur, 1g of ZnO and 1g of solid vulcanization aids such as ZDC, continue mixing for 5 minutes. The mixed rubber was vulcanized on a flat vulcanizing machine with a temperature of 143°C and a pressure of 15MPa. The filling volume fractions of graphene in the prepared composite materials are 0.25vol%, 0.75vol%, 1.25vol%, 2.00vol%, 2.50vol%, 3.00vol%, respectively. The electrical conductivity of each sample is shown in Table 1.

comparative example 2

[0023] Hydrazine hydrate reduced graphene oxide (mass ratio: 7:10) to prepare a graphene aqueous solution with a concentration of 0.05 wt%. With 167g natural latex respectively with 1.2L, 3.6L, 6.0L, 9.6L, 12.0L, the graphene aqueous solution of 14.4L (the quality of contained graphene is respectively 0.6g, 1.8g, 3.0g, 4.8g, 6.0g , 7.2g) were mixed, stirred evenly and flocculated with 1wt% dilute hydrochloric acid. The volume fractions of graphene in the prepared composite materials were 0.25vol%, 0.75vol%, 1.25vol%, 2.00vol%, 2.50vol%, 3.00vol%, respectively. 2g of sulfur, 1g of ZnO and 1g of ZDC and other solid vulcanization aids are added through the mill. The mixed rubber was vulcanized on a flat vulcanizing machine with a temperature of 143 °C and a pressure of 15 MPa. The conductivity of the tested samples is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com