Fluorine-containing anti-fingerprint oil polymer and preparation thereof, and application of polymer in field of super-amphiphobic materials

A polymer, anti-fingerprint technology, applied in the coating and other directions, can solve the problems of weak super-amphiphobic surface adhesion, poor friction and washing resistance, etc., to achieve a simple post-processing process, reduce production costs, and improve durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Preparation of perfluoropolyether allyl alcohol

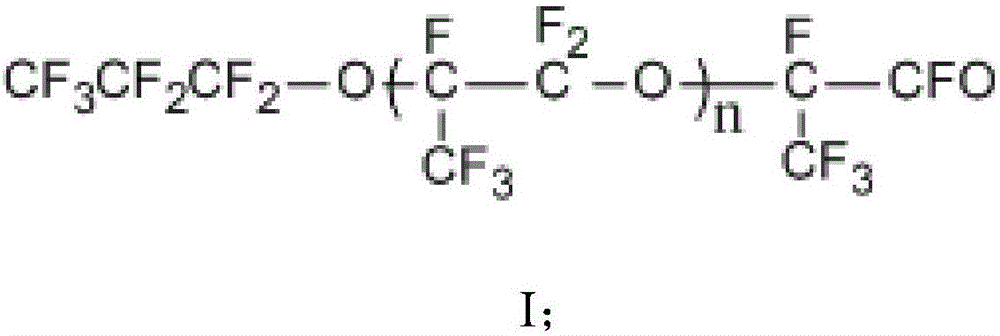

[0069] Add 10g of perfluoropolyether acid fluoride (abbreviation: PFPE-COF, molecular weight 2041, structural formula as formula I, n=10) into a 50mL round bottom flask, then dissolve PFPE-COF with 15mL CFC, and then add 2.8457g Allyl alcohol and 0.9916g of triethylamine, the reaction system was stirred and dissolved, and then the polymerization reaction was carried out at room temperature 40°C under stirring conditions for 5h; after the stirring reaction was completed, the product was filtered, the solvent was removed by rotary evaporation, and the unreacted The substance, the product sinks in acetone, then washes with water, and finally uses anhydrous sodium sulfate to dry overnight to remove water to obtain the product perfluoropolyether allyl alcohol;

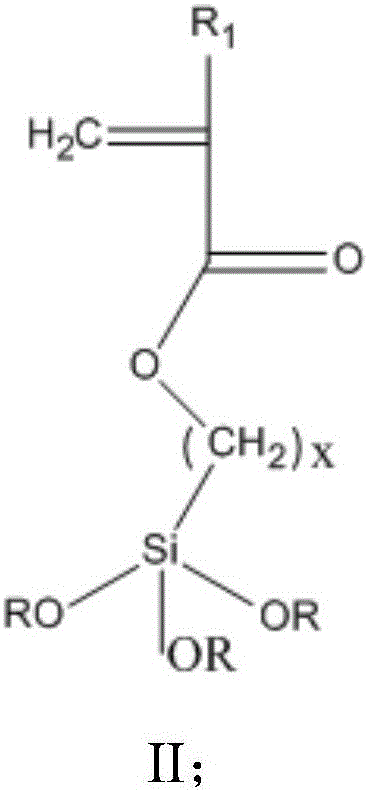

[0070] (2) Free radical copolymerization of perfluoropolyether allyl alcohol and 3-(acryloyloxy)propyltrimethoxysilane

[0071] Add 2g of perfluoropolyether ally...

Embodiment 2

[0073] (1) Preparation of perfluoropolyether allyl alcohol

[0074] Add 10g of perfluoropolyether acid fluoride (abbreviation: PFPE-COF, molecular weight 3347, structural formula as formula I, n=18) into a 50mL round bottom flask, then dissolve PFPE-COF with 15mL CFC, and then add 0.8676g Allyl alcohol and 0.3023g of triethylamine, the reaction system was stirred and dissolved, and then the polymerization reaction was carried out at room temperature 20°C under stirring conditions for 15 hours; after the stirring reaction was completed, the product was filtered, the solvent was removed by rotary evaporation, and the unreacted The substance, the product sinks in acetone, then washes with water, and finally uses anhydrous sodium sulfate to dry overnight to remove water to obtain the product perfluoropolyether allyl alcohol;

[0075] (2) Free radical copolymerization of perfluoropolyether allyl alcohol and 3-(acryloyloxy)propyltrimethoxysilane

[0076] Add 3g of perfluoropolyethe...

Embodiment 3

[0078] (1) Preparation of perfluoropolyether allyl alcohol

[0079] Add 10g of perfluoropolyether acid fluoride (abbreviation: PFPE-COF, molecular weight 4595, structural formula as formula I, n=25) into a 50mL round bottom flask, then dissolve PFPE-COF with 20mL CFC, and then add 0.126g 1.101g of allyl alcohol and 1.101g of triethylamine, the reaction system was stirred and dissolved, and then polymerized at 30°C for 14 hours; after the stirring reaction was completed, the product was filtered, the solvent was removed by rotary evaporation, and the unreacted The substance, the product sinks in acetone, then washes with water, and finally uses anhydrous sodium sulfate to dry overnight to remove water to obtain the product perfluoropolyether allyl alcohol;

[0080] (2) Free radical copolymerization of perfluoropolyether allyl alcohol and 3-(acryloyloxy)propyltrimethoxysilane

[0081] Add 4g of perfluoropolyether allyl alcohol prepared in step (1) into a 50mL round bottom flask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com