Preparation method of monoamine oxidase inhibitor

A technology for monoamine oxidase and inhibitors, which is applied in the field of preparation of monoamine oxidase inhibitors, can solve the problems of few types and obvious toxic and side effects of chemically synthesized preparations, and achieve good safety, easy popularization and application, and strong inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

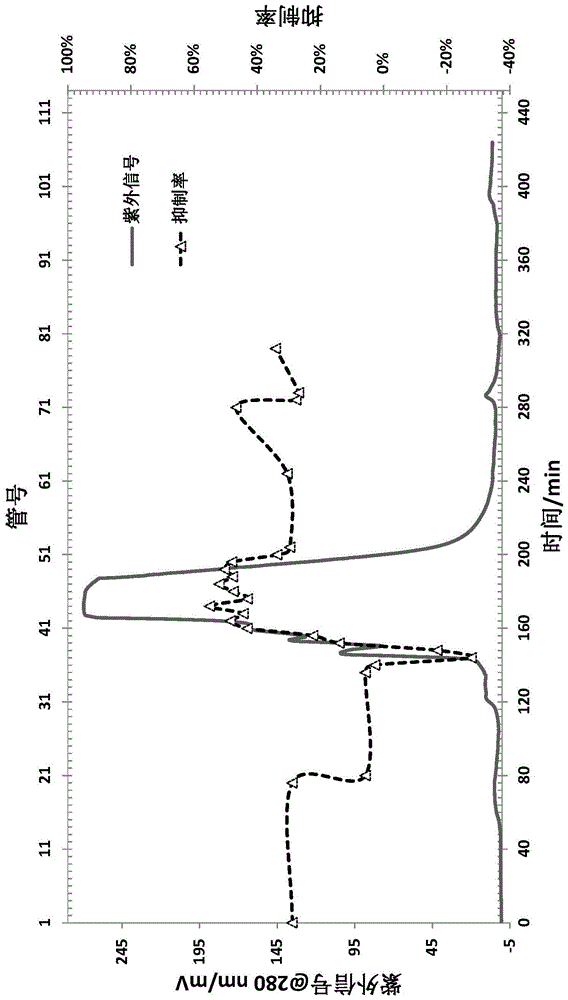

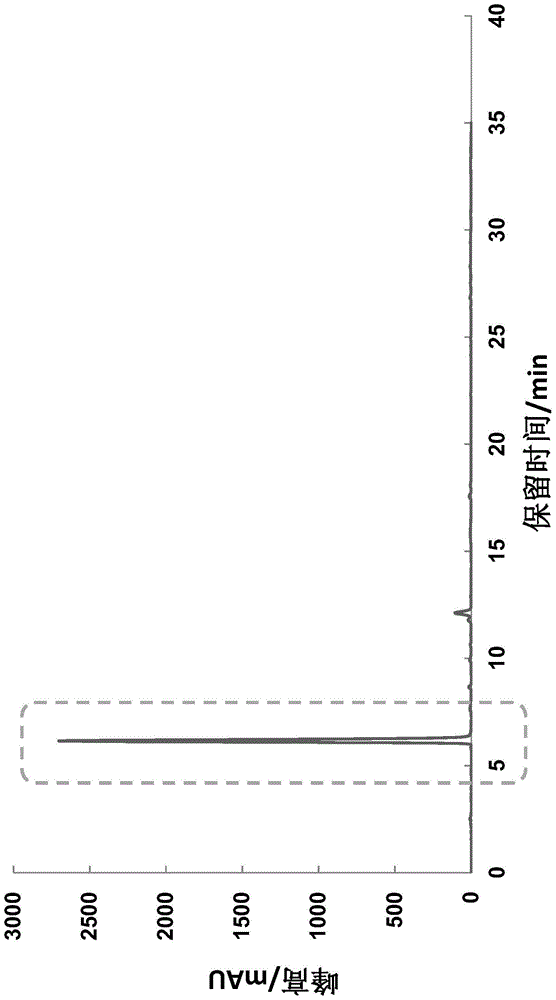

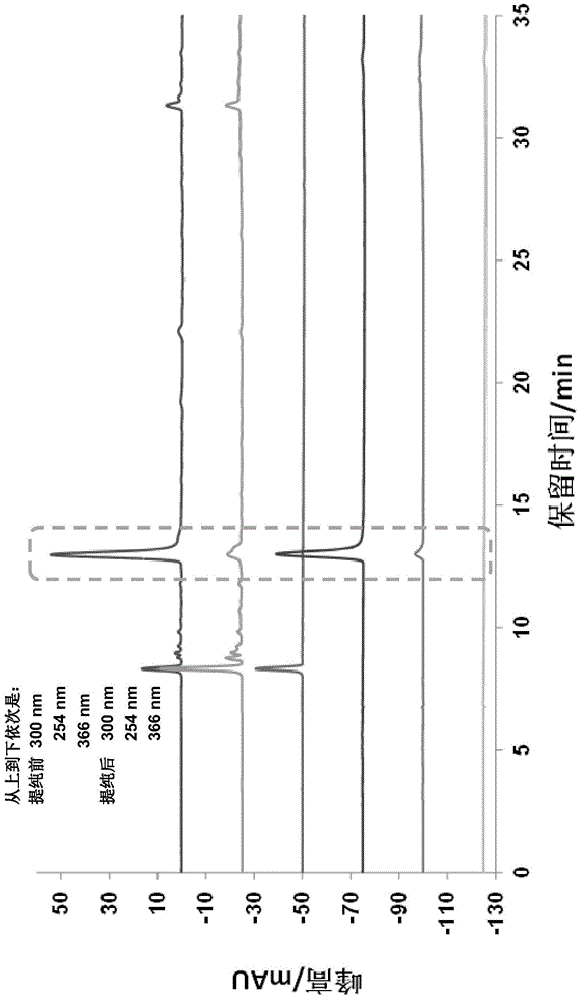

[0056] Example 1 Separation and purification of monoamine oxidase inhibitors from the MRS fermentation broth of Lactobacillus casei BDII

[0057] (1) prepare the fermented liquid of Lactobacillus casei BD-II:

[0058] Lactobacillus casei BD-II (CGMCC No.0849) frozen at -80°C was inoculated on the MRS plate and cultured anaerobically at 37°C for 48 hours; a single colony was picked from the plate and inoculated in 10 mL of MRS liquid medium at 37 The primary seed liquid of BD-II was obtained by anaerobic culture at ℃ for 12 hours; then the primary seed liquid was inoculated into 200mL MRS liquid medium with a 4% inoculum size for expanded culture, and the similar step-by-step expansion culture was carried out to 6L. In BIOTRONLiFlusSP_200L In a fully automatic fermenter at (35.5±0.5)°C, inoculate 6L of seed solution in 120LMRS medium for 24 hours according to 5% inoculum size, and ferment for 24 hours to obtain 126L of fermentation stock solution (pH up to 4.00, the number of c...

Embodiment 2

[0080] Example 2 Separation and purification of monoamine oxidase inhibitors from the skim milk fermentation broth of Lactobacillus casei ATCC334

[0081] (1) prepare the fermented liquid of Lactobacillus casei ATCC334:

[0082] Lactobacillus casei ATCC334 frozen at -80°C was inoculated on the MRS plate and cultured anaerobically at 37°C for 48 hours; a single colony was picked from the plate and inoculated in 5 mL of skim milk and cultured anaerobically at 37°C for 12 hours to obtain a strain of ATCC334 Grade seed liquid; then inoculate this grade 1 seed liquid into 200mL skim milk with 4% inoculum size to carry out expansion culture, similar step by step expansion culture to 6L, in BIOTRONLiFlusSP_200L automatic fermenter at (30.0 ± 0.5) ℃ Conditions: Inoculate 6L of seed liquid into 120L of skim milk and ferment for 48 hours according to 5% inoculum size, and obtain 126L of fermentation stock solution (pH reaches 4.53, and the number of colonies reaches 10 9 ).

[0083] (...

Embodiment 3

[0097] Example 3 Separation and purification of monoamine oxidase inhibitors from the skim milk fermentation broth of Lactobacillus bulgaricus LB340

[0098] (1) prepare the fermented liquid of Lactobacillus bulgaricus LB340:

[0099] Lactobacillus bulgaricus LB340 [DuPont Danisco (China) Co., Ltd.] frozen at -80°C was inoculated on the MRS plate and cultured anaerobically at 37°C for 48 hours; a single colony was picked from the plate and inoculated in 10 mL of skim milk in The primary seed liquid of LB340 was obtained by anaerobic culture at 37°C for 12 hours; then the primary seed liquid was inoculated into 200mL skim milk with a 4% inoculum size for expanded culture, and the similar step-by-step expansion culture was carried out to 6L, and the BIOTRONLiFlusSP_200L automatic In a fermenter at (40.0±0.5)°C, inoculate 6L of seed liquid into 120L of skim milk and ferment for 24 hours according to the inoculum size of 5%, to obtain 126L of fermentation stock solution (pH up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com