Preparation of cobalt sulfide nanomaterial and method for detecting hydrogen peroxide

A technology of nanomaterials and hydrogen peroxide, which is applied in the direction of cobalt sulfide, chemical instruments and methods, and analysis by making materials undergo chemical reactions, can solve the problems of low detection limit, high detection limit, easy inactivation, etc., and achieve detection Fast speed, high accuracy, and good specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

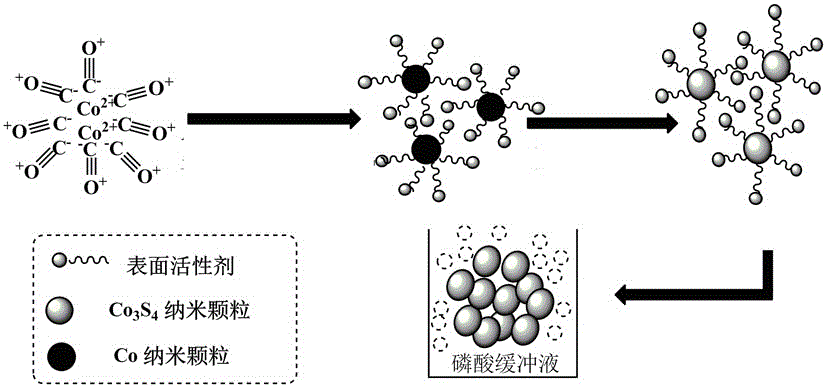

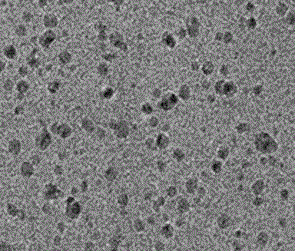

[0022] Such as figure 1 As shown, add 12-18 ml of o-dichlorobenzene, 0.1-0.2 ml of oleic acid, and 0.1-0.3 g of trioctylphosphine oxide in sequence in a closed reaction bottle, then pass through argon to exhaust the air in the device, and then slowly raise the temperature To 187 ℃, quickly add 2-5 mL o-dichlorobenzene solution containing 0.4-0.6 g cobalt carbonyl to the reaction flask with a pipette gun. The molecular formula of cobalt carbonyl is Co 2 (CO) 8 , maintaining the reaction temperature at 182 °C for 30 min to obtain a nano-cobalt colloidal solution. Then add 2-5 mL o-dichlorobenzene solution containing a certain amount of sulfur into the nano-cobalt colloid solution, the amount of sulfur added here depends on the amount of cobalt carbonyl added, so that the molar ratio of cobalt to sulfur is 3:4 , after continuing to react for 2.5h, a nanoparticle cobalt sulfide dispersion solution was obtained. After the reaction solution is cooled to room temperature, it is wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com