Fault monitoring and early warning system and method for belt conveyor of mine

A technology of belt conveyor and early warning system, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as personal accidents, labor and time-consuming, and prone to failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

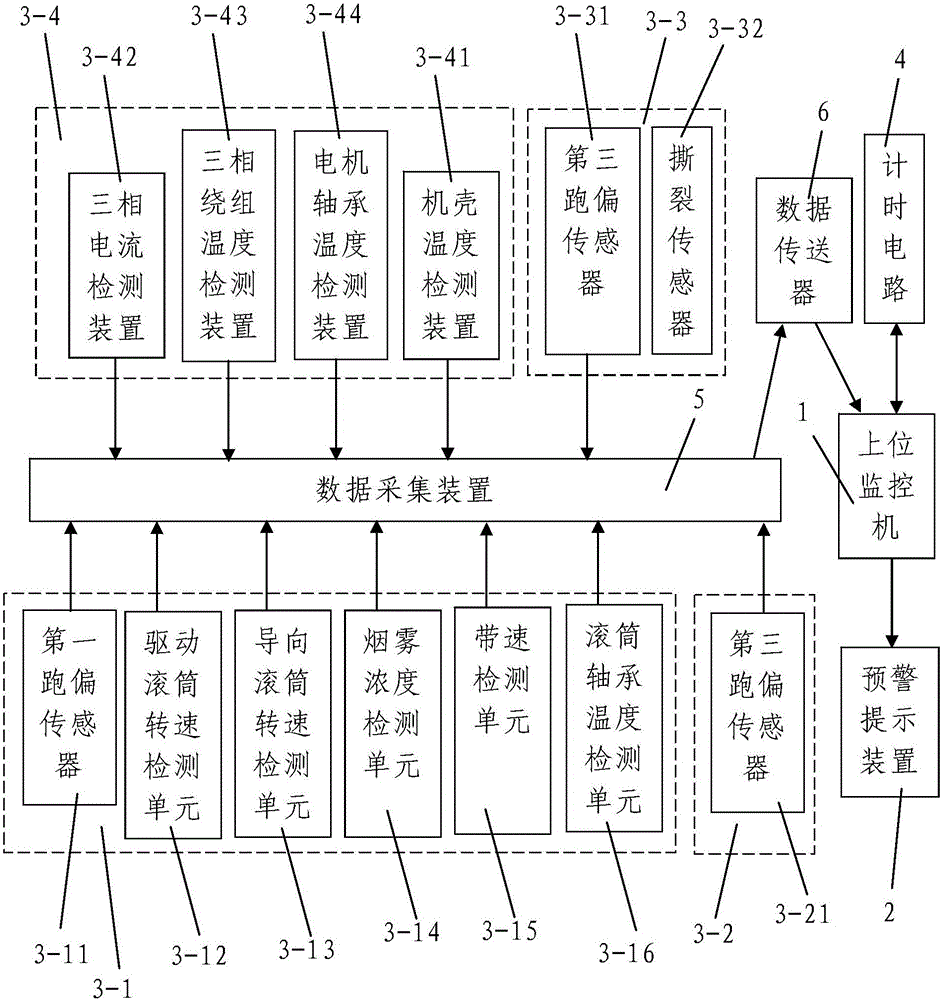

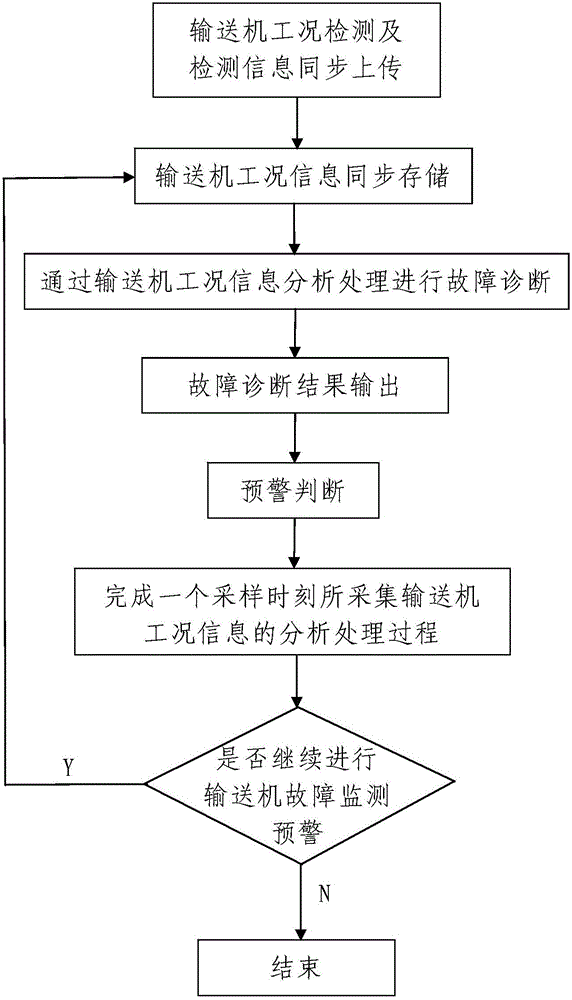

[0070] Such as figure 1 The shown a mine belt conveyor fault monitoring and early warning system includes a host monitoring machine 1, a conveyor working condition detection device for real-time detection of the working condition of the monitored belt conveyor, and the conveyor working condition detection device. The data acquisition device 5 connected to the device, the early warning prompting device 2 controlled by the upper monitoring machine 1 and the timing circuit 4 connected with the upper monitoring machine 1, the early warning prompting device 2 and the data acquisition device 5 are all connected with the upper monitoring machine 1 ; The monitored belt conveyor is a belt conveyor installed in the coal mine underground roadway.

[0071] The conveyor working condition detection device includes a motor working condition detection device 3-4, a head working condition detection device 3-1 arranged at the head of the belt conveyor to be monitored, and a machine tail of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com