Door seal die for washing machine

A washing machine and mold technology, which is applied in the field of washing machine door seal molds, can solve the problems of external springs that are easy to hurt people, high friction of the slider, and short service life, and achieve the effects of easy heat treatment, reduced friction, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

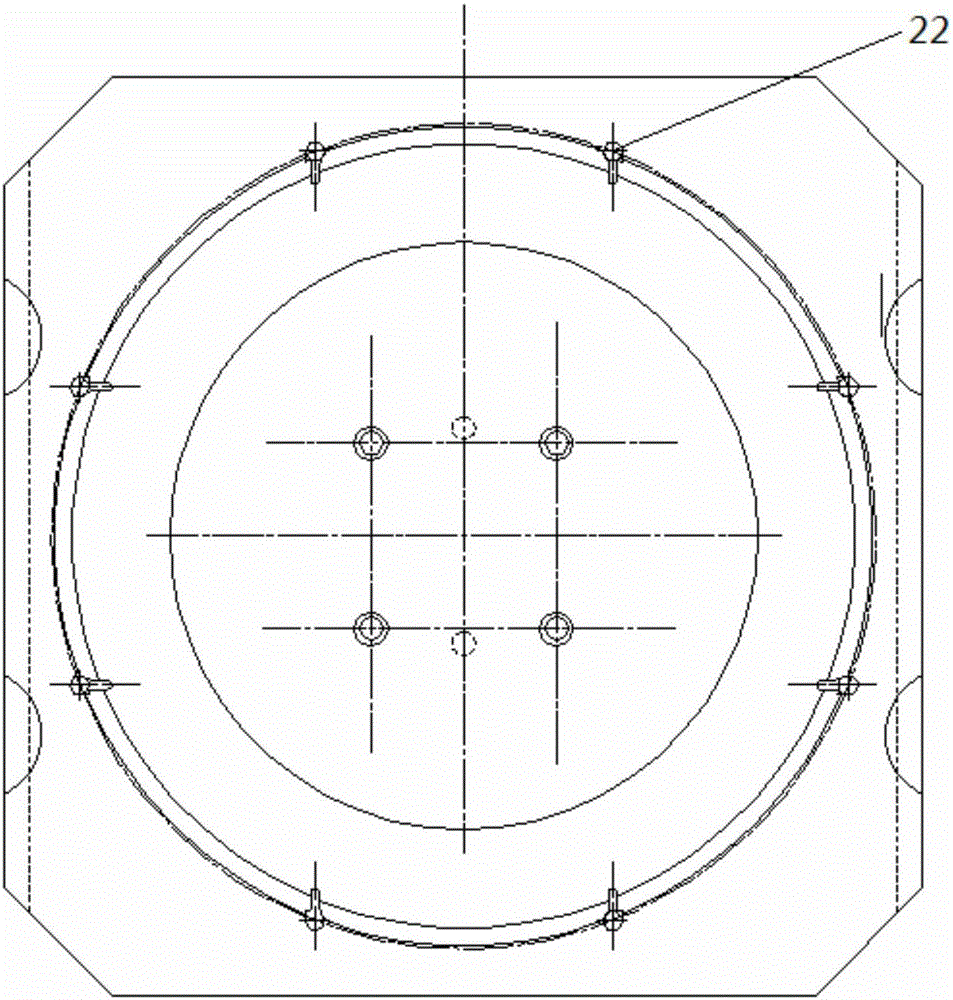

[0031] A washing machine door seal mold, such as Figure 1 to Figure 5 As shown, it includes an injection mold cavity composed of upper mold 1, the first upper mold core 2, the second upper mold core 3, the lower mold 11, the lower mold core 14, the middle mold 8 and the middle core 13; the middle core 13 is set Between the upper mold 1 and the lower mold 11, the first upper mold core 2 and the second upper mold core 3 are arranged on the upper mold 1, the lower mold core 14 is arranged on the lower mold 11, and the center core 13 is arranged on the upper mold through the tie rod 5. On the mold 8, an upper half module 7 is arranged above the middle mold 8, a lower half module 10 is arranged under the middle mold 8, and an injection nozzle 6 is arranged on the upper mold 1.

[0032] In the above embodiment, upper mold 1 is provided with upper mold positioning pin 4 .

[0033] In the above embodiment, there are at least four positioning pins 4 of the upper mold, and tie rods 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com