Five-axis linkage type hybrid machine tool

A five-axis linkage and hybrid technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve the effect of high modularity, simple structure and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

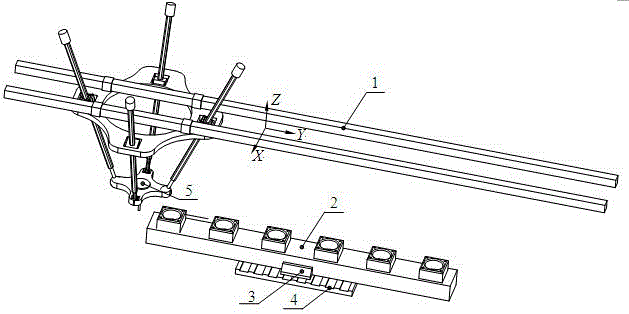

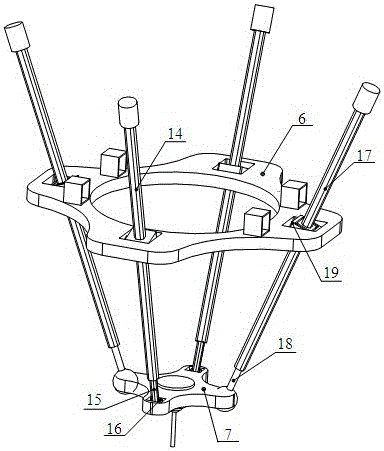

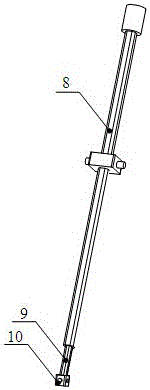

[0021] like figure 1 As shown, the five-axis linkage hybrid machine tool includes long straight guide rail 1, parallel module, worktable 4, fixture 3, tool 5 and other parts. where the structure of the parallel modules, such as figure 2 As shown, it includes connecting the first and third branch chains with the same structure between the basic platform 6 and the moving platform 7, and the second and fourth branch chains with the same structure, the basic platform 6 and the moving platform 7, and each part forms a Spatial parallel closed-loop mechanism. The first branch chain, the second branch chain, the third branch chain, and the fourth branch chain all contain an actively driven kinematic pair, and the hinge center points of the upper end of each branch chain with the base platform 6 and the lower end with the moving platform 7 are on each pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com