Method for adjusting gravity center of workpiece in large range

A large-scale, workpiece-based technology, applied to metal processing machinery parts, manufacturing tools, large fixed members, etc., can solve problems such as difficult force, locking, excessive force on the ellipse of the workpiece end face, etc., to achieve uniform force, reduce The effect of being locked in a small way and increasing the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

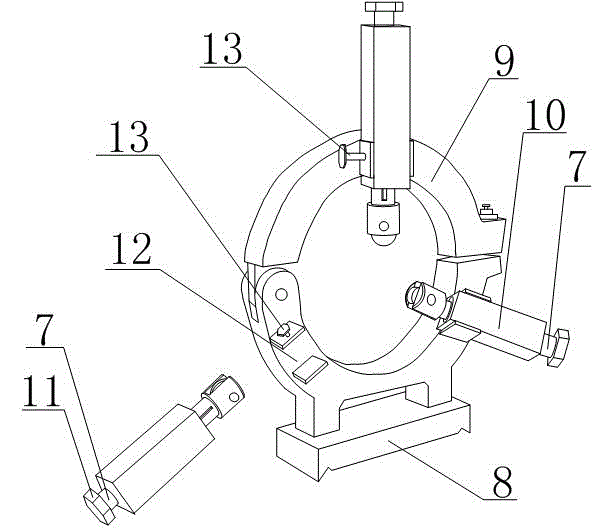

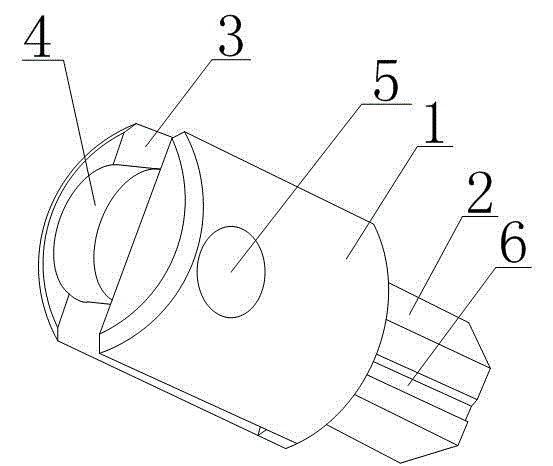

[0019] like Figures 1 to 2 As shown in the figure, a method for adjusting the center of gravity of a workpiece in a large range of the present invention includes a mounting seat 8, a center frame body 9 is arranged on the mounting seat 8, and three evenly distributed clamping grooves are arranged on the side wall of the center frame body 9. 12. An adjusting cylinder 10 is installed in the clamping slot 12, and a fixing bolt 13 is arranged on the side wall of the clamping groove 12. The fixing bolt is used to change and fix the relative positional relationship between the adjusting cylinder and the center frame body 9. On the adjusting cylinder 10 A turntable 11 is provided, the turntable 11 is connected with the top wheel through the screw 7 in the adjusting cylinder 10, and the top wheel is installed at one end of the three adjusting cylinders 10 located on the inner side of the center frame body 9, and the top wheel includes the top cylinder 1, the top cylinder 1 The whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com