High-hydrophilic compound reverse osmosis membrane and preparation method of high-hydrophilic compound reverse osmosis membrane

A technology of reverse osmosis membrane and hydrophilicity, which is applied in the field of highly hydrophilic composite reverse osmosis membrane and its preparation, can solve the problems of poor hydrophilicity, etc., and achieve the goals of improved hydrophilicity, wide application value, and improved preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Disperse graphene oxide in N,N-dimethylformamide by ultrasonic wave, and disperse by ultrasonic wave for 2 hours to form a uniform and stable dispersion solution. Add ethylene glycol methyl ether to the dispersion solution, stir and mix evenly, and slowly add polysulfone Form the feed liquid in the dispersion solution, then raise the temperature of the feed liquid to 80°C, continue stirring and dissolving for 6 hours, then let it stand for degassing for 16 hours to form a uniform and stable casting solution, and the contents of the components in the casting solution are as follows: : Graphene oxide 1%, N,N-dimethylformamide 73%, ethylene glycol methyl ether 8%, polysulfone 18%.

[0034] The casting solution forms a liquid primary film on the non-woven fabric through a scraper, and undergoes a phase inversion to form a solid film through a pure water gel bath at 18°C. The solid film is then washed through cleaning tanks with water temperatures of 25°C and 60°C in sequence...

Embodiment 2

[0037] Disperse graphene oxide in N,N-dimethylformamide by ultrasonic wave, and disperse by ultrasonic wave for 2 hours to form a uniform and stable dispersion solution. Add ethylene glycol methyl ether to the dispersion solution, stir and mix evenly, and slowly add polysulfone Form the feed liquid in the dispersion solution, then raise the temperature of the feed liquid to 80°C, continue stirring and dissolving for 6 hours, then let it stand for degassing for 16 hours to form a uniform and stable casting solution, and the contents of the components in the casting solution are as follows: : 2% graphene oxide, 72% N,N-dimethylformamide, 8% ethylene glycol methyl ether, 18% polysulfone.

[0038] The casting solution forms a liquid primary film on the non-woven fabric through a scraper, and undergoes a phase inversion to form a solid film through a pure water gel bath at 18°C. The solid film is then washed through cleaning tanks with water temperatures of 25°C and 60°C in sequence...

PUM

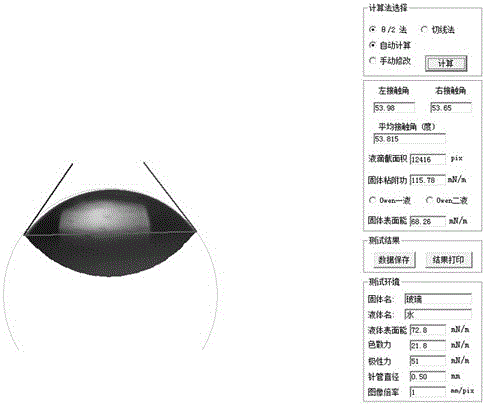

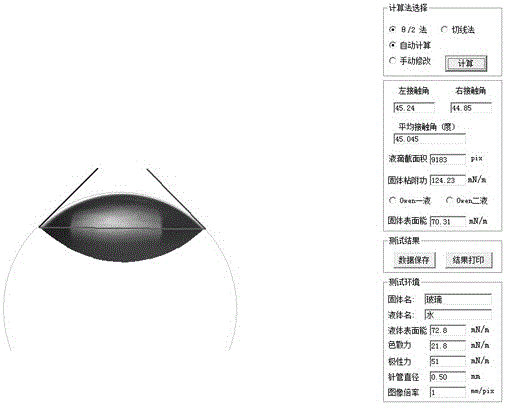

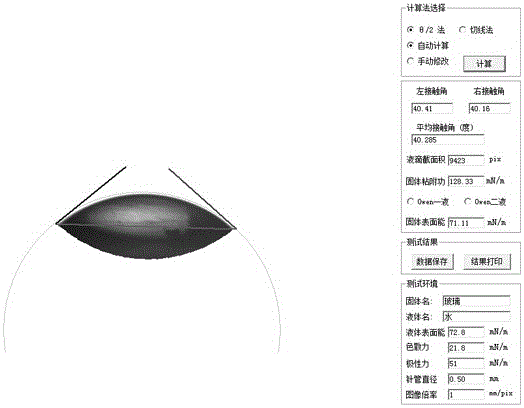

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com