Application of self-assembled micelles of amphiphilic copolymer containing thymine as emulsifier

A technology of thymine and copolymer, which is applied in the directions of medical preparations containing active ingredients, preparations for skin care, and medical preparations without active ingredients, etc., to achieve the effect of strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of PSVM polymer self-assembled micelles

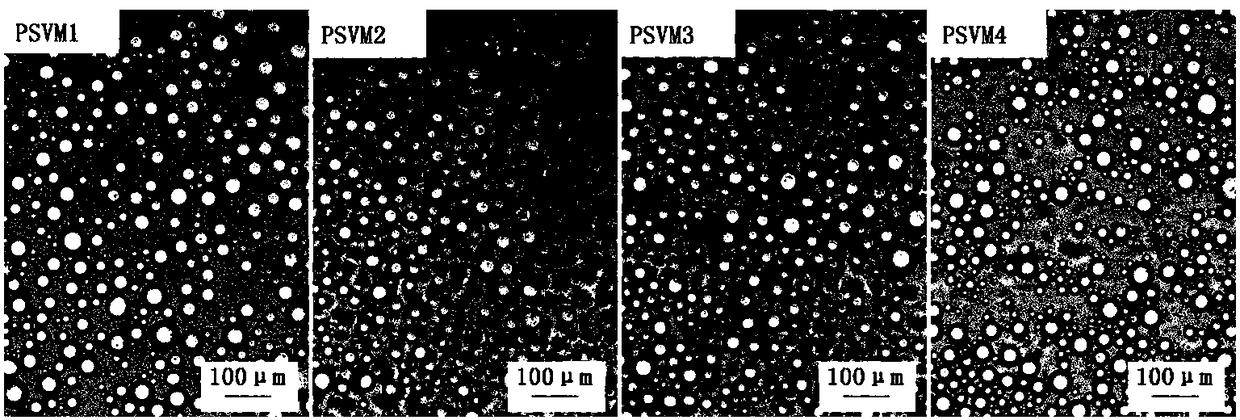

[0034] Amphiphilic copolymers PSVM1-PSVM4 with thymine contents of 4.48wt%, 9.42wt%, 20.24wt%, and 25.73wt% were dissolved in the solvent DMF to obtain a polymer solution with a mass concentration of 50 mg / mL. Add deionized water dropwise at a rate of 30 μL / min until blue opalescence appears, stop adding water, continue stirring for 3 h, drop the blue opalescent solution into a large amount of deionized water under stirring conditions to fix the micellar structure, and then After stirring for 3 hours, the solution was transferred to a dialysis bag, dialyzed with deionized water for 5 days, and the water was changed every 6 hours to remove DMF, and the finally obtained four PSVM micellar aqueous solutions were adjusted to the desired concentration.

[0035] (2) Preparation of PSVM self-assembled micelles stabilized emulsion

[0036] Set the concentration of the four micellar aqueous solutions PSVM1-PSVM4 to 2mg / m...

Embodiment 2

[0039] (1) Preparation of PSVM polymer self-assembled micelles

[0040] Dissolve the thymine-containing amphiphilic copolymer PSVM in the solvent DMF to obtain a polymer solution with a mass concentration of 50 mg / mL, add deionized water dropwise to it at a rate of 30 μL / min under magnetic stirring until blue opalescence appears, and stop Add water, continue to stir for 2 hours, drop the blue opalescent solution drop by drop into a large amount of deionized water under stirring conditions to fix the micellar structure, and then transfer the solution to a dialysis bag after stirring for 3 hours, and dialyze with deionized water for 5 days. The water was changed every 6 hours to remove DMF, and the finally obtained aqueous solution of PSVM micelles was adjusted to the desired concentration.

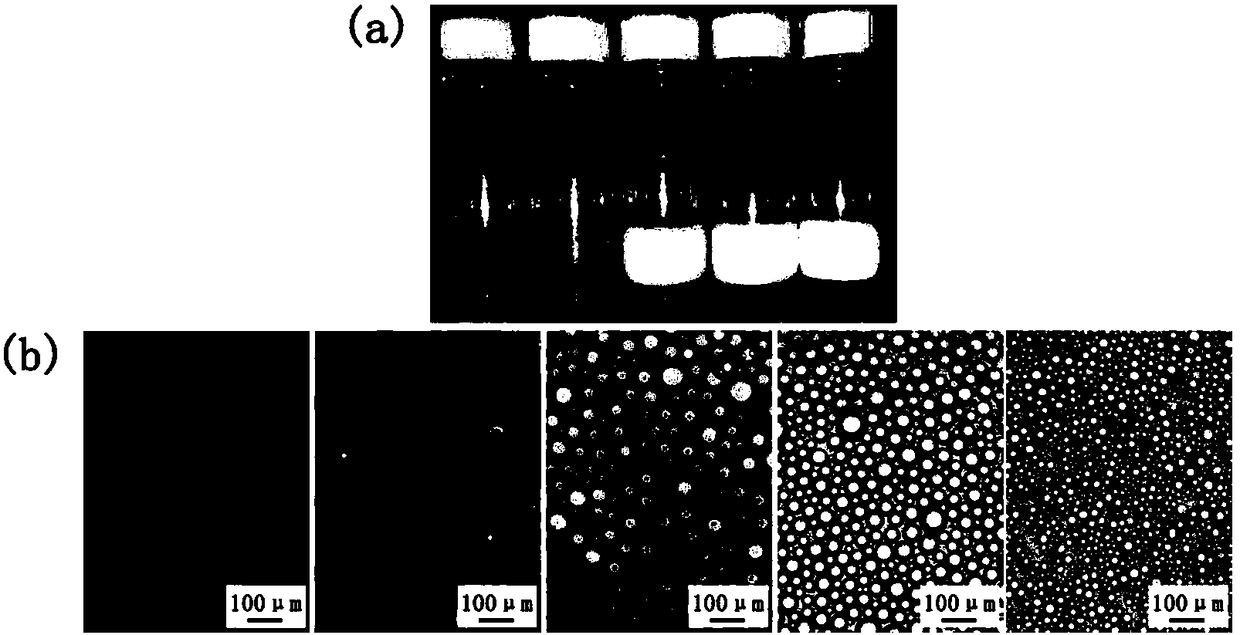

[0041] (2) Preparation of PSVM self-assembled micelles stabilized emulsion

[0042] Take 3mL prepared micellar aqueous solutions with different concentrations (0.2-5mg / mL) and white oil of...

Embodiment 3

[0045] (1) Preparation of PSVM self-assembled micelles, the method is the same as step (1) in Example 2.

[0046] (2) Preparation of PSVM self-assembled micelles stabilized emulsion

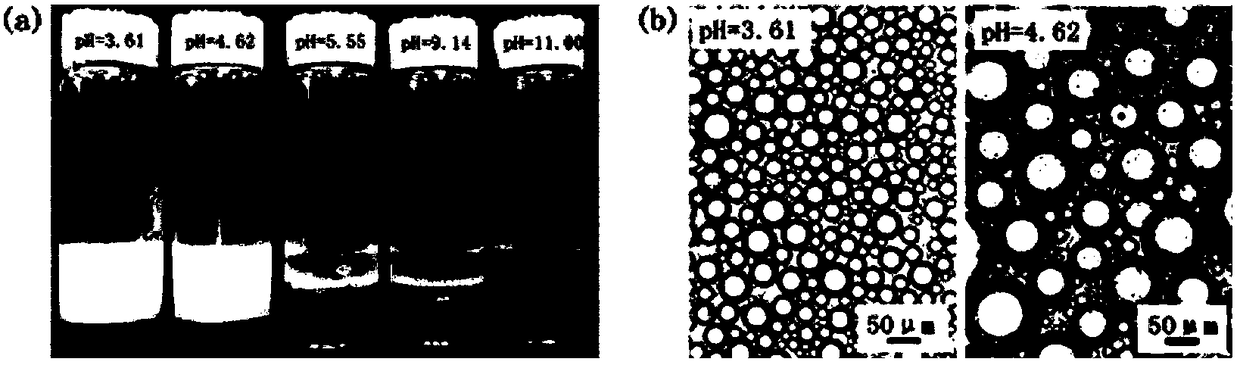

[0047] Set the concentration of the micellar aqueous solution to 2mg / mL, use a small amount of HCl and NaOH to adjust the pH of the micellar aqueous solution to 3.61-11.00, take 3mL of PSVM micellar aqueous solution with different pH and an equal volume of white oil in an emulsification bottle, Use a high-speed disperser to homogenize for 2 minutes at a speed of 20,000 r / min, and after standing for 24 hours, the desired emulsion is obtained.

[0048] image 3 Digital photographs and optical microscope images of PSVM micelles stabilized at different pH. It can be seen from the figure that when the pH ≤ 4.62, a stable oil-in-water emulsion can be formed, and the particle size of the emulsion increases with the increase of pH; when the pH ≥ 5.55, the emulsion breaks. Therefore, the formation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com