Method for processing raw dark green tea

A processing method and technology for black hair tea, applied in the field of tea processing, can solve problems such as consumer acceptance, and achieve the effects of improving bitterness, bitterness and aroma, and enhancing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 The research of the main parameters of the processing technology

[0024] With Baojing Golden Tea No. 1, one bud, three, and four fresh leaves of Baojing Golden Tea Factory Base, Baojing Golden Village, Hulu Town, Baojing County, Jishou City, Hunan Province, as test material, adopt the prior art to each parameter in this processing method, such as The number of times of greening, the time of fermenting, the time of stacking, and the drying method were studied. The results are shown in Table 1-Table 12 below:

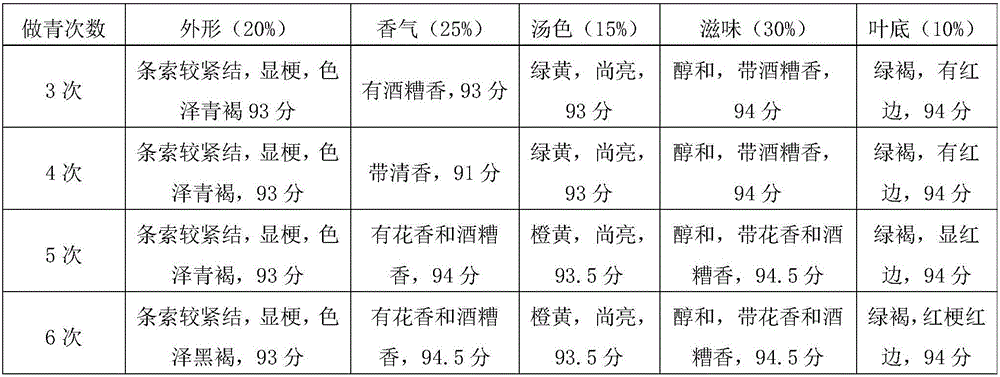

[0025] Table 1 The influence of greening times on the sensory evaluation results of tea

[0026]

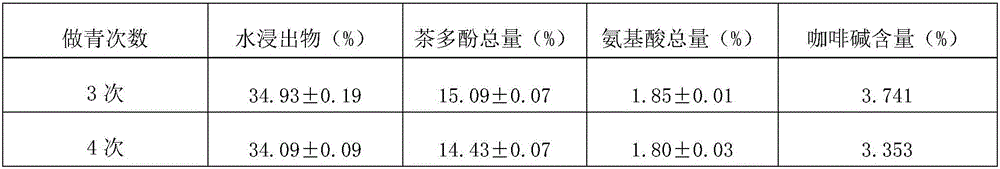

[0027] Table 2 The influence of greening times on the main quality components of tea

[0028]

[0029]

[0030] Table 3 The influence of greening frequency on catechin components in tea leaves

[0031]

[0032] Table 4 Effect of fermenting time on sensory evaluation of tea

[0033]

[0034] Table 5 Effect of fermenting time on the main ...

Embodiment 2

[0054] The fresh leaves of Baojing Golden Tea No. 1 spring with one bud and two leaves from the base of Baojing Golden Tea Factory in Huangjin Village, Hulu Town, Baojing County, Jishou City, Hunan Province are used as raw materials, and the fresh tea leaves are thinly spread on cotton cloth to make the fresh tea leaves even Under the sun's rays, take the method of drying and cooling twice, so that the fresh tea leaves wither evenly. The withering time is 30 minutes. Spread the withered leaves on the water sieve for natural cooling for 40 minutes and dry them in the air; Stand still (spread evenly on the water sieve and stand still, stand still 60min each time) the sequence step is repeated 4 times to make green, make tealeaves edge turn red, send out floral fragrance or fruity fragrance. Stack the green leaves in bamboo baskets, cover the green leaves with a damp cloth to ferment, the thickness of the leaf pile is 25cm, the fermentation time is 2 hours, and turn once during t...

Embodiment 3

[0056] The fresh tea leaves are evenly spread in the withering tank with the leaves of Qi Xiashu in Yuntai Mountain in Anhua County as raw materials, and the fresh tea leaves are evenly spread in the withering tank. The thickness of the spread leaves is 10 cm, and the withering temperature is 32 ° C. In a drooping state, the green energy fades, and the fragrance of flowers is revealed. Spread the withered leaves in the withering trough and blow cold air to dissipate heat to dry the green leaves for 30 minutes. Then shake green (using 6CWL-90 type speed-regulating wave green machine to shake green, 5 shake green times are respectively 1min, 5min, 10min, 15min, 20min), stand still (spread evenly on the water sieve and stand still, every Stand still 75min) sequential steps repeat 5 times and do green, make tealeaves leaf edge turn red, send out floral fragrance or fruity fragrance. Stack green leaves in bamboo baskets, cover green leaves with a damp cloth to ferment, make green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com