A kind of flexible circuit board and its display

A technology of flexible circuit boards and flexible circuit substrates, which is applied in the direction of flexible printed circuit boards, printed circuits, printed circuits connected with non-printed electrical components, etc., can solve the problems of FPC thickness, reduce the overall thickness, Save installation space and improve space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

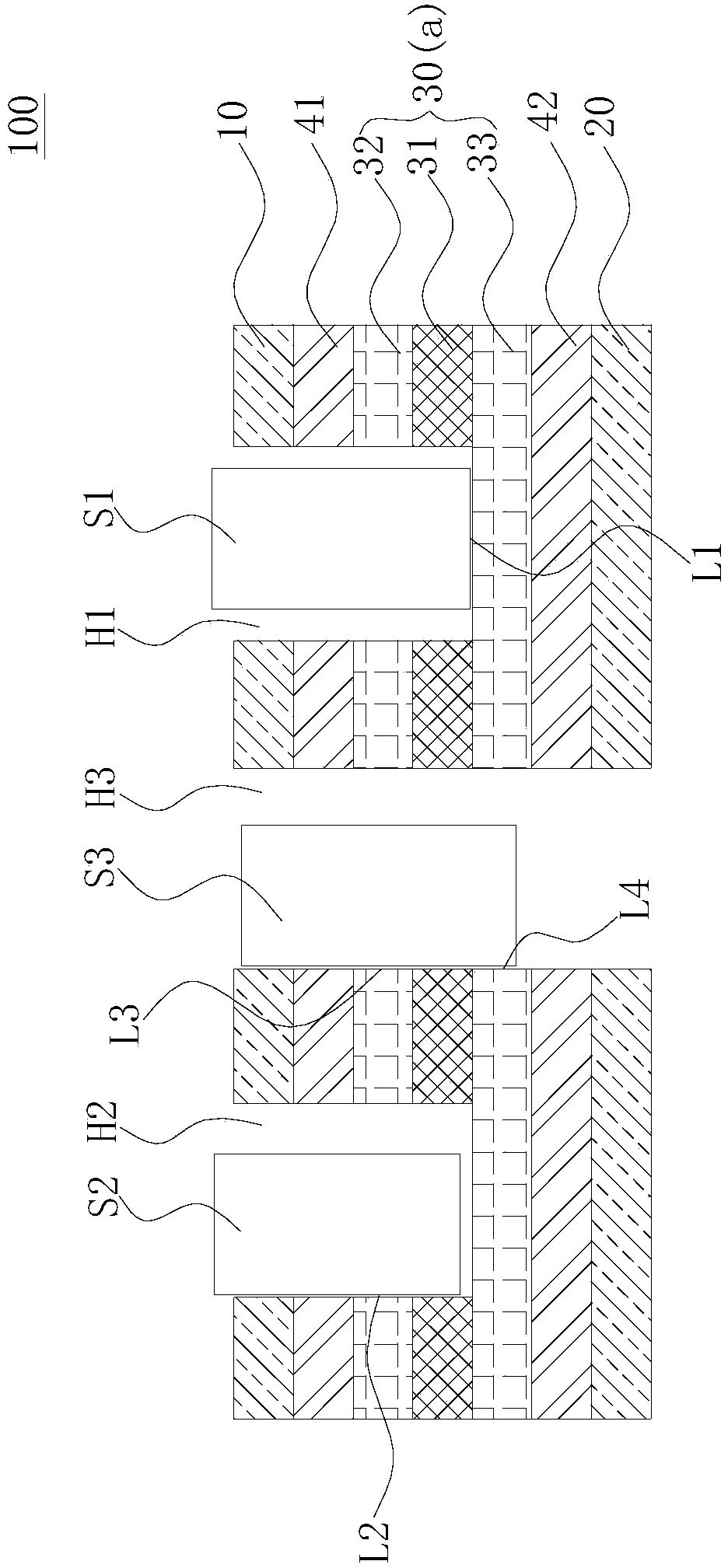

[0017] Such as figure 1 as shown, figure 1 It is a cross-sectional view of the flexible circuit board of Embodiment 1. The flexible circuit board 100 of Embodiment 1 includes a first insulating protection layer 10 and a second insulating protection layer 20 stacked oppositely, and is stacked between the first insulating protection layer 10 and the second insulating protection layer 20. The flexible circuit substrate 30 between the second insulating and protective layers 20 , and the components S1 , S2 , S3 electrically connected to the flexible circuit substrate 30 .

[0018] The flexible circuit substrate 30 includes at least one flexible substrate layer and at least two conductive layers.

[0019] In this embodiment, the flexible circuit substrate 30 includes a first flexible substrate unit 30a, the first flexible substrate unit 30a includes n layers of flexible substrate layers 31 and (n+1) layers of conductive layers 32, 33, and has a flexible substrate The structure in ...

Embodiment 2

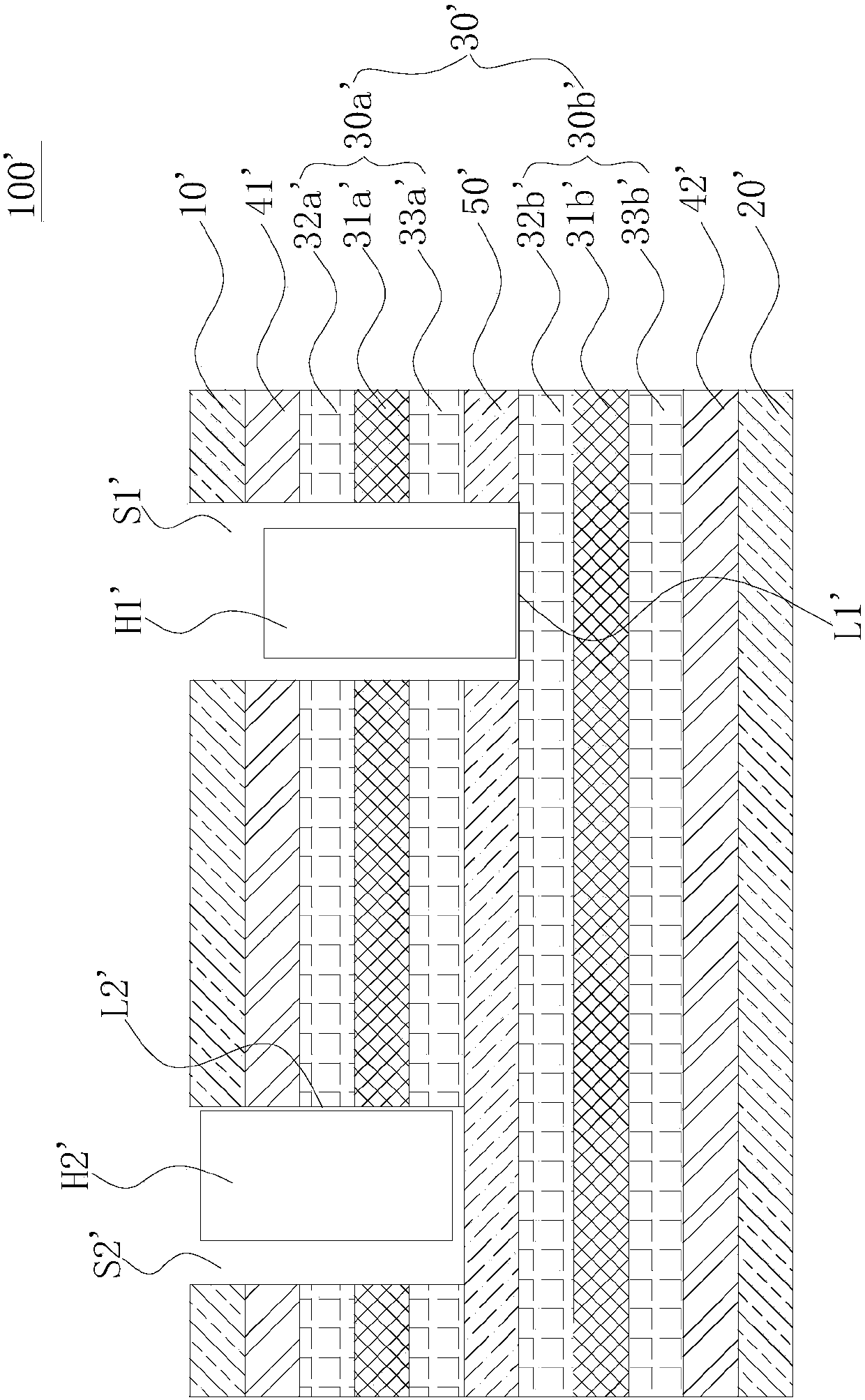

[0042] Such as figure 2 As shown, the flexible circuit board 100' of Embodiment 2 includes a first insulating protection layer 10' and a second insulating protection layer 20' that are stacked oppositely, and is stacked on the first insulating protection layer 10' and the second insulating protection layer. The flexible circuit substrate 30' between the layers 20', and the components S1', S2' electrically connected to the flexible circuit substrate 30'.

[0043] The flexible circuit substrate 30' includes two first flexible substrate units: a first flexible substrate unit 30a' at a shallower position and a first flexible substrate unit 30b' at a deeper position, with an insulating layer 30c interposed between them. ' separated.

[0044] The two first flexible substrate units 30a', 30b' are formed by covering the upper and lower sides of a flexible substrate layer with a conductive layer, which is the same as the first flexible substrate unit 30a in Embodiment 1, specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com