Lithium ion battery with thermal sensitive layer

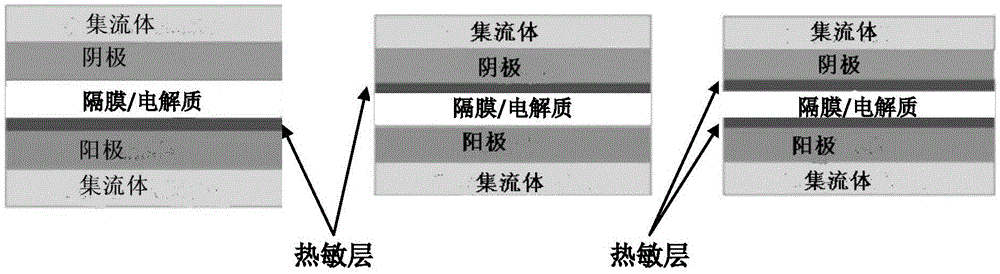

A lithium-ion battery and heat-sensitive layer technology, applied in the field of heat-sensitive layers, can solve problems such as short circuit, exposed electrodes, and diaphragm failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

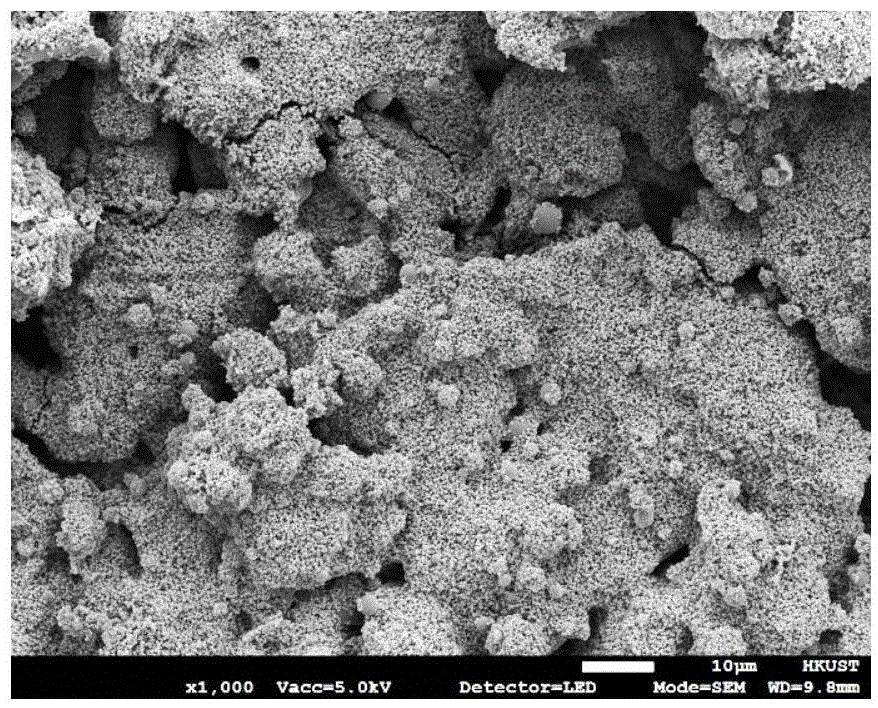

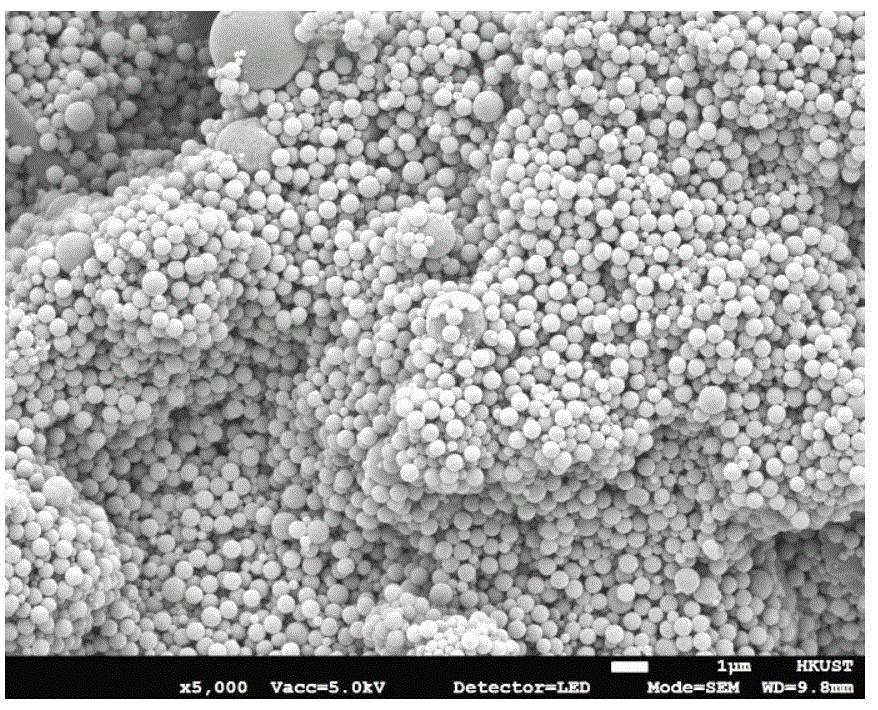

[0040] Polystyrene (PS) particles of 400 nm were dispersed in ethanol at a concentration of 1 wt%. The PS particle dispersion was coated on the graphite anode using a spray gun. Figure 2a with 2b is the SEM image of the PS particles coated on graphite anode and observed at close range. A uniform thermosensitive layer of PS particles completely covering the anode was prepared. After coating the polymer particles, the coated anode, cathode, PP / PE / PP three-layer separator, and LiPF 6 The electrolyte solution is used to make a pouch battery, in which a heat-sensitive layer is placed between the electrodes and the separator. A control pouch cell was similarly made without the polymer particle coating for comparison.

[0041] The pouch cell was first cycled at room temperature to verify cell performance. The voltage and current of the PS-coated pouch cell and the control cell were monitored over time, and their performance at room temperature was Figure 3a with 3b are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com