Method and system for monitoring insulation level of substation power cable

A power cable and insulation level technology, which is applied in the field of online monitoring of power cable insulation, can solve problems such as relay protection misoperation, difficulty in accurate detection, and strict requirements on AC signal amplitude, so as to ensure system safety and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

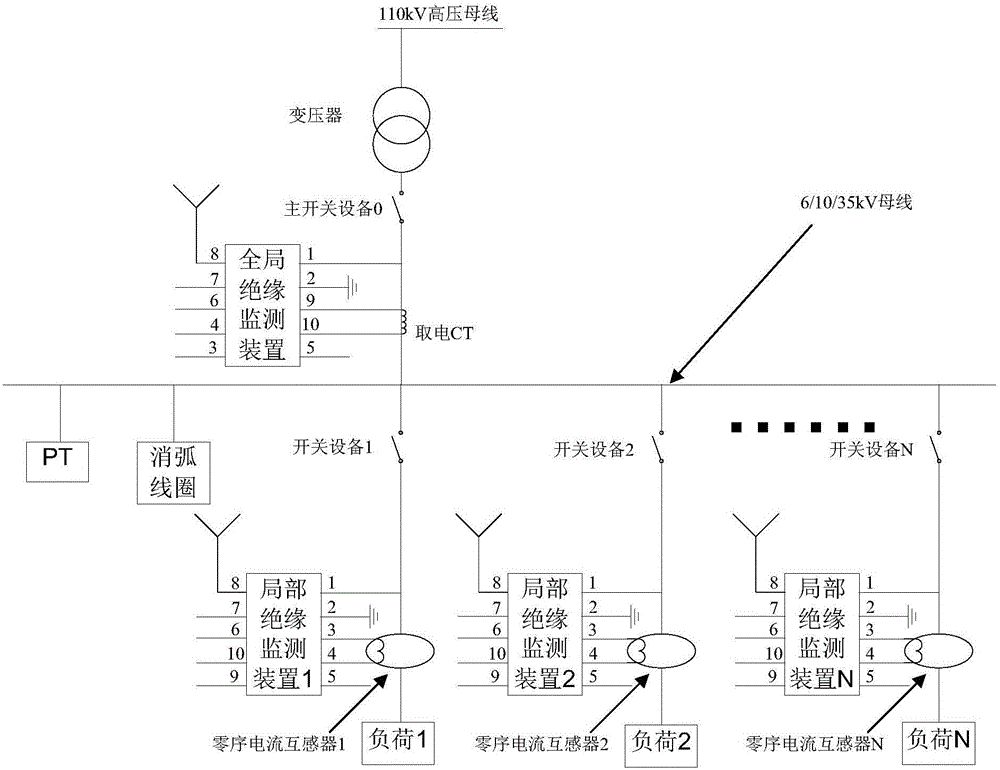

[0087] The insulation monitoring system includes the following parts: 6 / 10 / 35kV high-voltage bus, power cables, 1 three-phase transformer, N+1 power cable insulation monitoring devices (including 1 global power cable insulation monitoring device and local power cable insulation monitoring devices N units), 1 main switchgear, N feeder branch switchgears, N zero-sequence current transformers, and N loads.

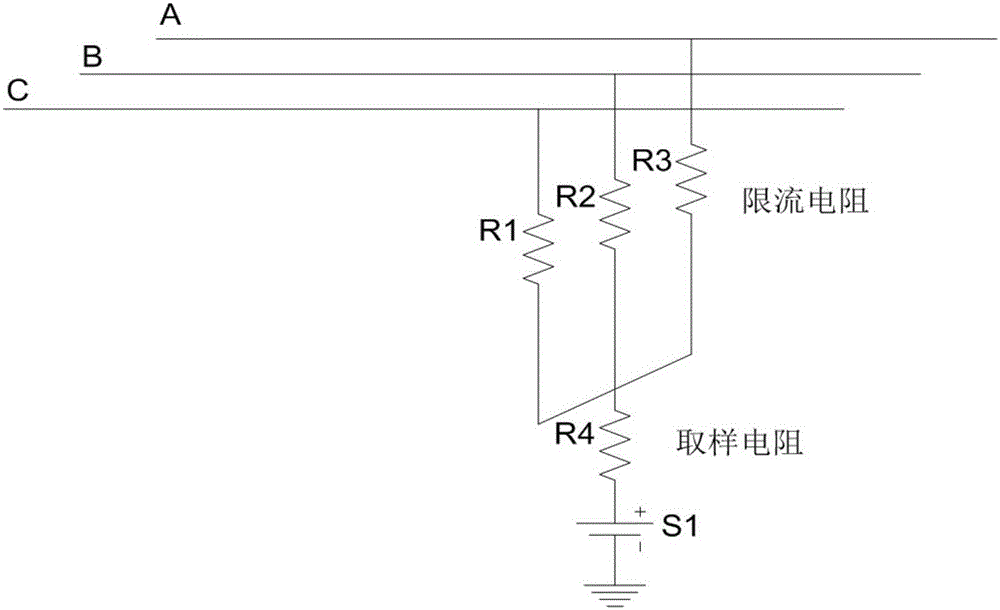

[0088] The global power cable insulation monitoring device has the following functions: measuring the global power cable insulation resistance R; equipment network and inter-network communication functions (in this example, zigbee wireless communication is used, and wireless communication such as wifi, bluetooth, etc. can also be used; 232, 485 and other wired communication methods); the switchgear status input is used to know whether the current feeder branch switchgear is put into use. The circuit topology of the internal CT power supply module of the global power cable ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com