Reference-electrode-supported nitrogen oxygen sensor and preparation method thereof

A technology of nitrogen and oxygen sensors and reference electrodes, which is applied to instruments, scientific instruments, and material analysis through electromagnetic means, can solve the problems of high manufacturing cost and unstable performance, reduce material types, increase response output voltage level, The effect of reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 - Fabrication of Sensor Ceramic Composite

[0050] 1. Porous (La 0.8 Sr 0.2 ) 0.95 MnO 3 (LSM) Fabrication of Support Layer Cast Film

[0051] Mix and ball-mill LSM powder, graphite pore-forming agent, solvent, and dispersant in proportion (1:0.2:0.4:0.05 mass ratio) for 24 hours, then add 9% LSM powder mass ratio binder, 6% LSM powder Additives such as plasticizers in proportion to body weight, continued ball milling for 12 hours. Vacuum defoaming for 15 minutes after the slurry is filtered, and then casting according to the required thickness to obtain a porous LSM support layer casting film green body;

[0052] 2. Preparation of dense 8mol% yttrium stabilized zirconia (8YSZ) electrolyte cast membrane

[0053] Mix and ball mill 8YSZ powder, solvent and dispersant in proportion (1:0.4:0.05 mass ratio) for 24 hours, then add 9% 8YSZ powder mass ratio binder and 6% 8YSZ powder mass ratio plasticizer Wait for the additive to continue ball milling for 12 h...

Embodiment 2

[0058] Example 2 - Fabrication of Sensors

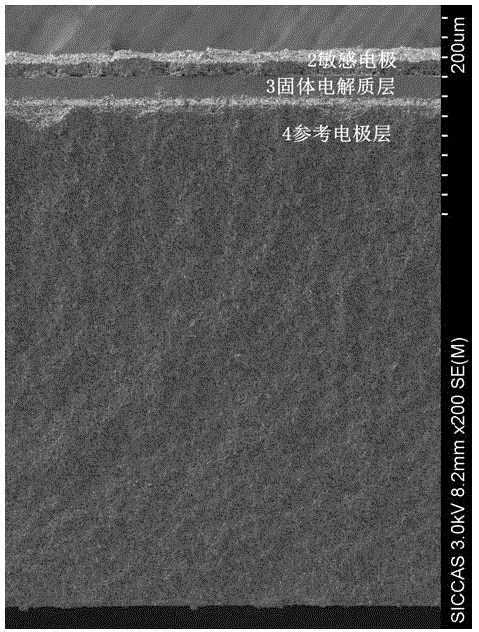

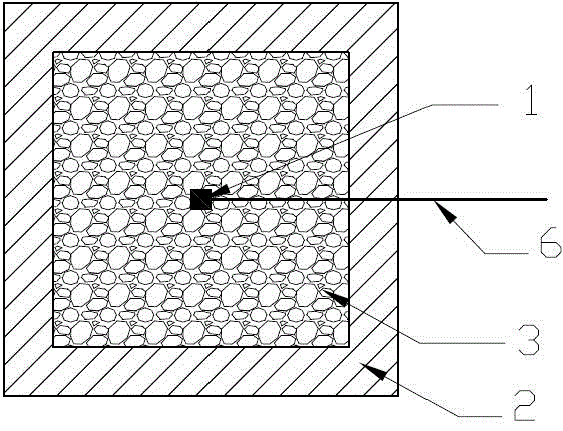

[0059] Such as Figure 2-4 As shown in the figure, positive (collector) electrode 1; sensitive electrode 2; electrolyte layer 3; reference electrode layer 4; negative (collector) electrode 5; wire 6; voltmeter 7. The present invention is a nitrogen and oxygen sensor with porous LSM as the reference electrode layer 4, porous LSM as the sensitive electrode layer 2, and 8YSZ as the electrolyte layer 3. It consists of the reference electrode layer 4, the electrolyte layer 3, the sensitive electrode layer 2, the positive ( The collector electrode 1, the negative (collector) electrode 5 and the wire 6 are composed, the electrolyte layer 3 is arranged on the upper surface of the reference electrode layer 4, the sensitive electrode layer 2 is arranged on the upper surface of the electrolyte layer 3, and the positive (collector) electrode 1 is arranged on the sensitive electrode 2 on the upper surface, the negative (collector) electrode 5 is...

Embodiment 3

[0061] Example 3 - Testing of Sensors

[0062] The working principle of the nitrogen-oxygen sensor of the present invention: the reference electrode layer 4, the electrolyte layer 3 and the sensitive electrode layer 2 constitute the sensitive layer of the nitrogen-oxygen sensor, and a wire 6 is passed between the positive (collector) electrode 1 and the negative (collector) electrode 5 A voltmeter 7 is connected in series; the pores of the porous LSM ceramic body constitute the channel for the diffusion of the measured gas, and the LSM has a positive effect on the NO in the measured atmosphere. 2 With the ability of catalytic decomposition, the measured atmosphere reacts in the process of diffusion in the pores of the LSM ceramic body 1 NO 2 is decomposed into NO and O 2 Thereby changing the concentration of oxygen ions on the interface of the LSM; the reference electrode layer 4 is a 0.2-1 mm ceramic body support layer, the diffusion channel is long, and the measured gas d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com