Self-adjustment type five-freedom-degree magnetic bearing

A technology of degree of freedom and magnetic bearing, which is applied in the field of non-contact support and hybrid magnetic bearing, can solve the problems of insufficient control of the degree of freedom of the radial suspension force of the rotor, large radial torsion of the rotor, and high power consumption, so as to achieve reliable suspension performance and reduce Effects of weight and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

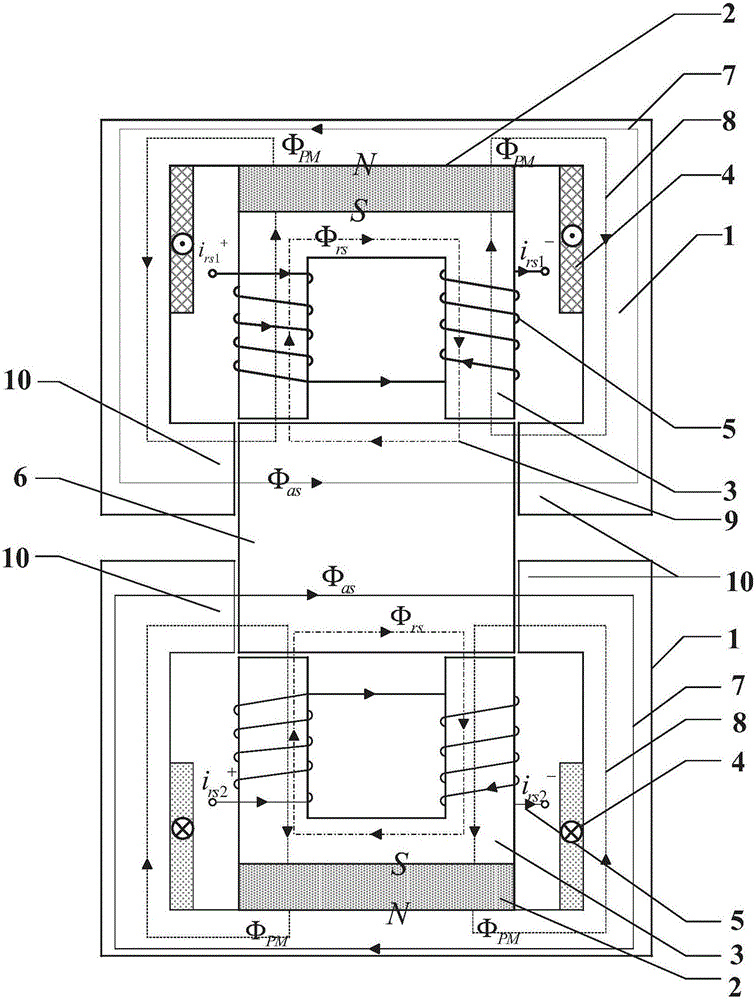

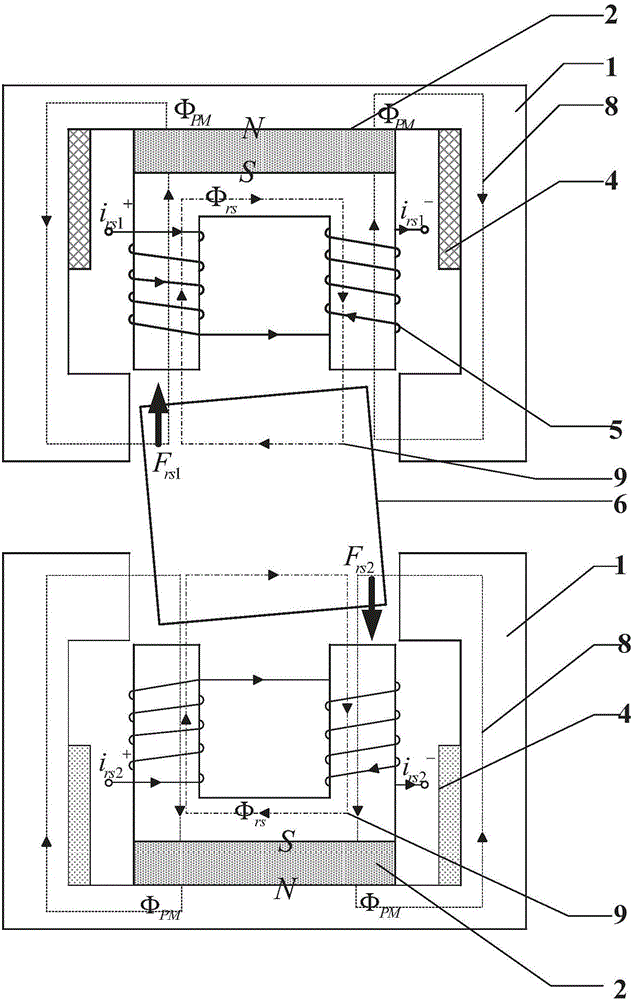

[0018] The present invention constructs a self-adjusting five-degree-of-freedom hybrid magnetic bearing, and constructs its mathematical model according to the equivalent magnetic circuit method. Based on this mathematical model combined with the predetermined design parameter index, the structural parameters and electrical parameters of the magnetic bearing are formulated and calculated, and a magnetic bearing with excellent performance and meeting the requirements of practical applications is designed according to this formula.

[0019] Based on these structural parameters, use the finite element analysis software Ansoft to further optimize the design of the magnetic bearing structural parameters, and verify the correctness of the structural design principles and magnetic flux distribution. Finally, according to the mathematical model and each actual parameter, design the controller circuit.

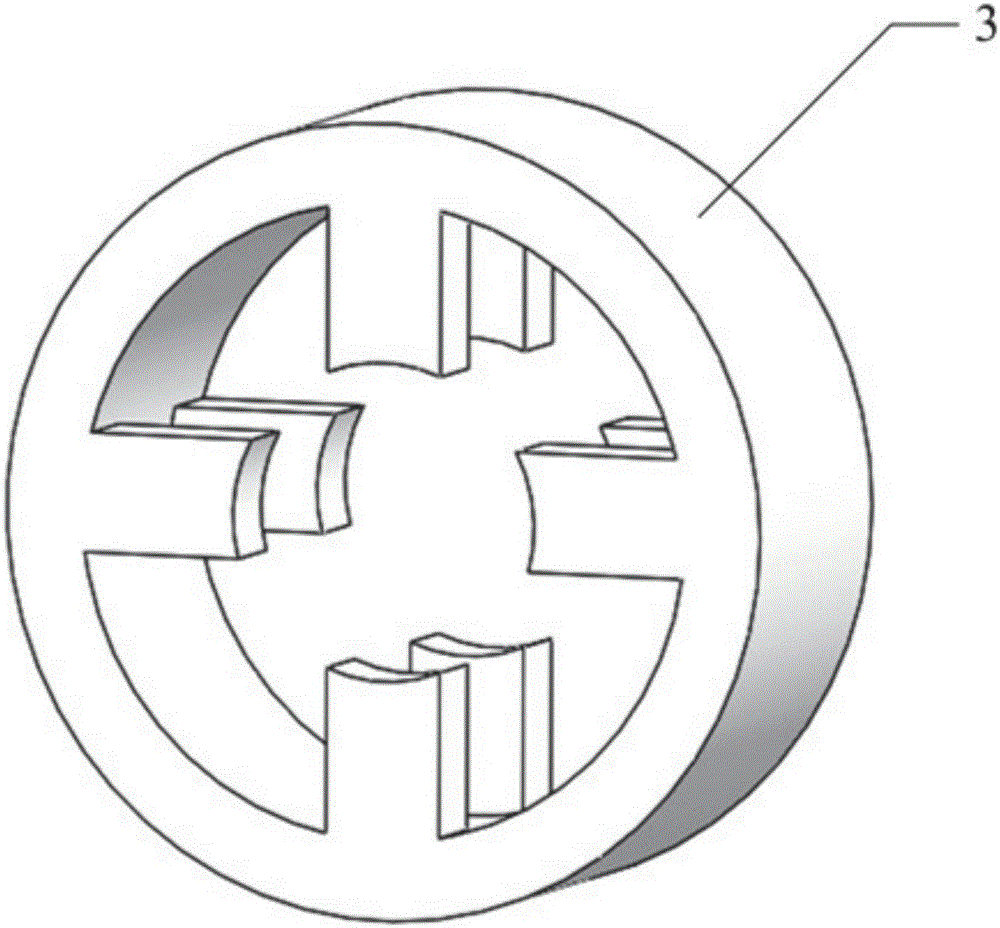

[0020] A self-adjusting five-degree-of-freedom magnetic bearing, comprising an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com