Special SPA circulating pump

A circulating pump and pump cover technology, which is applied to pumps, components of pumping devices for elastic fluids, pump devices, etc., can solve the problems of poor sealing, short service life, and noise of electric pumps in SPA circulating pumps, and achieve Solve the effect of mechanical seal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

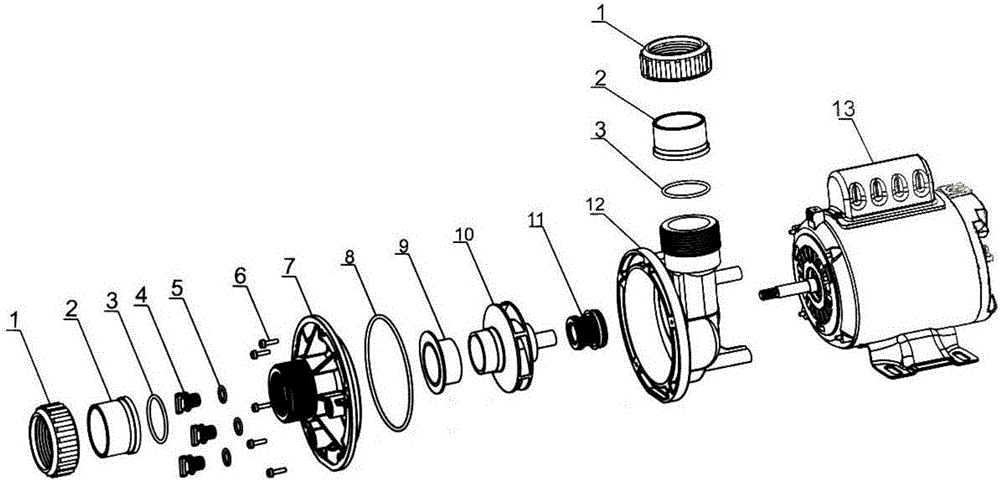

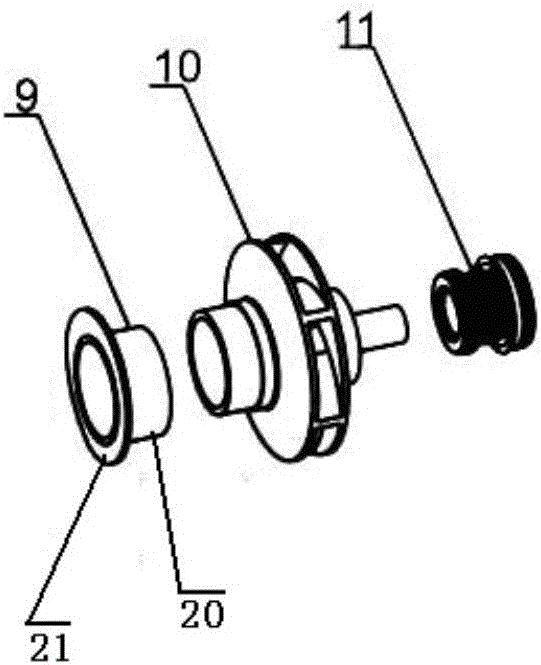

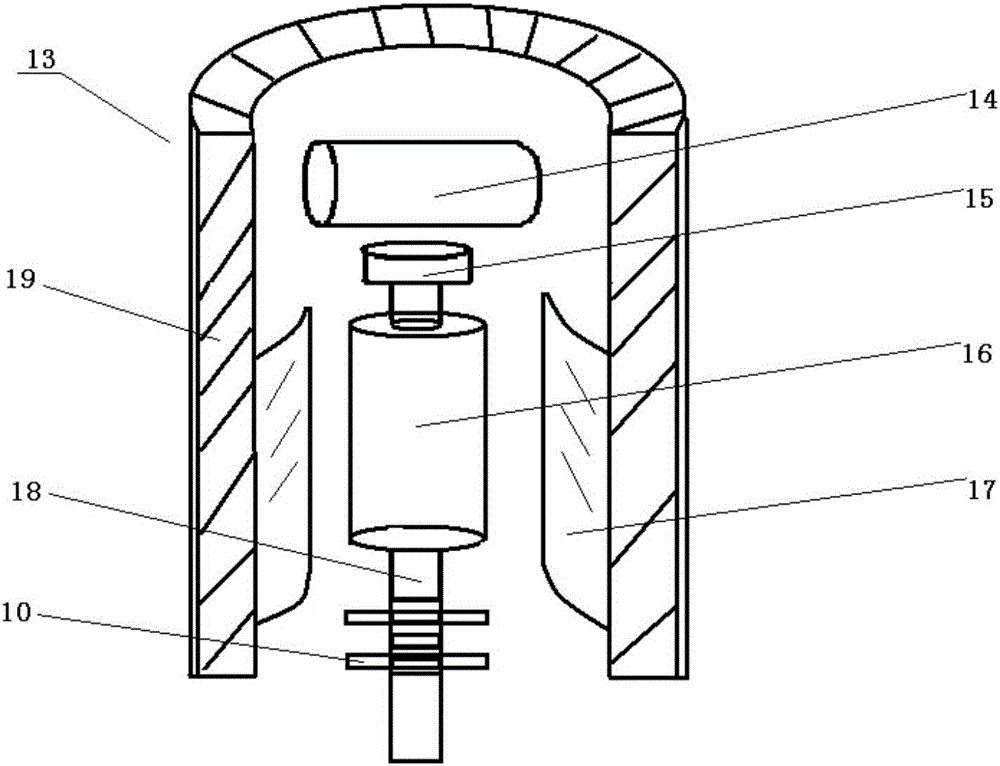

[0024] A circulating pump dedicated to SPA, including a pump casing assembly 12, an impeller 10, a bearing 18, a pump cover 7 and a motor 3, the impeller 10 is sleeved on the bearing 18 through a sleeve, and one side of the impeller 10 moves through the impeller The mouth cup 9 and the large O-ring 8 are in contact with the pump cover 7, and the other side is in contact with the pump casing assembly 12 through a non-mechanical viscous sleeve 11. The impeller movable mouth cup 9 includes a sleeve 20 and an end ring 21, so The outer diameter of the end ring 21 is 2-3 times the outer diameter of the sleeve 20, the sleeve 20 is sleeved on the outer wall of the shaft sleeve, and the end ring 21 is in interference fit with the inner hole of the pump cover 7, so The motor 13 includes a winding stator 17 and a rotor 16 in the motor casing 19, the two ends of the rotor 16 are respectively connected in series with the deep groove ball bearing head 15 and the impeller 10 through the beari...

Embodiment 2

[0026] A circulating pump dedicated to SPA, including a pump casing assembly 12, an impeller 10, a bearing 18, a pump cover 7 and a motor 3, the impeller 10 is sleeved on the bearing 18 through a sleeve, and one side of the impeller 10 moves through the impeller The mouth cup 9 and the large O-ring 8 are in contact with the pump cover 7, and the other side is in contact with the pump casing assembly 12 through a non-mechanical viscous sleeve 11. The impeller movable mouth cup 9 includes a sleeve 20 and an end ring 21, so The outer diameter of the end ring 21 is 2-3 times the outer diameter of the sleeve 20, the sleeve 20 is sleeved on the outer wall of the shaft sleeve, and the end ring 21 is in interference fit with the inner hole of the pump cover 7, so The motor 13 includes a winding stator 17 and a rotor 16 in the motor casing 19, the two ends of the rotor 16 are respectively connected in series with the deep groove ball bearing head 15 and the impeller 10 through the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com