Prefabricated Tunnel and Construction Method of Shield Tunnel Joint when Shield Tunneling Up and Down

A shield tunnel and tunnel technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as collapse, affecting the operation of existing tunnel trains, existing tunnel subsidence, etc. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

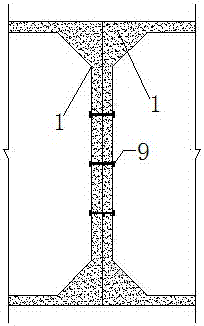

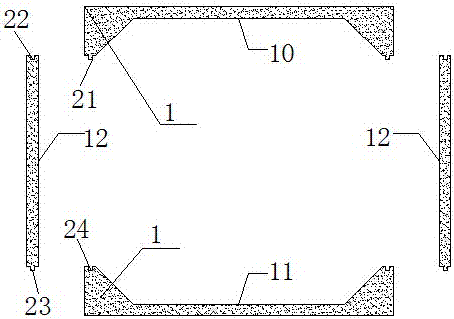

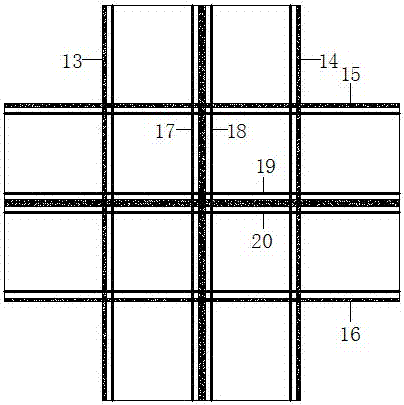

[0045] A prefabricated assembled tunnel with shield passing through shield nodes up and down, combining four shield tunnels passing up and down into one place, and the four shield tunnels are separate prefabricated tunnels, and the prefabricated tunnels include a roof 10, a bottom 11 and a top plate 10 and the bottom plate 11 are matched with the side wall 12 connected, and a chamfer 1 is provided at the joint between the top plate 10 and the side wall 12, and a chamfer 1 is provided at the joint between the bottom plate 11 and the side wall 12. Two tunnels at the same height are in The side walls are connected with bolts 9; bolt holes are reserved in the bottom plate 11 of the upper tunnel and the roof 10 of the lower tunnel, and the upper and lower tunnels are connected as a whole with bolts 9, that is, the prefabricated tunnel 13 on the left side of the upper layer and the right side of the upper layer The prefabricated tunnel 14; the prefabricated tunnel 15 on the left side...

Embodiment 2

[0051] A construction method for a prefabricated assembled tunnel at a shield node when a shield passes up and down, comprising the following steps:

[0052] (1) Fabrication of prefabricated tunnels outside the construction site

[0053] The prefabrication steps of the prefabricated tunnel are: making the formwork of the prefabricated tunnel, binding the steel cage, reserving bolt holes on the side walls of the prefabricated tunnel where bolts need to be connected, and reserving bolts on the prefabricated tunnel floor above and the prefabricated tunnel roof below. Holes, pouring concrete, curing, removing formwork;

[0054] (2) Foundation pit excavation and support

[0055] (1) Excavate the foundation pit to the design depth of the prefabricated tunnel floor below, and carry out foundation pit side slope support;

[0056] (2) The bottom of the pit is compacted or grouted within 3-5 meters below the bottom of the pit to reinforce the bottom of the pit;

[0057] (3) Prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com