A degradable drill-free bridge plug

A bridge plug and cone technology, applied to degradable drill-free bridge plugs. It can solve the problems of large time consumption, increased cost and difficulty, and achieve the effect of large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

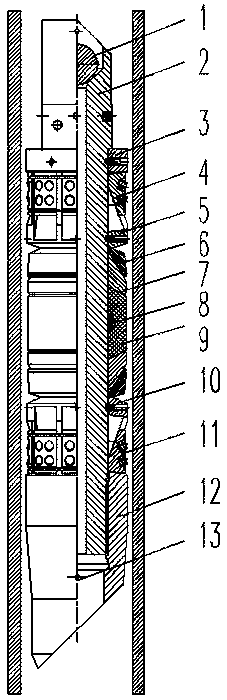

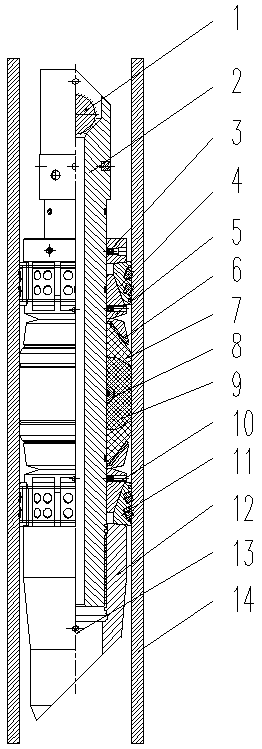

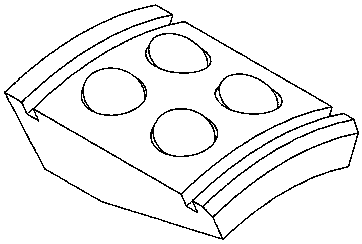

[0020] This embodiment provides a degradable drill-free bridge plug, such as figure 1 and figure 2 As shown, it includes central tube 2, guide shoe 12, slip assembly, lower cone 10, inner and outer backing ring assembly 6, end rubber cylinder 7, middle rubber cylinder 9, upper cone 5, slip stop ring 3 and The fracturing ball 1, the lower end of the central tube 2 is provided with a trapezoidal thread, which is connected with the guide shoe 12 through a trapezoidal thread and bonded with thread glue. The middle rubber cylinder 9 has two symmetrical end rubber cylinders 7 and inner and outer backing rings. The assembly 6 protects, the inner and outer back ring assembly 6 is in contact with the upper cone 5 and the lower cone 10, and the tapered side of the upper cone 5 and the lower cone 10 is placed in the middle of the tapered surface formed by the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com