Equal ball and same diameter fracturing sleeve, single ball fracturing sleeve and equal ball and same diameter fracturing string

A technology for fracturing sliding sleeves and fracturing balls, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of multi-stage reconstruction of oil layers, improve fracturing effect and reduce the risk of sand sticking , Improve the effect of layered transformation series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Among them, the use of adjective or adverbial modifiers "horizontal" and "vertical", "upward" and "downward" is only for the convenience of relative reference between groups of terms, and does not describe the meaning of the modified terms. any specific orientation constraints.

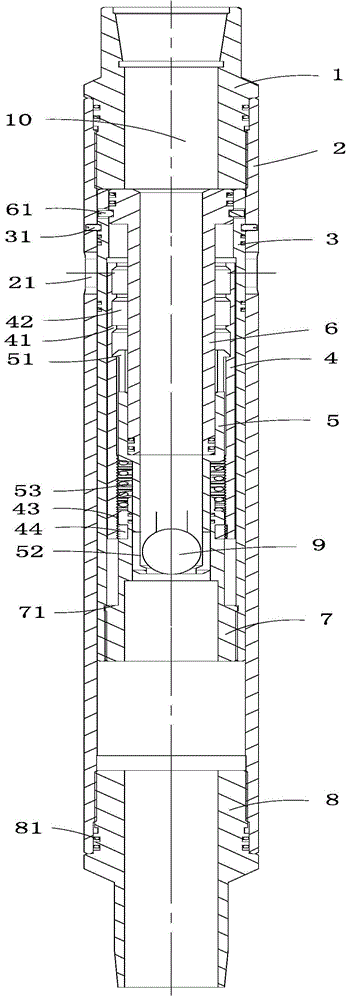

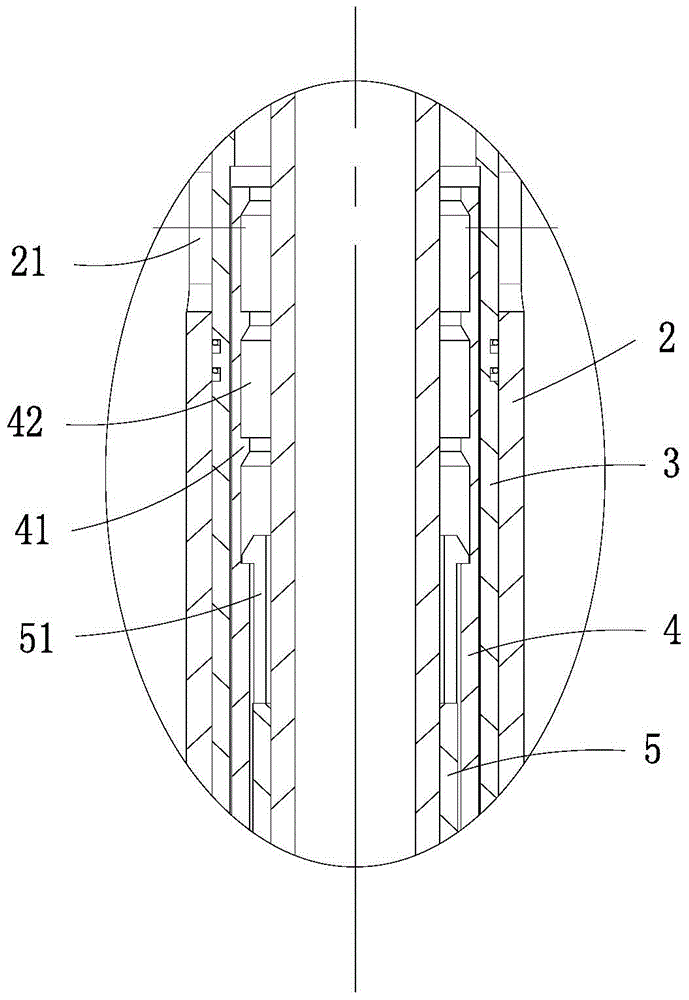

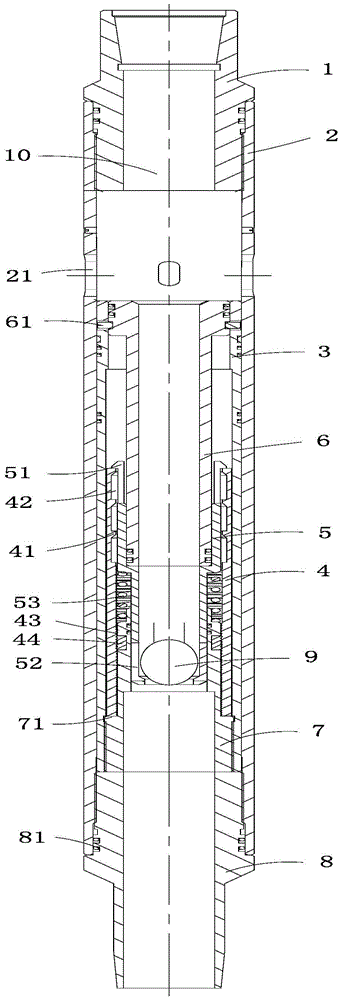

[0051] Such as figure 1 , figure 2 As shown, the present invention provides an equal-spherical and same-diameter fracturing sliding sleeve, which includes an upper joint 1 , an inner sliding sleeve 3 , a counting rod 4 and a sliding cylinder 5 . Wherein, the lower end of the upper joint 1 is connected with the outer cylinder 2, and the upper end of the outer cylinder 2 is provided with an internal and external connecting passage 21 passing through the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com