Magnetically induced shape memory alloy confined friction damper with self-resetting function

A friction damper and memory alloy technology, which is applied to bridge parts, building components, bridges, etc., to achieve stable performance, large recoverable deformation, and strong damping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

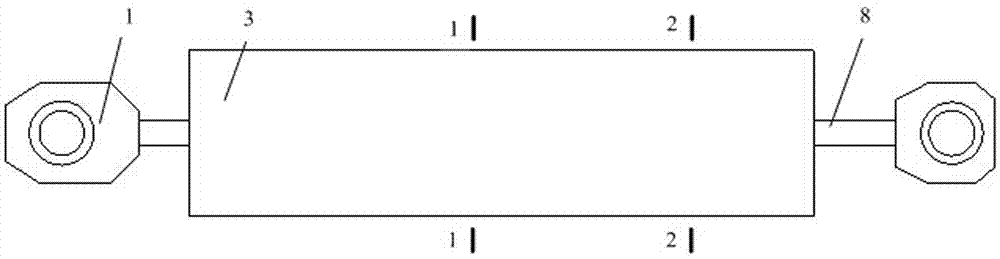

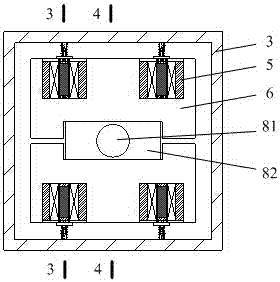

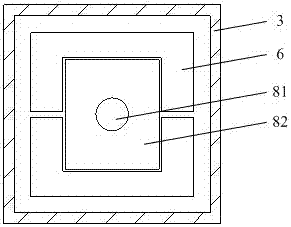

[0022] refer to Figure 1-Figure 5 As shown, the magnetically induced shape memory alloy constrained friction damper with self-resetting function includes connecting flange 1, connecting nut 2, cylinder barrel 3, middle guide nut 4, control unit 5, outer slider 6, and closed guide nut 7 , the core guide rod 8, the connecting flange 1 is arranged at both ends of the damper, the connecting flange 1 at one end is connected to the connecting nut 2, and the connecting flange 1 at the other end is connected to the The core guide rod 8 is connected, the connecting nut 2 is installed at the end of one side of the cavity of the cylinder barrel 3, the core guide rod 8 is arranged inside the cylinder barrel 3, and the outside of the core guide rod 8 is wrapped with Referring to the outer slider 6 , several control units 5 are provided on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com