Flame-retardant plant fiber and flame-retardant paper

A technology of plant fiber and flame retardant paper, applied in the field of flame retardant materials, can solve problems such as poor flame retardant effect and loss of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

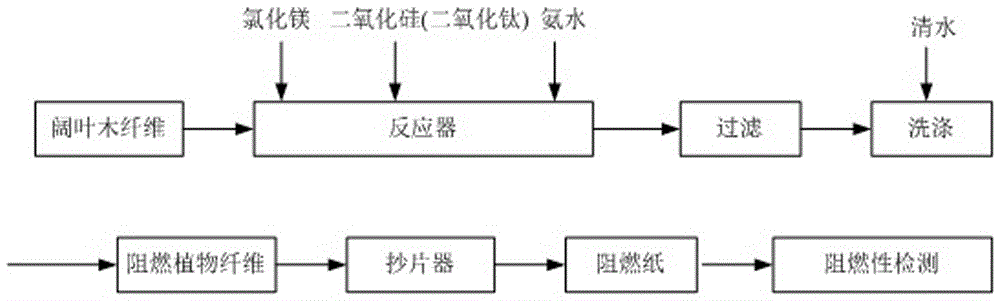

[0020] Embodiment 1: A kind of flame-retardant plant fiber, is prepared by the following method:

[0021] ①Add 100mL of magnesium chloride solution with a concentration of 0.8mol / L to a three-necked flask, heat and stir, control the temperature at 50°C, add 3g of hardwood fiber and 0.04g of ultrafine silica, and stir rapidly for 20min;

[0022] ② Add 200mL of ammonia water with a concentration of 2%, and continue to stir rapidly for 10min;

[0023] ③ After filtering the broad-leaved wood fibers, wash them with clean water to obtain flame-retardant plant fibers;

[0024] ④Copy the flame-retardant plant fiber with a copying machine and make it quantitatively 45g. m -2 flame retardant paper.

Embodiment 2

[0025] Embodiment 2: A kind of flame-retardant plant fiber, is prepared by the following method:

[0026] ①Add 100mL of magnesium chloride solution with a concentration of 1.0mol / L into a three-neck flask, heat and stir, control the temperature at 60°C, add 3g of hardwood fiber and 0.06g of ultrafine silica, and stir rapidly for 30min;

[0027] ② Add 200mL of ammonia water with a concentration of 2%, and continue to stir rapidly for 15min;

[0028] ③ After filtering the broad-leaved wood fibers, wash them with clean water to obtain flame-retardant plant fibers;

[0029] ④Copy the flame-retardant plant fiber with a copying machine and make it quantitatively 50g. m -2 flame retardant paper.

Embodiment 3

[0030] Embodiment 3: A kind of flame-retardant plant fiber, is prepared by the following method:

[0031] ①Add 100mL of magnesium chloride solution with a concentration of 1.2mol / L to a three-neck flask, heat and stir, control the temperature at 70°C, add 3g of hardwood fiber and 0.04g of ultrafine silica, and stir rapidly for 30min;

[0032] ② Add 200mL of ammonia water with a concentration of 2.5%, and continue to stir rapidly for 20min;

[0033] ③ After filtering the broad-leaved wood fibers, wash them with clean water to obtain flame-retardant plant fibers;

[0034] ④Copy the flame-retardant plant fiber with a sheeter to make a quantitative 60g. m -2 flame retardant paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com