A kind of purple pigment paste for internal coloring of cultural pulp containing chemical mechanical pulp and preparation method thereof

A purple pigment and chemical-mechanical technology, applied in the field of paper-making pigment paste, can solve the problems of incomplete lake reaction of basic dyes and deep dyeing, and achieve outstanding commercial value, small particle size and high storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

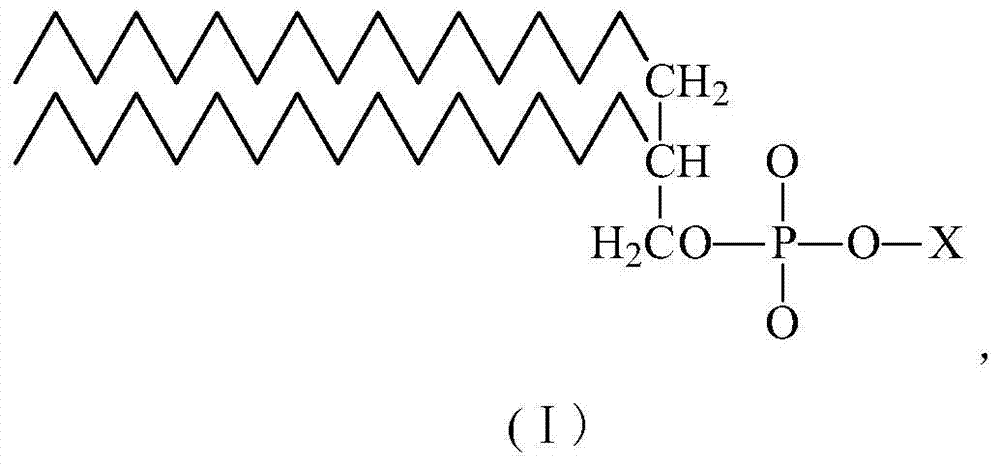

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, 22 parts of lightfast grades are 2 grades of green lotus lake pigments, 6 parts of alkyl phosphate ester salts, 3 parts of fatty alcohol block copolymers, 2.2 parts of structural formula (II) compounds, 11 parts of ethylene glycol, 0.1 part of benzothiazolinone bactericide, 0.2 part of mineral oil defoamer, and deionized water make up to a total weight of 100 parts.

Embodiment 2

[0028] Embodiment 2, 22 parts of light fastness grades are the Qinglian lake pigment of grade 1, 6 parts of alkyl phosphate ester salts, 3 parts of fatty alcohol block copolymers, 2.2 parts of structural formula (II) compounds, 11 parts of propylene glycol, 0.1 parts Isothiazolinone bactericide, 0.2 part of mineral oil defoamer, and deionized water make up to 100 parts by total weight.

Embodiment 3

[0029] Example 3, 20 parts of Qinglian lake pigments with a light fastness grade of grade 1, 5.4 parts of alkylsulfonate ester salts, 2.7 parts of isomeric alcohol polyoxyethylene ethers, 2 parts of structural formula (Ⅲ) compounds, 10 parts of propylene glycol, 0.1 part of benzothiazolinone bactericide, 0.2 part of mineral oil defoamer, and deionized water make up to a total weight of 100 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com