Intelligent magnetic transfer device

A transfer device and intelligent technology, applied in the direction of transportation and packaging, non-mechanical conveyors, conveyors, etc., can solve problems such as loss, workpiece slipping, collision, etc., and achieve the effect of quality assurance and reducing the probability of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

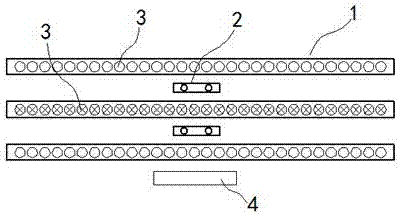

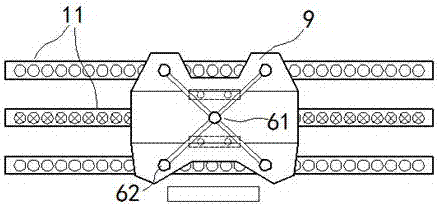

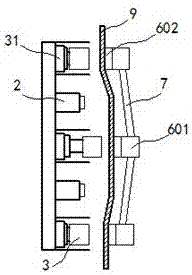

[0016] exist Figure 1 to Figure 4 In the shown embodiment, the intelligent magnetic transfer device includes a mechanical arm, a transmission track 1 and a processing machine tool 2; the transmission track 1 includes three guide rails 11 arranged in parallel, equidistant on each guide rail 11 Electromagnetic columns 3 are arranged, and the magnetic pole direction of each electromagnetic column 3 is perpendicular to the track surface of the transmission track 1; each of the electromagnetic columns 3 is electrically connected to the controller 4; when each electromagnetic column 3 is turned on, the middle one The magnetic pole direction of each electromagnetic column 3 on the guide rail 11 is opposite to the magnetic pole direction of the electromagnetic column 3 on the guide rail 11 on both sides; a lifting platform 31 is installed below each described electromagnetic column 3, and each described lifting platform 31 is coupled with the controller 4 The processing machine tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com