Liquid storage tank capable of preventing liquid from sloshing

A liquid storage tank and liquid-proof technology, which is applied in packaging, large containers, transportation and packaging, etc., can solve problems such as poor anti-wave effects, and achieve the effects of improving driving safety, sufficient connection area, and high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

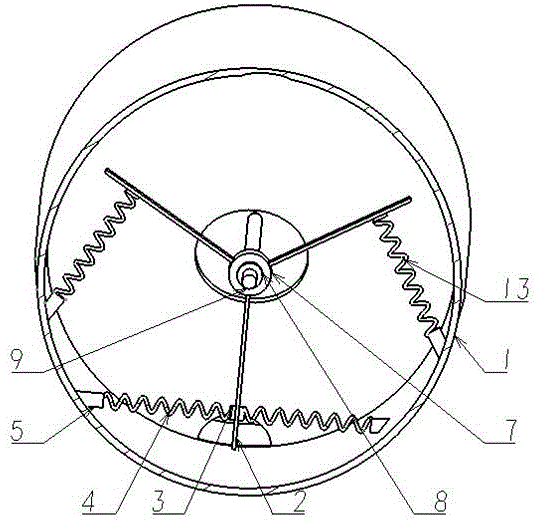

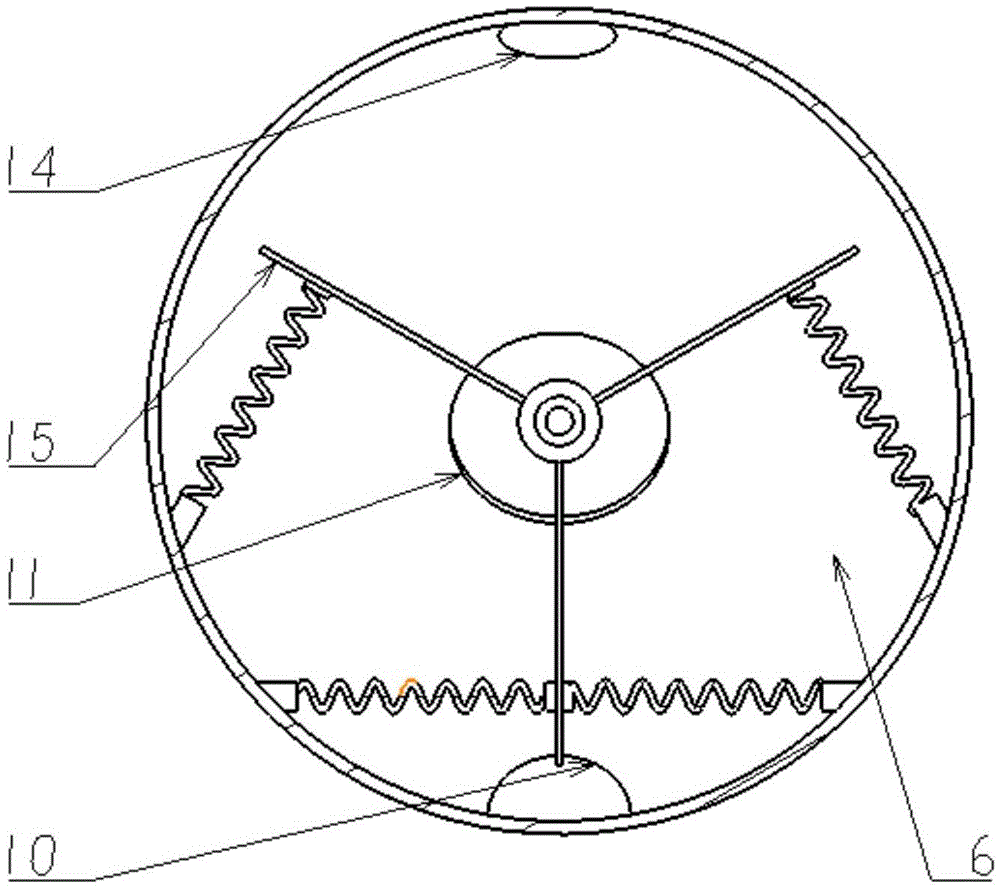

[0031] A liquid storage tank for preventing liquid sloshing according to the present invention includes a main body, two heads 12 with the same structure, a longitudinal axis 9, n wave-proof plates 6 with the same structure, and n+1 sets of blade anti-wave plates with the same structure. Wave device, wherein: n is a natural number greater than or equal to 1.

[0032] The anti-wave plate 6 is an elliptical flat plate structure, and the center of the anti-wave plate 6 is provided with a manhole 11 for the anti-wave plate, which allows the longitudinal axis 9 to pass through and be inserted, and is convenient for cleaning, inspection and maintenance; The top of the board 6 in the direction of the long axis is provided with a through hole 14 on the top of the anti-wave board to ensure that when loading and unloading liquid cargo, the air can communicate with the outside through ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com