Ultrasonic and electric heating compounding anti-icing and deicing device

An ultrasonic and electric heating technology, which is applied in the fields of deicing and aircraft anti-icing, can solve the problems of inaccessibility, achieve the effects of energy reduction, heat loss reduction, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

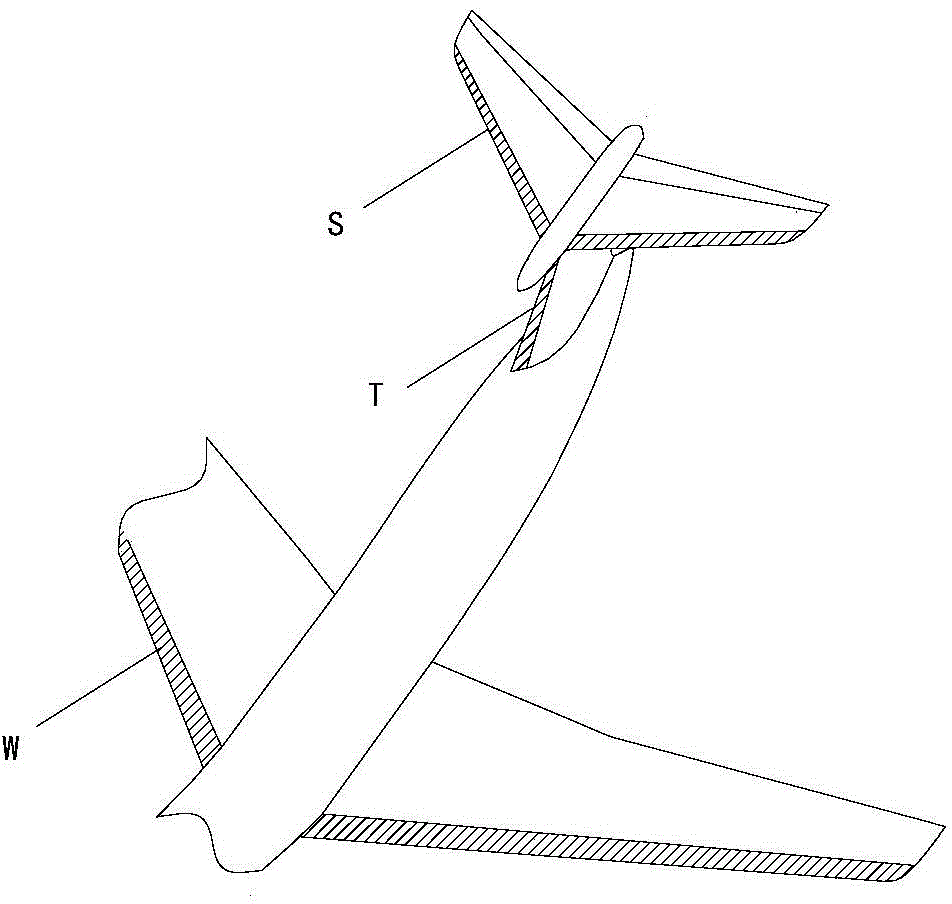

[0026] The present invention will be further described below. see figure 1 , for existing aircraft, the anti-icing position generally needs to include the leading edge of the wing and the leading edge of the empennage.

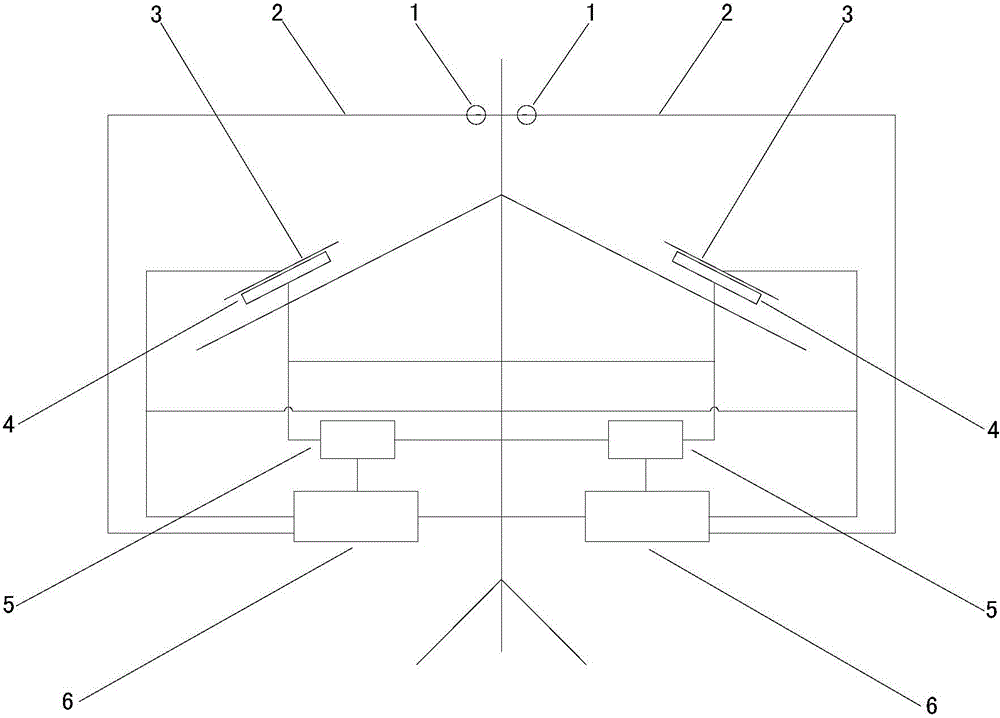

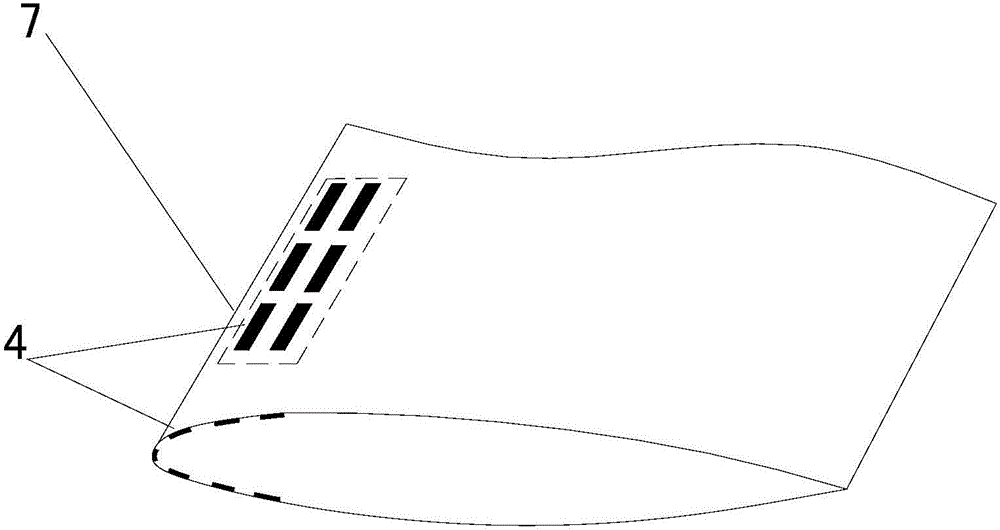

[0027] An ultrasonic and electric heating composite anti-icing device, such as figure 2 shown, including:

[0028] Icing signal device 1, electric heating assembly 3, ultrasonic oscillator 4, ultrasonic controller 5, anti-icing control box 6;

[0029] The icing signal device 1 is used to detect whether the aircraft has entered the icing area, and if it enters the icing area, an icing warning signal and icing rate information are sent to the anti-icing control box 6 through the signal line 2;

[0030] The anti-icing control box 6 is used to send a pulse heating signal to the electric heating component 3 first according to the icing alarm signal and the icing rate information, and then send the start work command to the ultrasonic controller 5;

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com