Composite structure bulletproof armor capable of resisting machine gun ammunition penetration and manufacturing method thereof

A composite structure and bulletproof technology, which is applied in the direction of protective equipment, chemical instruments and methods, clothing, etc., can solve problems such as fragmentation, insufficient hardness and stiffness of high-performance fiber composite materials, and inability to resist continuous projectile damage. Avoid the effect of large deformation and strong destructive force of bulletproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

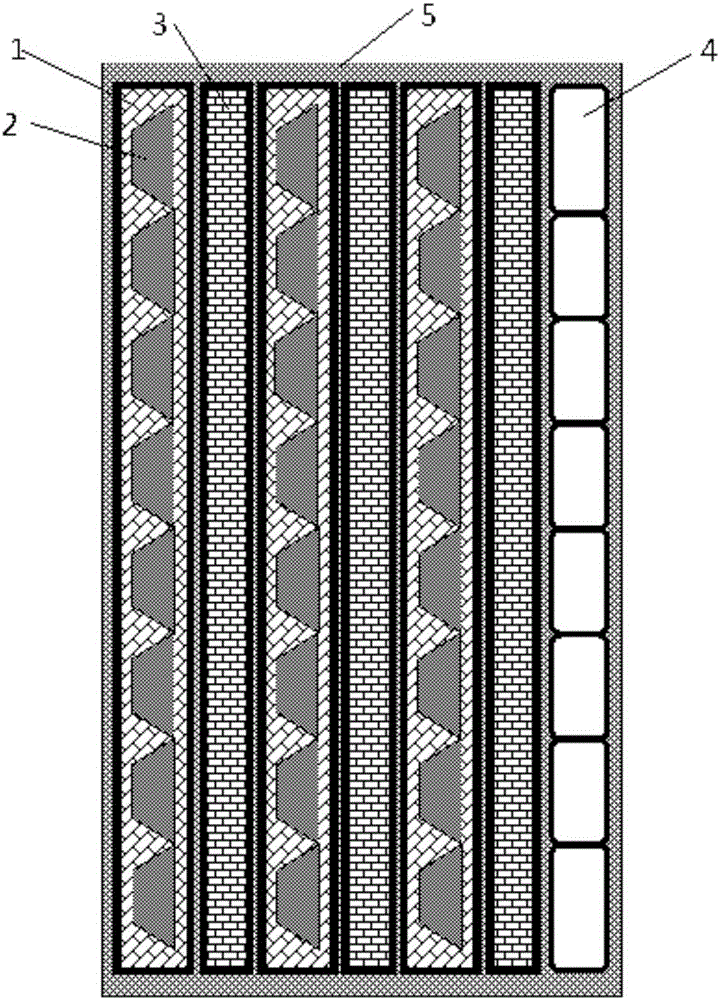

[0040] A composite bulletproof armor for resisting the penetration of machine gun bullets is composed of four parts: a three-dimensional braided rigid spliced protective plate layer, a three-dimensional braided flexible protective plate layer, a spliced buffer layer and a carbon fiber three-dimensional braided overall frame.

[0041] First, the preparation of the three-dimensional braided rigid splicing protective plate layer: using silicon carbide as the three-dimensional three-dimensional fabric reinforcing fiber filament, three-dimensional multi-directional reinforced fabric prefabricated body is prepared in three-dimensional four-way form, and silicon carbide ceramics are embedded in the prefabricated body preparation process Conical frustum circular ceramic splicing pieces made of materials, after the preparation of the three-dimensional multi-directional reinforced fabric prefabricated body, the ceramic matrix and the three-dimensional multi-directional reinforced fabr...

Embodiment 2

[0046] A composite bulletproof armor for resisting the penetration of machine gun bullets is composed of four parts: a three-dimensional braided rigid spliced protective plate layer, a three-dimensional braided flexible protective plate layer, a spliced buffer layer and a carbon fiber three-dimensional braided overall frame.

[0047] First, the preparation of three-dimensional braided rigid spliced fender plies. Using boron carbide as a three-dimensional fabric reinforcing fiber filament, a three-dimensional multi-directional reinforced fabric prefabricated body is prepared in a three-dimensional six-directional weaving form, and a conical frustum circular ceramic splicing piece made of silicon carbide ceramic is embedded in the prefabricated body preparation process. After the preparation of the three-dimensional multi-directional reinforced fabric prefabricated body, the ceramic matrix and the three-dimensional multi-directional reinforced fabric prefabricated body are ...

Embodiment 3

[0052] A composite bulletproof armor for resisting the penetration of machine gun bullets is composed of four parts: a three-dimensional braided rigid spliced protective plate layer, a three-dimensional braided flexible protective plate layer, a spliced buffer layer and a carbon fiber three-dimensional braided overall frame.

[0053] First, the preparation of three-dimensional braided rigid spliced fender plies. Boron carbide is used as the three-dimensional fabric reinforcing fiber filament, and the three-dimensional multi-directional reinforced fabric prefabricated body is prepared in the form of three-dimensional four-way weaving. During the preparation process of the prefabricated body, a frustum-shaped ceramic splicing piece made of alumina ceramic is embedded. After the preparation of the three-dimensional multi-directional reinforced fabric prefabricated body, the ceramic matrix and the three-dimensional multi-directional reinforced fabric prefabricated body are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com