Mechanical two-jaw synchronous clamp structure

A kind of machinery and fixture technology, which is applied in the field of mechanical two-jaw synchronous fixture structure, can solve the problems of not being able to supply workpieces of different shapes, demanding installation space, and poor practicability, and achieve high work efficiency, safe and reliable work, and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

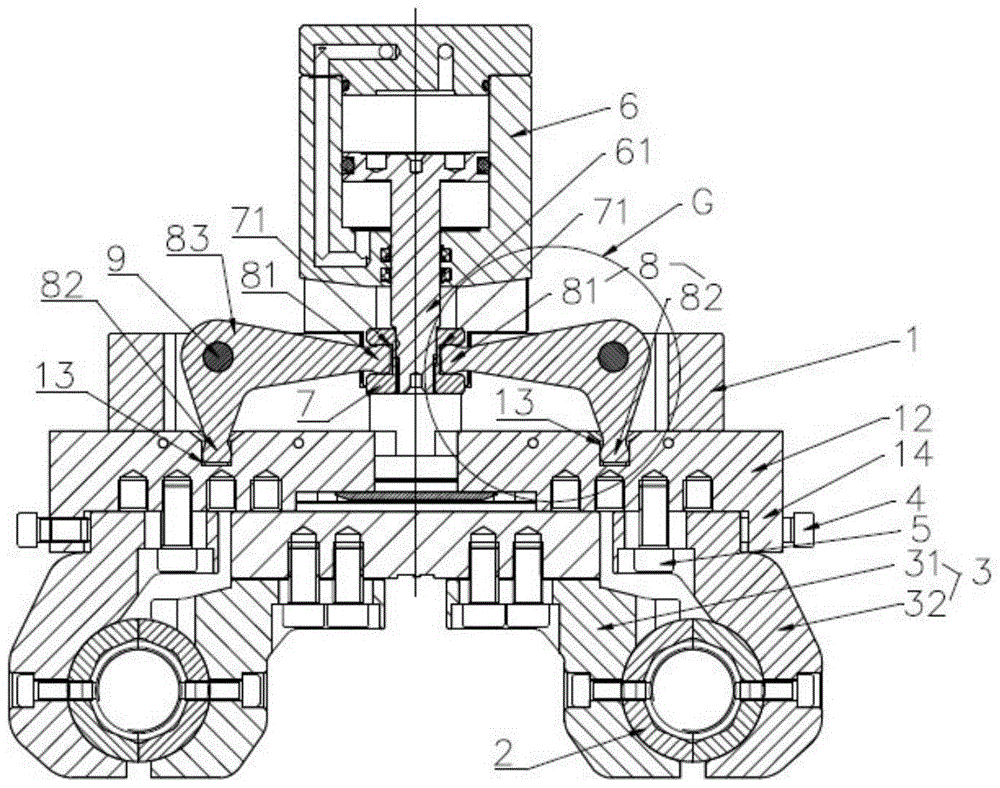

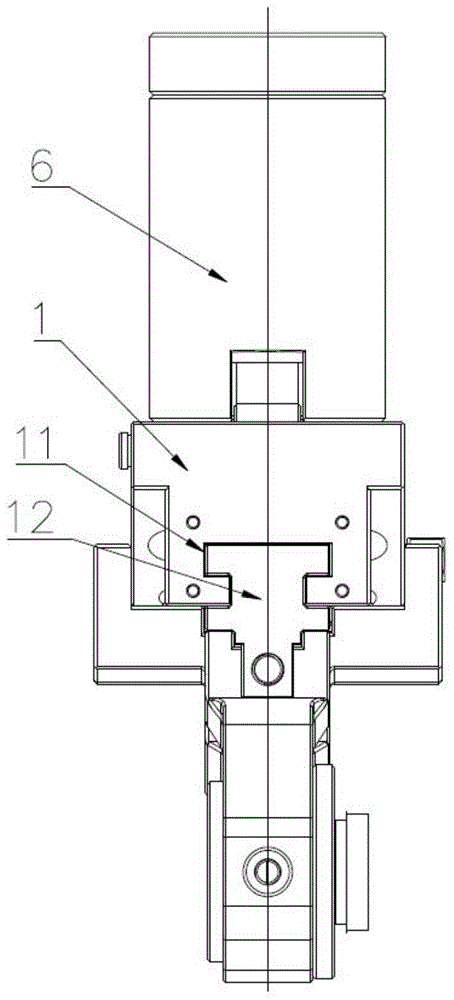

[0023] see Figure 1-Figure 3 As shown, a mechanical two-jaw synchronous fixture structure includes a base 1, a workpiece holder 2 and two pairs of fixtures 3, each pair of fixtures 3 includes a fixed jaw 31 and a movable jaw 32, and the workpiece holder 2 The inner end surfaces of the fixed claws 31 and the movable claws 32 are fixed by screws; the two fixed claws 31 are fixedly arranged on the middle end of the base 1, and the two movable claws 32 are respectively movably arranged on the left end and the left end of the base 1. The right end, and the rear ends of the two movable claws 32 are connected with the same driving device through respective "┐"-shaped connecting rods 8 .

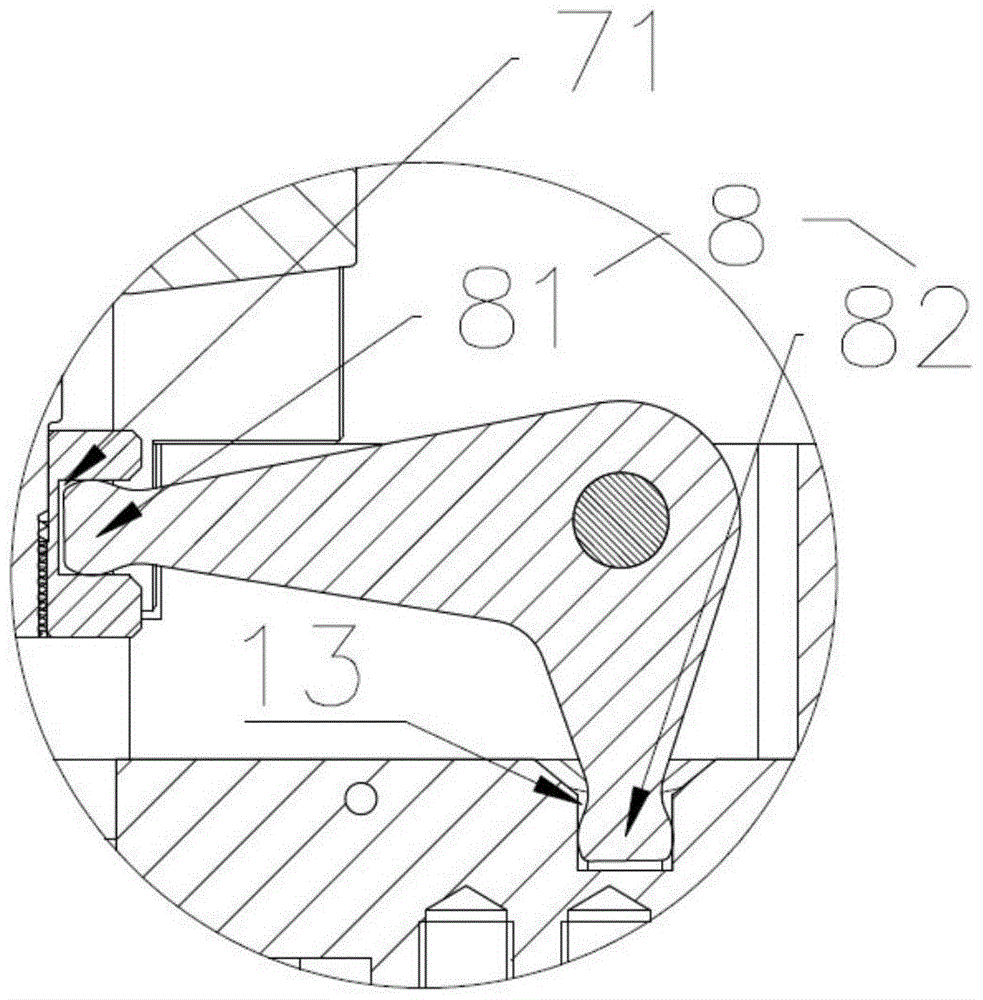

[0024] As a first option, the "┐"-shaped connecting rod 8 has a connecting rod driving end 81 and a connecting rod driven end 82, the connecting rod driven end 82 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com