Device and method for mounting plunger pump

A plunger pump and plunger rod technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor sealing effect of plunger pumps, uneven force on plunger rods, and reduced service life. Effects of reduced oil leakage, easy operation, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

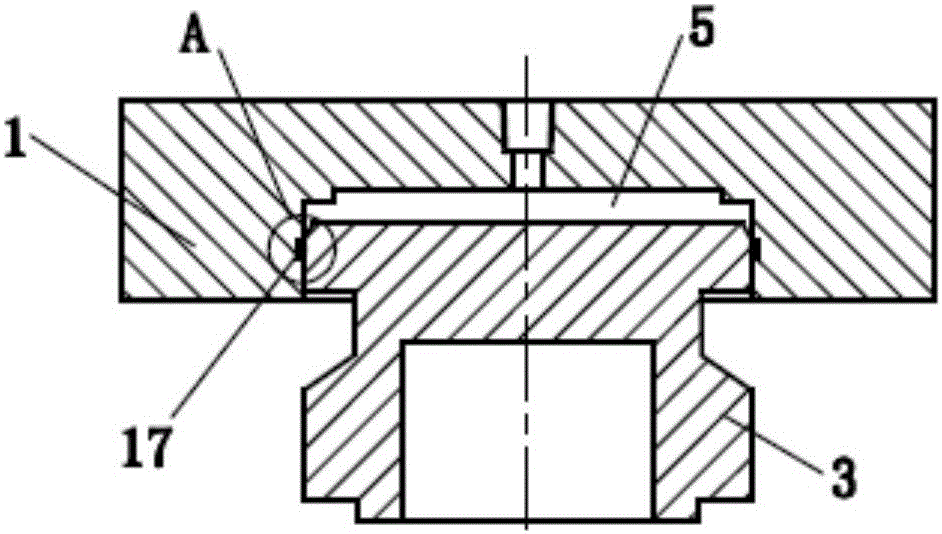

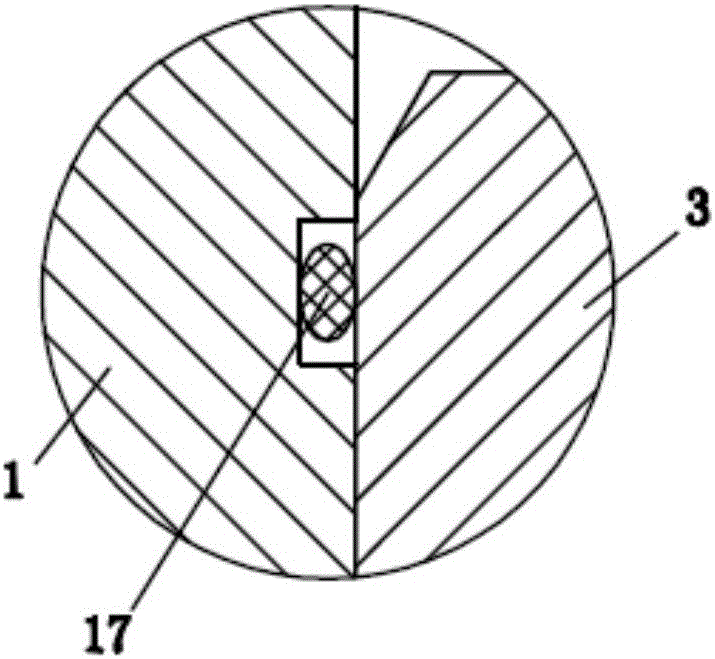

[0039] The specific embodiment of the present invention is as Figures 1 to 8 shown. A device for installing a plunger pump includes a double force cylinder 1; a pressing piston 3 is arranged on the double force cylinder 1; the pressing piston 3 is a piston driven by oil pressure.

[0040] A cavity 5 is provided on the double force cylinder 1 , and one end of the compression piston 3 is located in the cavity 5 . An annular groove is provided on the side wall of the cavity 5, and a sealing ring 17 is installed on the groove. The sealing ring 17 is an O-ring. The sealing ring 17 is located between the compression piston 3 and the cavity 5, and plays a role in preventing the oil in the cavity 5 from leaking from the gap between the two.

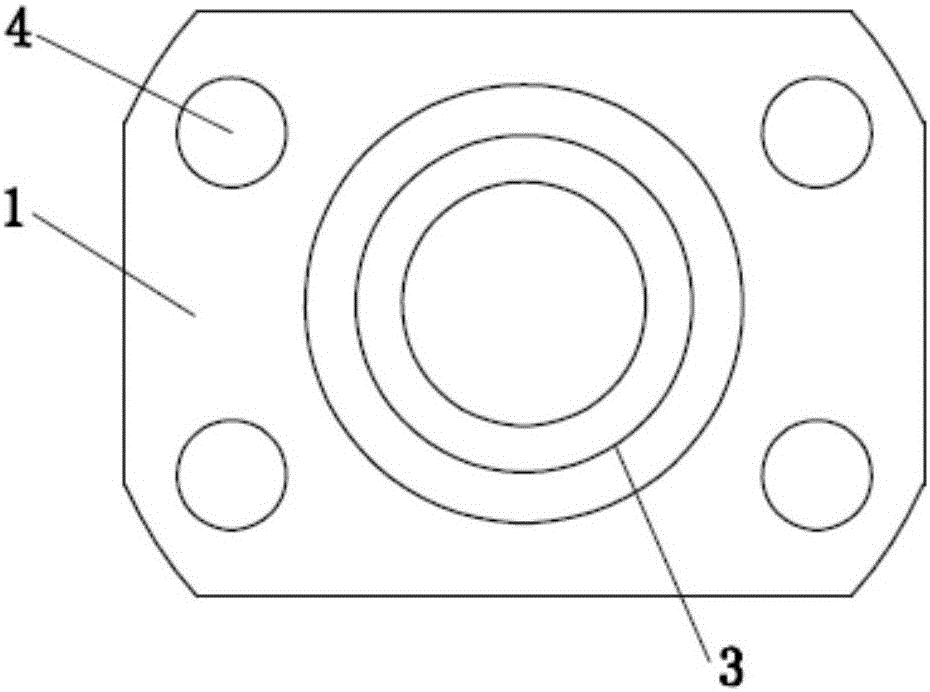

[0041] A positioning hole 4 is respectively provided at the four corners of the edge of the double power cylinder 1 . The positioning hole 4 can allow the double power cylinder 1 to be set on the four end cap screws 6 of the plunger pump. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com