Segmented jaw for reducing machine

A shrinking machine and jaw technology, applied in workpiece clamping devices, metal processing equipment, feeding devices, etc., can solve the problems of affecting the positioning accuracy of parts, affecting the processing accuracy, time-consuming and labor-intensive, etc., to reduce maintenance costs, The effect of improving work efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

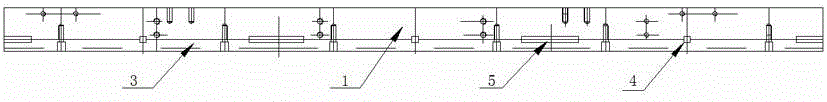

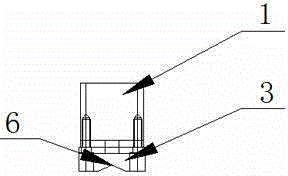

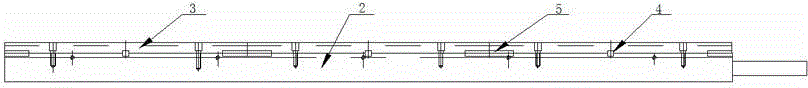

[0012] Such as figure 1 , figure 2 , image 3 The segmented jaws for the reducing machine of the present invention include an upper jaw body 1 and a lower jaw body 2, and the jaws of the upper jaw body 1 and the lower jaw body 2 are respectively spliced by three inserts 3, The middle part of each insert 3 is provided with a transverse keyway 4, and each insert 3 is respectively connected and positioned with the upper tong body 1 and the lower tong body 2 through the transverse keyway 4 and the flat key, and the two ends of each insert 2 are respectively There is a longitudinal keyway 5, and the two ends of each insert 3 are respectively connected and positioned with the upper tong body 1 and the lower tong body 2 through the longitudinal keyway 5 and the flat key; the inserts 3 are fixed on the upper tong body by hexagon socket screws 1 and the lower clamp body 2; the outer surface of the insert 3 is provided with a V-shaped groove 6 along the length direction.

[0013] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com