Batch preparation method of porous carbon nitride material under assistance of organic carboxylic acid

A technology of organic carboxylic acid and carbon nitride, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of complicated experimental steps and easy pollution of hard template method, and achieve improved mass transfer and diffusion process, Improve the degradation ability and promote the effect of rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

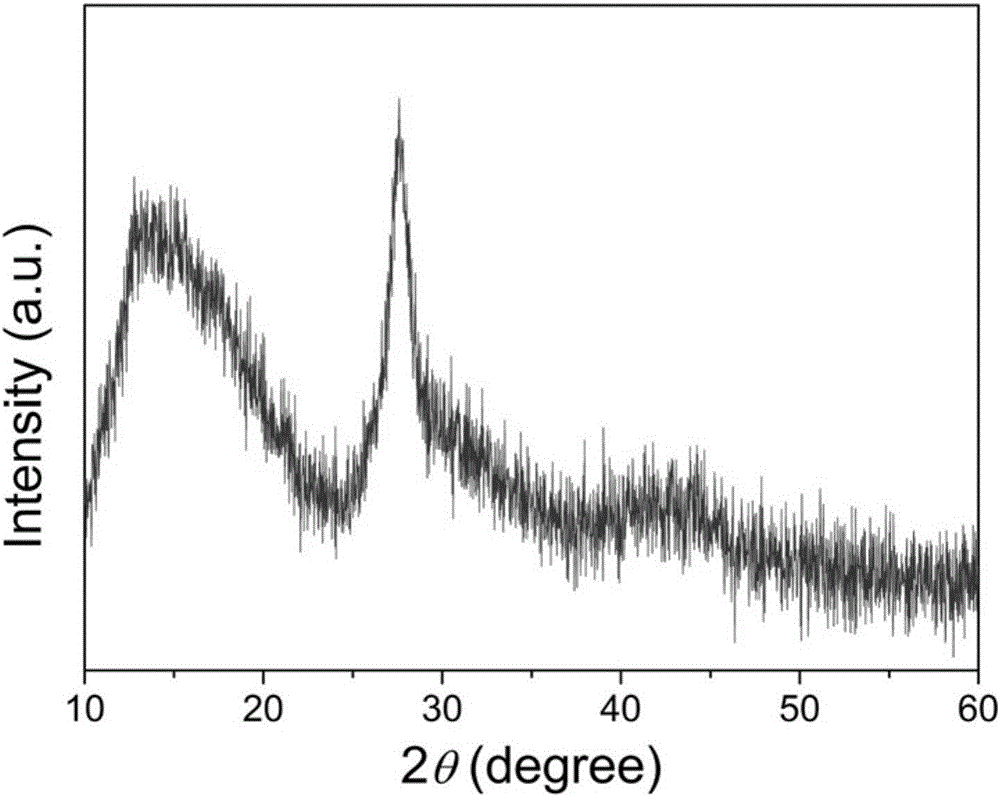

Embodiment 1

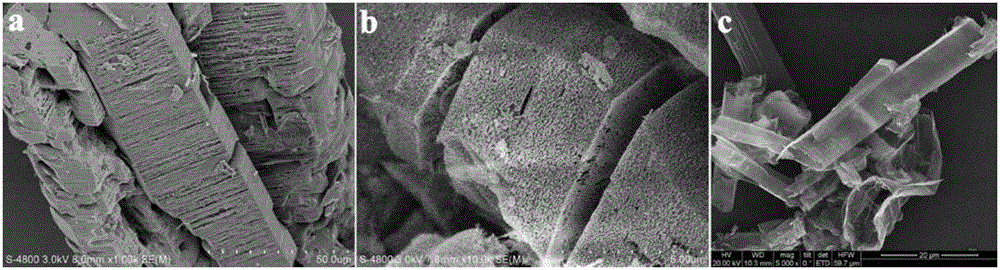

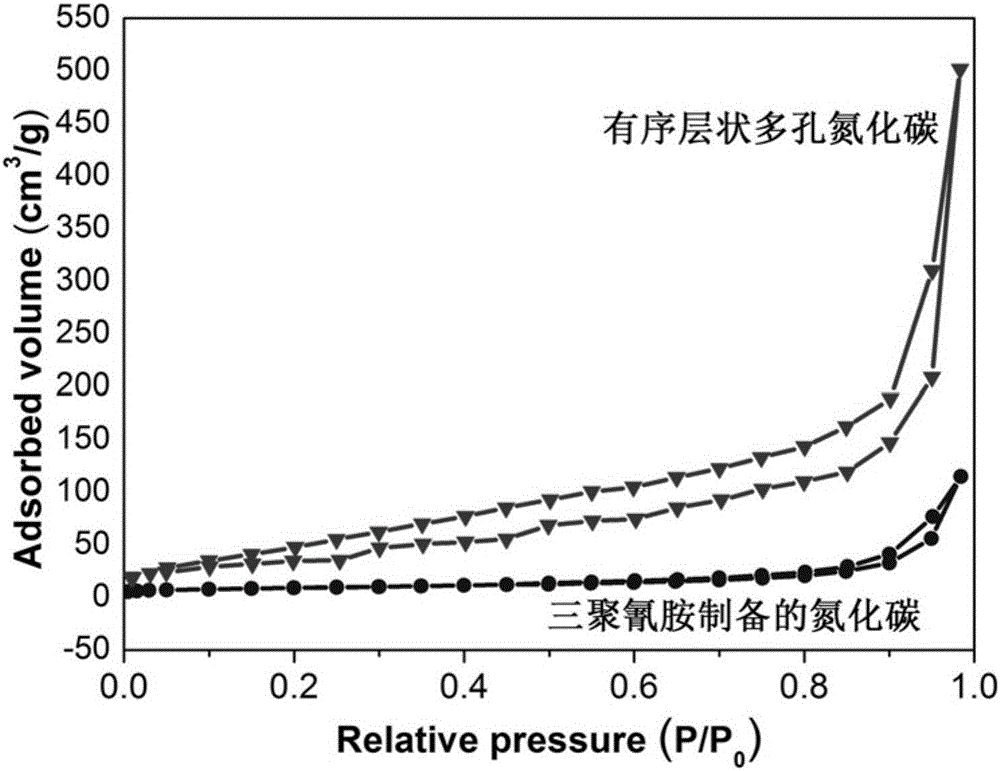

[0024] Mix melamine and analytically pure acetic acid in a mass ratio of 1:10, and disperse them in solvent water, wherein the volume ratio of water and acetic acid is 1:1. Carbonized hydrothermal precursor; the above hydrothermal precursor was calcined at 550 °C for 2 h under nitrogen protection in a tube furnace to obtain an ordered layered porous carbon nitride material, such as figure 1 , figure 2 a shown. The specific surface area of the ordered layered porous carbon nitride material is 138 m 2 g -1 , much higher than the specific surface area of carbon nitride materials prepared by pure melamine of 31m 2 / g, as in image 3 shown.

Embodiment 2

[0026] Mix melamine and acetic acid at a mass ratio of 1:10, and under anhydrous conditions, heat the above solution in a hydrothermal reactor at 180 °C for 16 h to obtain a porous carbon nitride hydrothermal precursor; calcined at 500 °C for 6 h under the protection of inert gas in a furnace to obtain porous carbon nitride materials, such as figure 2 b shown. The specific surface area of the uniform porous carbon nitride material is 76m 2 / g.

Embodiment 3

[0028] Mix melamine and oxalic acid in a mass ratio of 1:5, and disperse them in solvent water, wherein the mass ratio of water and oxalic acid is 1:1, and heat the above solution in a hydrothermal reactor at 180 ° C for 5 hours to obtain porous carbon nitride water. Thermal precursor; the above-mentioned hydrothermal precursor is calcined at 600° C. for 2 hours under the protection of inert gas in a tube furnace to obtain a porous carbon nitride material. The specific surface area of the porous carbon nitride material is 106m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com