Coix seed instant slices and processing method thereof

A processing method and technology of instant food tablets, applied in the field of coix coix instant food tablets and its processing, can solve the problems of lack of chewiness, poor taste, poor rehydration, etc., and achieve improved rehydration uniformity, short drying time, and moist taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A processing method for Coix instant food tablets, comprising the steps of:

[0037] 1) Cleaning and soaking

[0038] Take 10 kg of coix seed washed with clean water, add 50 kg of 0.1% sodium bicarbonate aqueous solution, soak for 1 hour, then rinse the soaked coix seed twice with clean water, drain, and send it into a double-roll extruder Squeeze and crush, the distance between the two rollers is 2mm, and the coix seed is crushed into 4-6 petals.

[0039] 2) Second soaking

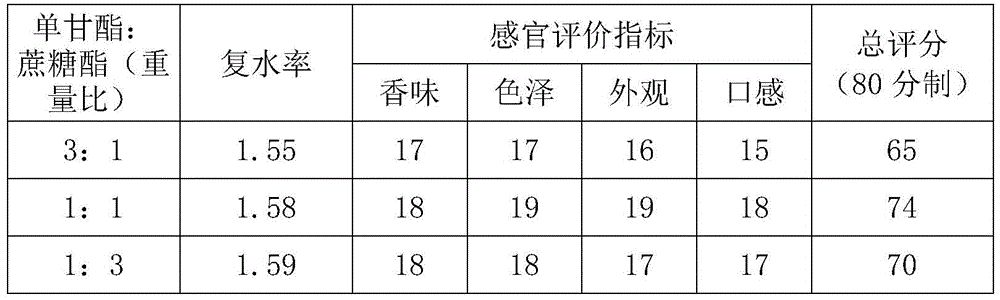

[0040] Add 2 times the weight of clear water to the broken coix seed grains, and then add 0.2% of the weight of the coix seed grains. The compound emulsifier is formed by mixing monoglyceride and sucrose ester in a weight ratio of 3:1. Soak for 2 hours, stir and turn the material 1 to 2 times during the soaking process, so that the coix seed grains can fully absorb the water containing the compound emulsifier, and the swollen coix seed grains are obtained.

[0041] 3) Cooking

[0042] After dra...

Embodiment 2

[0048] A processing method for Coix instant food tablets, comprising the steps of:

[0049] 1) Cleaning and soaking

[0050] Take 50 kg of coix seed washed with clean water, add 200 kg of sodium bicarbonate aqueous solution with a mass concentration of 0.3%, soak for 1.5 hours, then rinse the soaked coix seed with clean water for 3 times, drain, and send it into a double-roll extruder Squeeze and crush, the distance between the two rollers is 3mm, and the coix seed is crushed into 4-6 petals.

[0051] 2) Second soaking

[0052] Add 2.5 times the weight of clear water to the broken coix seed grains, and then add 0.4% of the coix seed grain weight compound emulsifier, which is formed by mixing monoglyceride and sucrose ester in a weight ratio of 1:1, Soak for 3 hours, stir and turn the material 1-2 times during the soaking process, so that the coix seed grains can fully absorb the water containing the compound emulsifier, and the swollen coix seed grains are obtained.

[0053...

Embodiment 3

[0060] A processing method for Coix instant food tablets, comprising the steps of:

[0061] 1) Cleaning and soaking

[0062] Take 100 kg of coix seed washed with clean water, add 300 kg of 0.5% sodium bicarbonate aqueous solution, soak for 2 hours, then rinse the soaked coix seed with clean water for 3 times, drain, and send it into a double-roll extruder Squeeze and crush, the distance between the two rollers is 4mm, and the coix seed is crushed into 4-6 petals.

[0063] 2) Second soaking

[0064] Add 3 times the weight of clear water to the broken coix seed grains, and then add 0.6% of the weight of the coix seed grains. The compound emulsifier is formed by mixing monoglyceride and sucrose ester in a weight ratio of 1:3. Soak for 4 hours, stir and turn the material 1 to 2 times during the soaking process, so that the coix seed grains can fully absorb the water containing the compound emulsifier, and the swollen coix seed grains are obtained.

[0065] 3) Cooking

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com