Triticale fine dried noodles and making method thereof

A production method and wheat technology, applied in the field of food processing, can solve the problems of destroying triticale, affecting ingredients, affecting the taste of noodles, lack of elasticity of noodles, etc., and achieving the effects of reasonable compatibility ratio, good elasticity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

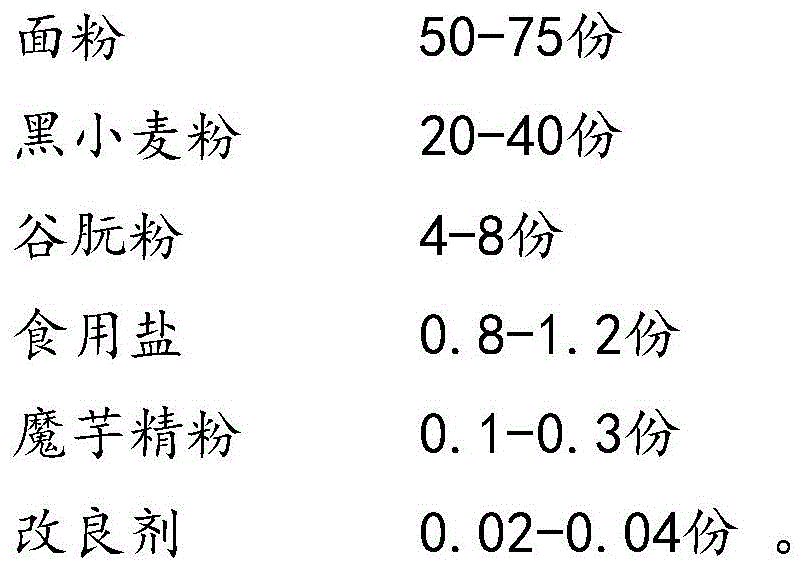

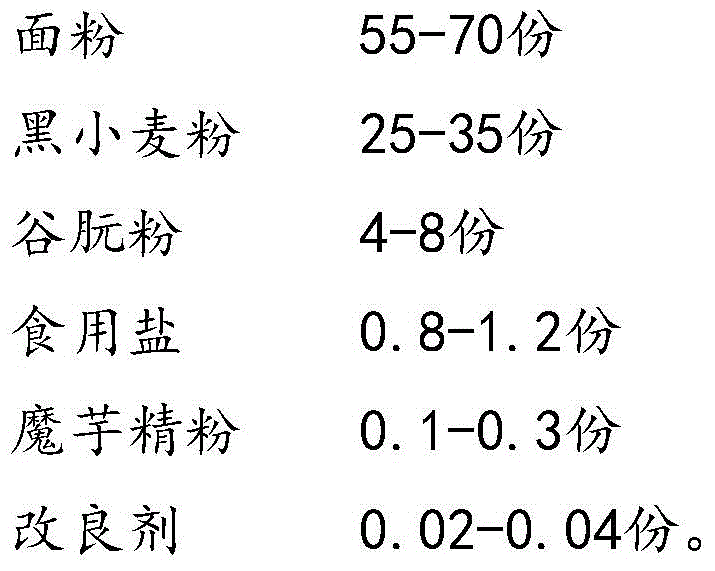

[0032] A kind of black wheat vermicelli, comprises the raw material of following ratio by weight:

[0033] Flour: 75

[0034] Triticale flour: 20

[0035] Gluten: 4

[0036] Edible salt: 0.8

[0037] Konjac flour: 0.1

[0038] Improver: 0.02.

[0039] The preparation method of above-mentioned black wheat vermicelli, comprises the following steps:

[0040] a. Soak konjac powder in appropriate amount of water 2 hours in advance, wait until it is completely dissolved, and set aside;

[0041] B, flour, triticale flour, gluten powder are placed in the blender and mix evenly;

[0042] c. Mix edible salt and improver into step a and mix evenly, set aside;

[0043] d. Add the uniformly mixed solution in step c to step b, add a certain amount of water to knead the dough, and the kneading time is about 13 minutes;

[0044] E, put the dough reconciled in step d into a ripening machine for ripening, and set aside;

[0045] f. Carrying out rolling, cutting, drying, cutting, weighi...

Embodiment 2

[0047] A kind of black wheat vermicelli, comprises the raw material of following ratio by weight:

[0048] Flour: 63

[0049] Triticale flour: 30

[0050] Gluten: 6

[0051] Edible salt: 1.0

[0052] Konjac powder: 0.2

[0053] Improver: 0.03.

[0054] The preparation method of above-mentioned black wheat vermicelli, comprises the following steps:

[0055] a. Soak konjac powder in appropriate amount of water 2 hours in advance, wait until it is completely dissolved, and set aside;

[0056] B, flour, triticale flour, gluten powder are placed in the blender and mix evenly;

[0057] c. Mix edible salt and improver into step a and mix evenly, set aside;

[0058] d. Add the uniformly mixed solution in step c to step b, add a certain amount of water to knead the dough, and the kneading time is about 18 minutes;

[0059] E, put the dough reconciled in step d into a ripening machine for ripening, and set aside;

[0060] f. Carrying out rolling, cutting, drying, cutting, weigh...

Embodiment 3

[0062] A kind of black wheat vermicelli, comprises the raw material of following ratio by weight:

[0063] Flour: 50

[0064] Triticale flour: 40

[0065] Gluten: 8

[0066] Edible salt: 1.2

[0067] Konjac powder: 0.3

[0068] Improver: 0.04.

[0069] The preparation method of above-mentioned black wheat vermicelli, comprises the following steps:

[0070] a. Soak konjac powder in appropriate amount of water 2 hours in advance, wait until it is completely dissolved, and set aside;

[0071] B, flour, triticale flour, gluten powder are placed in the blender and mix evenly;

[0072] c. Mix edible salt and improver into step a and mix evenly, set aside;

[0073] d. Add the uniformly mixed solution in step c to step b, add a certain amount of water to knead the dough, and the kneading time is about 15 minutes;

[0074] E, put the dough reconciled in step d into a ripening machine for ripening, and set aside;

[0075] f. Carrying out rolling, cutting, drying, cutting, weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com