Method for simultaneously reducing production of acrylamide and 5-hydroxymethylfurfural in high-temperature processed foods

A technology of hydroxymethylfurfural and high-temperature processing, which is applied in food ingredients, food forming, food ingredients as emulsifiers, etc. It can solve the problem of not being able to meet the pursuit of food umami taste, adding a large amount of sodium chloride, affecting food quality, etc. problems, to achieve the effect of inhibiting the formation of acrylamide and 5-hydroxymethylfurfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

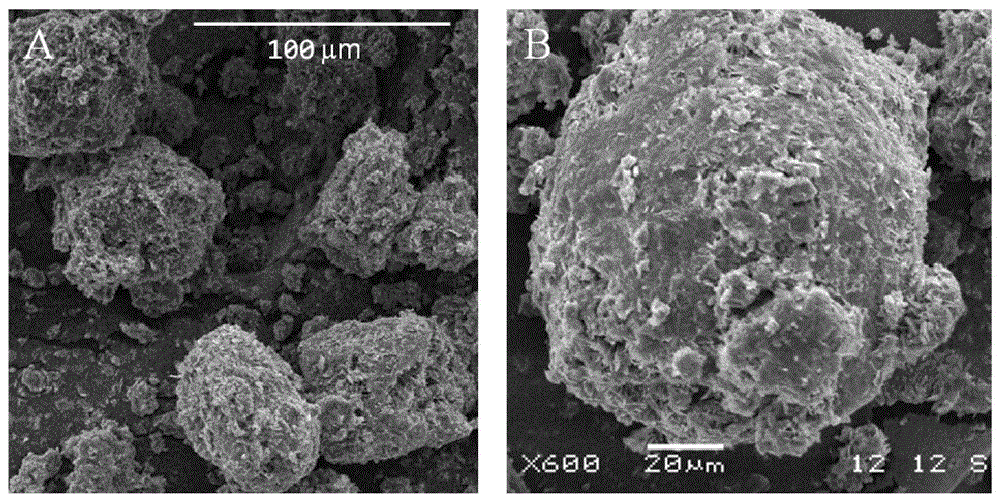

[0021] Using sodium glutamate as the core material, palm wax as the wall material, and glycerol monostearate as the emulsifier, make sodium glutamate microcapsules; take the particle size uniformity and sustained release effect of sodium glutamate microcapsules as the benchmark To measure the quality of microcapsules, add sodium glutamate microcapsules instead of sodium glutamate to biscuit making under high temperature conditions.

[0022] The specific operation process is as follows:

[0023] 1. Making microcapsules of sodium glutamate: weigh 2 parts of sodium glutamate, 4 parts of palm wax, and 1 part of glyceryl monostearate in parts by weight, add 200 parts of ultrapure water and heat to dissolve. Use a high-speed shear emulsifier in a water bath to emulsify at a speed of 19000rpm / min for 30min to make the mixed solution into a uniform emulsion. Spray-drying was carried out under the following conditions to prepare sodium glutamate microcapsules.

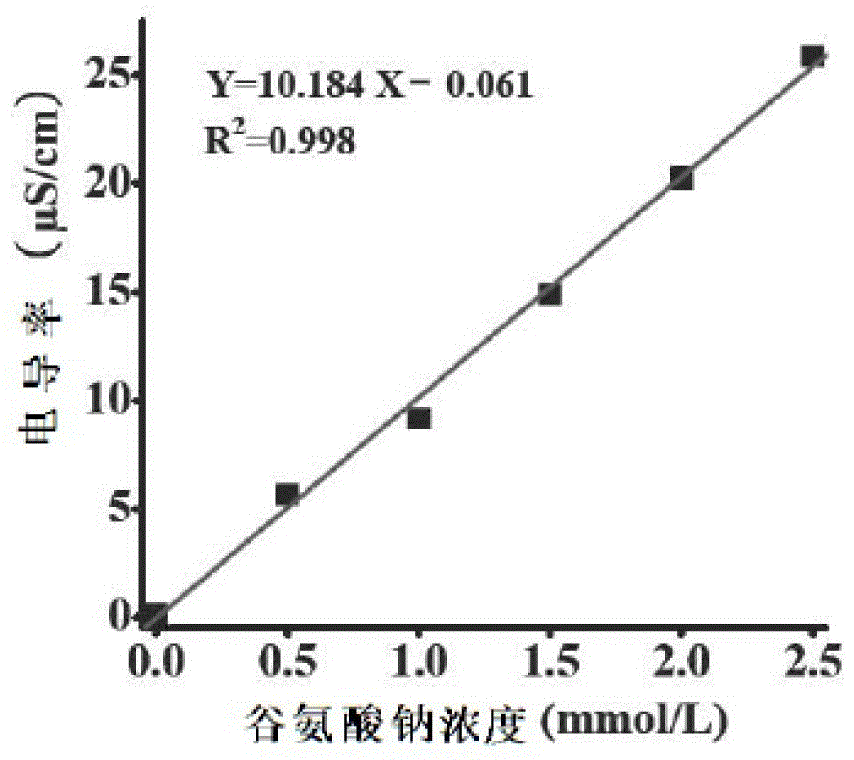

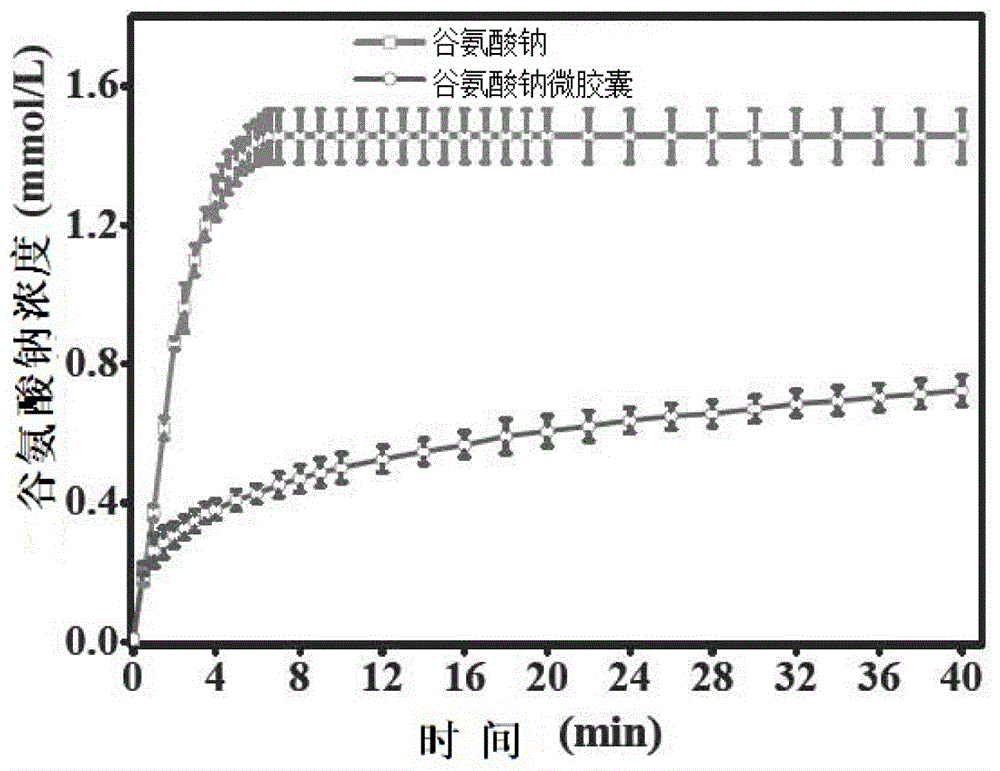

[0024] 2. Detection o...

Embodiment 2

[0032] Take by weight 1 part of 5'-disodium guanylate, 1 part of chitosan and 1 part of monolactic acid diglyceride, add 100 parts of ultrapure water, and prepare the flavor enhancer according to the method in Example 1 Microcapsules, but freeze-drying is used for final shaping. The prepared microcapsules were added to the processing of potato chips in an amount of 0.5% by weight of raw materials, and the processed finished products were tested. The results showed that the inhibition rates to acrylamide and 5-hydroxymethylfurfural were respectively 32.4% vs. 86.1%.

Embodiment 3

[0034] Weigh 3 parts of disodium succinate, 6 parts of beeswax and 3 parts of polyglycerol monostearate in parts by weight, add 300 parts of ultrapure water, and prepare flavor enhancer microcapsules according to the method in Example 1. The prepared microcapsules were added to the processing and production of bread according to the addition amount of 0.8% of the raw material weight, and the processed finished products were tested. The results showed that the inhibition rates of acrylamide and 5-hydroxymethylfurfural were 36.7 % and 87.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com