Electric actuator with pre-heating

A pre-charging, electric vehicle technology, applied in the field of vehicles, can solve problems such as damage to electronic amplifiers, high cost, inability to provide turn-on current, etc., and achieve the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

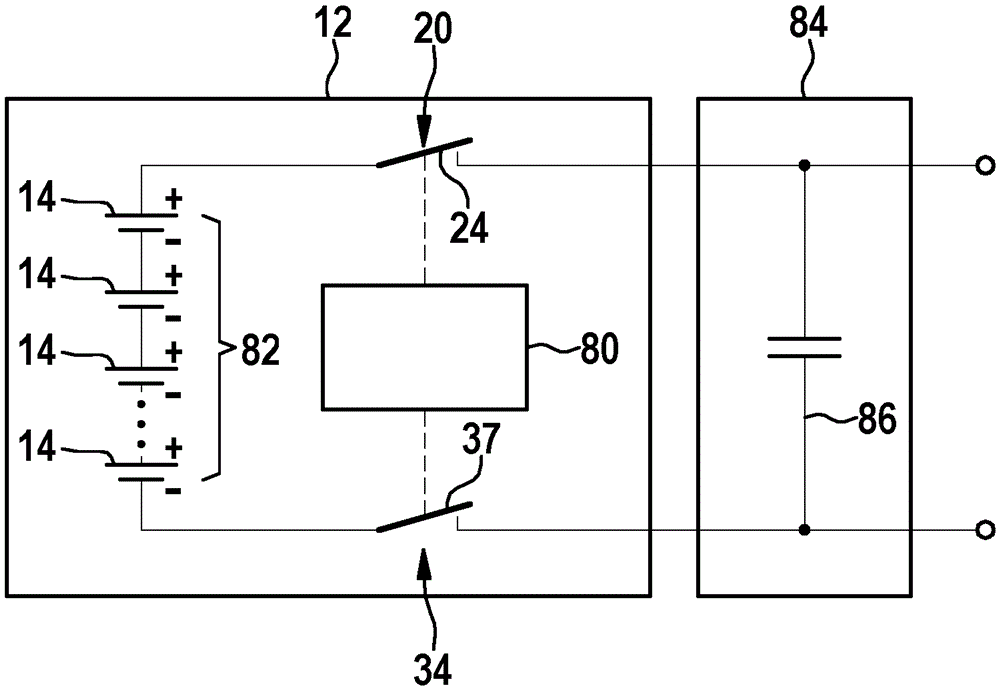

[0030] from according to figure 1 A schematic circuit diagram of an electrical energy store with a battery separation unit is known from the illustration in .

[0031] exist figure 1 The battery separation unit 10 shown in is connected to a high-voltage battery 12 . The high-voltage battery includes a battery pack or a battery module, inside which a plurality of battery cells 14 are electrically connected to each other. According to figure 1 In the illustration in , the high-voltage battery 12 also includes a service plug 16 .

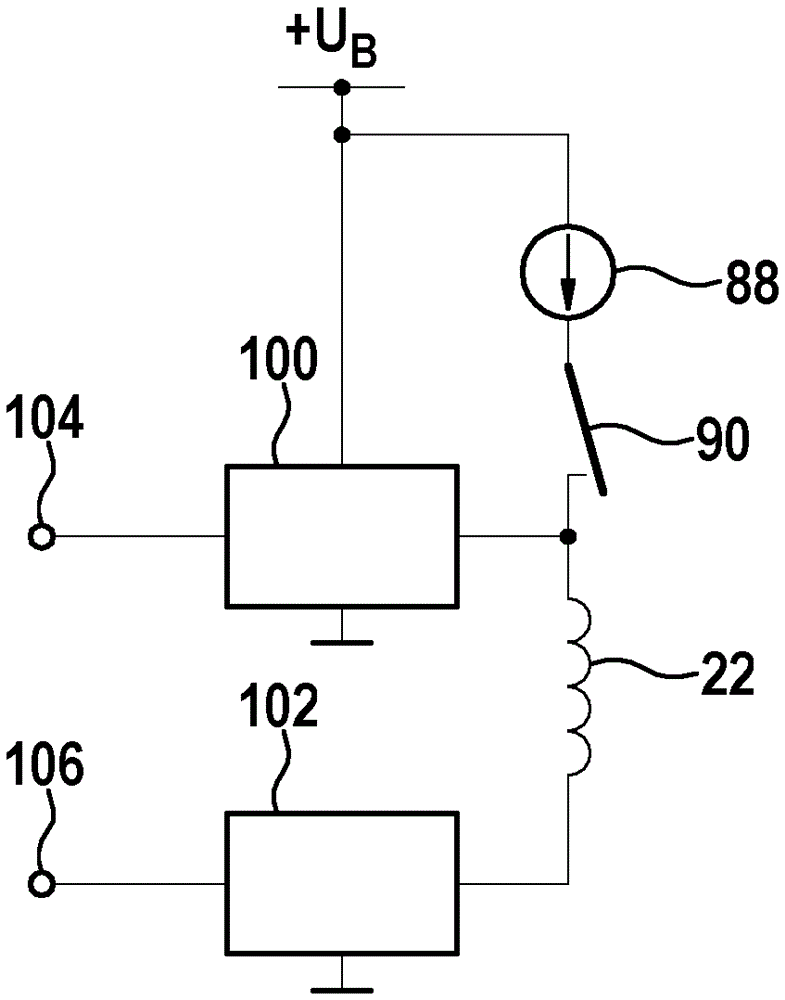

[0032] A battery separation unit 10 designated with reference numeral 10 comprises a positive battery pole 18 and a negative battery pole 32 . The battery disconnecting unit 10 contains a main contactor 20 for the positive battery pole 18 in a first battery connection line 42 . Main contactor 20 includes an electromechanical switch 24 , which is also referred to as a main contactor switch for battery positive pole 18 and is actuated via a main con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com