Comprehensive functional membrane, manufacturing method thereof, and OLED display panel

A production method and technology of functional film, applied in semiconductor/solid-state device manufacturing, instrumentation, electrical digital data processing, etc., can solve problems such as complicated process flow and low yield rate, achieve simplified process flow, ensure product yield rate, reduce The effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

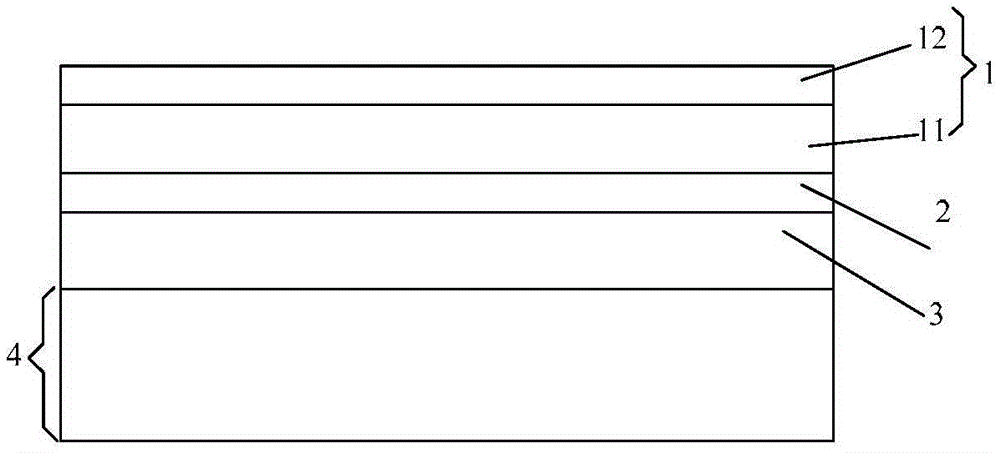

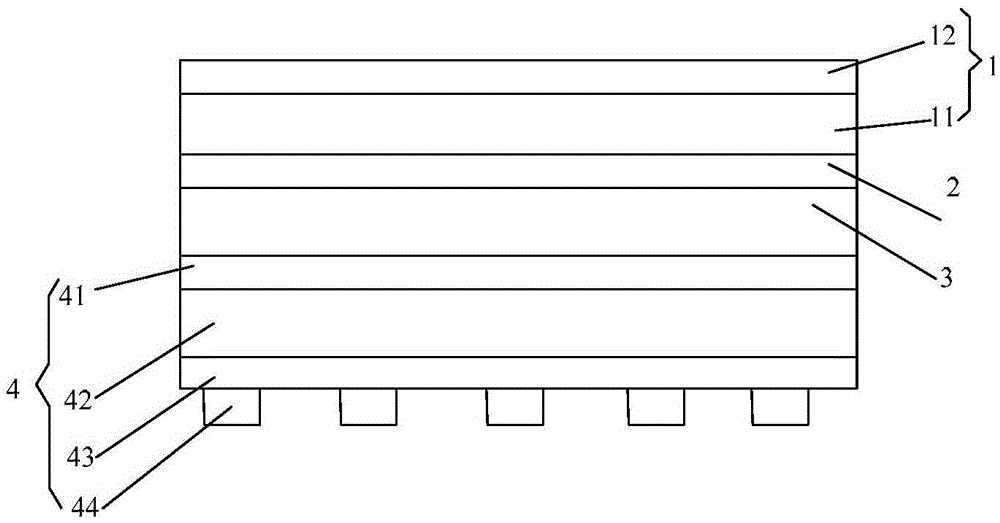

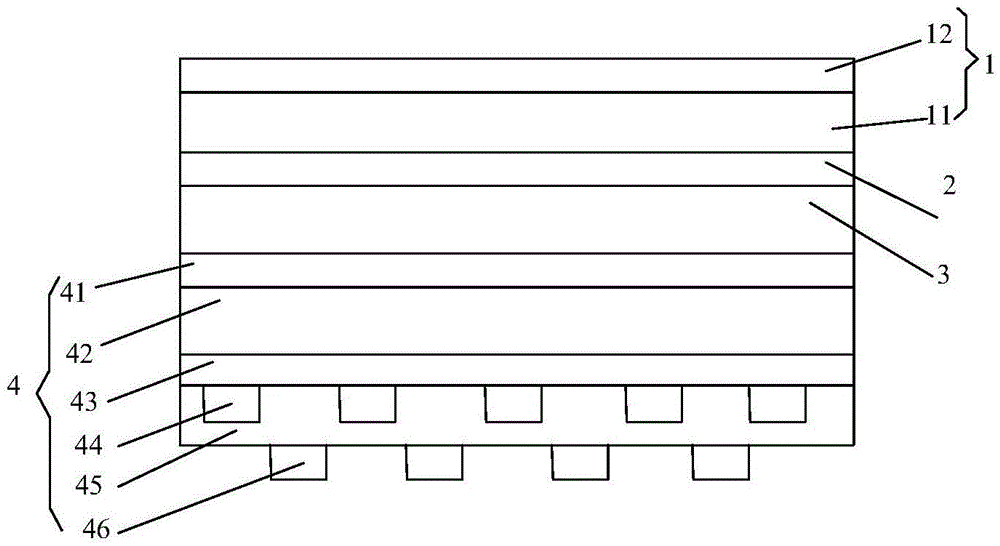

[0035] As described in the background technology, the existing circular polarizer, water-oxygen barrier layer, touch layer and protective cover are arranged separately, and need to be bonded layer by layer when making OLED display panels, resulting in complicated processes and low yields. To solve the above problems, in a typical embodiment of the present application, a comprehensive functional film is provided, such as figure 1 As shown, the comprehensive functional film includes a linear polarizer 1, a 1 / 4 wave plate 3 and a touch film group 4 with a barrier function. A hardened protective layer 12 on one side surface, the pencil hardness of the hardened protective layer 12 is above 5H; 1 / 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com