Hardware testing equipment of battery management system

A battery management system and hardware testing technology, applied in electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of large error and low testing efficiency of battery management system, so as to improve accuracy, improve testing efficiency and accurate testing results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

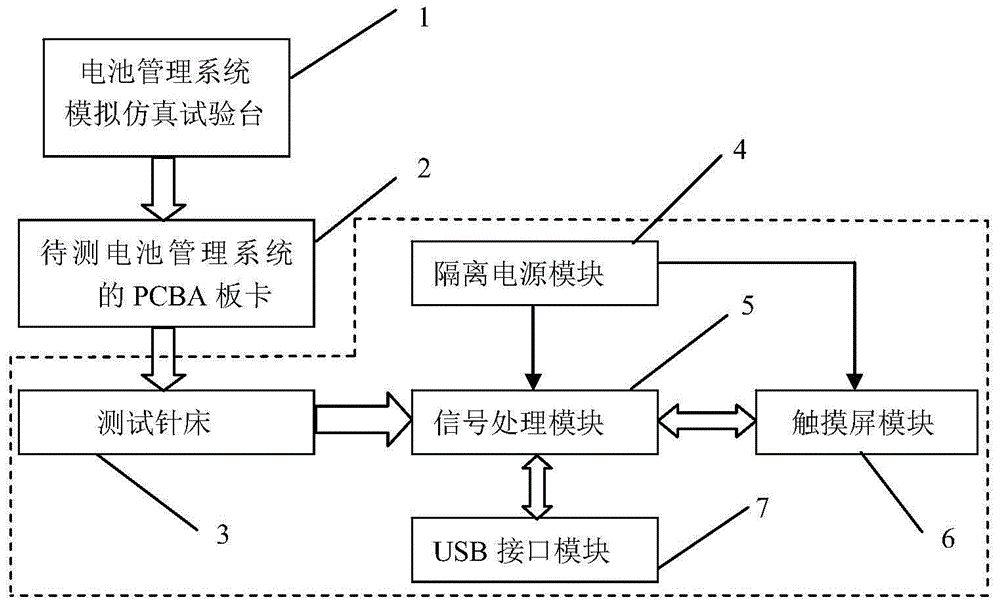

[0012] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. A battery management system hardware testing device described in this embodiment includes a test bed of needles 3, an isolated power supply module 4, a signal processing module 5, a touch screen module 6, and a USB interface module 7;

[0013] The isolated power supply module 4 provides a power supply isolated from the PCBA board 2 of the battery management system to be tested for the signal processing module 5 and the touch screen module 6,

[0014] The PCBA board 2 of the battery management system to be tested is fixed on the test needle bed 3, the test points on the PCBA board 2 of the battery management system to be tested are in close contact with the probes of the test needle bed 3, and the signal acquisition of the test needle bed 3 The wiring harness is connected to the test signal input end of the signal processing module 5, the input / output end one of the signal processing ...

specific Embodiment approach 2

[0015] Specific implementation mode two: refer to figure 2 Describe this embodiment in detail. This embodiment is a further description of a battery management system hardware testing device described in Embodiment 1. In this embodiment, the signal processing module 5 includes an interface module 5-1, a level conversion module 5-2, signal isolator 1 5-3, signal conditioning module 5-4, multi-choice one analog switch 5-5, A / D converter 5-6, signal isolator 2 5-7 and DSP 5-8;

[0016] The input end of the interface module 5-1 is the input end of the signal processing module 5, the digital signal output end of the interface module 5-1 is connected to the input end of the level conversion module 5-2, and the DSP input circuit of the level conversion module 5-2 The flat signal output terminal is connected to the input terminal of the signal isolator-5-3, the output terminal of the signal isolator-5-3 is connected to the GPIO port of the DSP5-8, and the analog signal output termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com