Asphalt pavement aging simulating method

A simulation method, technology of asphalt pavement, applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

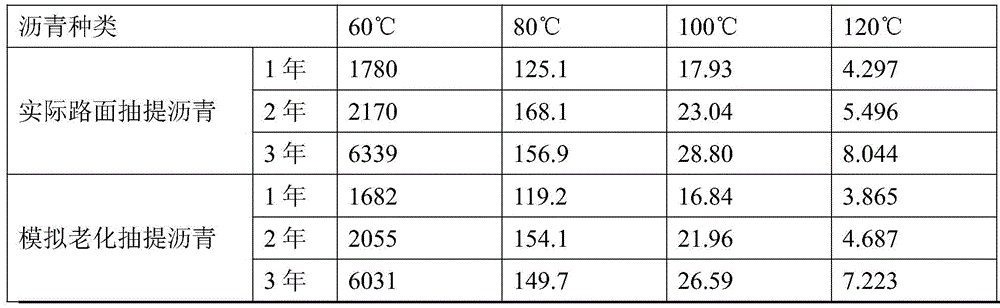

[0020] The asphalt pavement aging simulation is carried out by taking the pavement in service for one year in a certain area of Hubei as an example. The asphalt layer thickness A of this road section is 20 mm, the annual average temperature is 16.3 °C, and the total annual ultraviolet radiation D is 1.83×10 8 J / m 2 , the ultraviolet radiation intensity C of the multifunctional pavement material life analyzer is 73W / m 2 , the service life n is 1; the maximum rainfall E is 280.6mm, the spray rainfall F of the multifunctional pavement material life analyzer is 80mm / d; the lane coefficient G is 0.4, the wheel track distribution coefficient H is 56.8%, the temperature The coefficient I is 0.417, the daily average traffic volume J is 20998, and the average axle load conversion coefficient K is 0.1237.

[0021] 1) Aggregate, mineral powder and SBS modified asphalt (asphalt ratio of 5.2) were weighed according to the commonly used gradation, and asphalt mixture rutting specimens we...

Embodiment 2

[0026] The asphalt pavement aging simulation is carried out by taking the pavement that has been in service for 2 years in a certain area of Hubei as an example. The asphalt layer thickness A of this road section is 20mm, the annual average temperature is 16.3°C, and the total annual ultraviolet radiation D is 1.83×10 8 J / m 2 , the ultraviolet radiation intensity C of the multifunctional pavement material life analyzer is 73W / m 2 , the service life n is 2; the maximum rainfall E is 280.6mm, the spray rainfall F of the multifunctional pavement material life analyzer is 80mm / d; the lane coefficient G is 0.4, the wheel track distribution coefficient H is 56.8%, the temperature The coefficient I is 0.417, the daily average traffic volume J is 20998, and the average axle load conversion coefficient K is 0.1237.

[0027] 1) Aggregate, mineral powder and SBS modified asphalt (asphalt ratio of 5.2) were weighed according to the commonly used gradation, and asphalt mixture rutting s...

Embodiment 3

[0032] The asphalt pavement aging simulation is carried out by taking the pavement that has been in service for 3 years in a certain area of Hubei as an example. The asphalt layer thickness A of this road section is 20mm, the annual average temperature is 16.3°C, and the total annual ultraviolet radiation D is 1.83×10 8 J / m 2 , the ultraviolet radiation intensity C of the multifunctional pavement material life analyzer is 73W / m 2 , the service life n is 3; the maximum rainfall E is 280.6mm, the spray rainfall F of the multi-functional pavement material life analyzer is 80mm / d; the lane coefficient G is 0.4, the wheel track distribution coefficient H is 56.8%, the temperature The coefficient I is 0.417, the daily average traffic volume J is 20998, and the average axle load conversion coefficient K is 0.1237.

[0033] 1) Aggregate, mineral powder and SBS modified asphalt (asphalt ratio of 5.2) were weighed according to the commonly used gradation, and asphalt mixture rutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com