An automatic control detection device and detection method for cigarette burning cone drop performance

A technology of detection device and combustion cone, which is applied in measurement device, radiation pyrometry, and testing material strength by applying repetitive force/pulse force, etc. problems, etc., to achieve the effect of mature control methods, cost reduction, intelligence and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

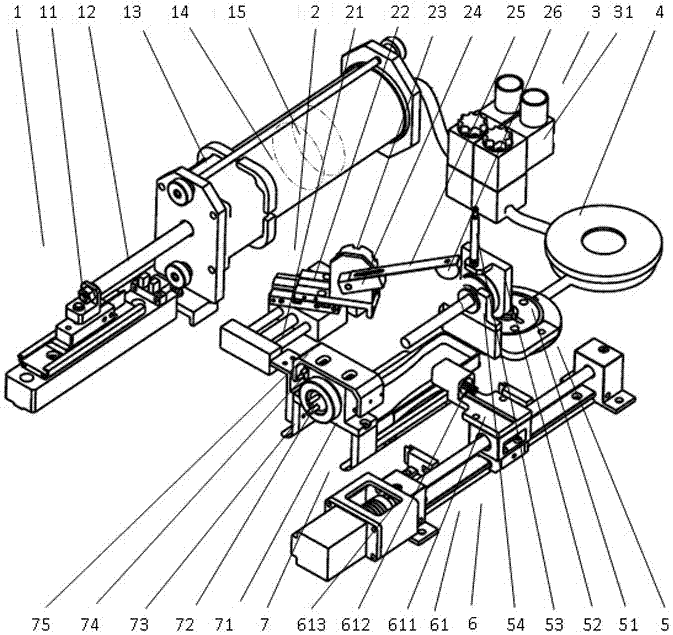

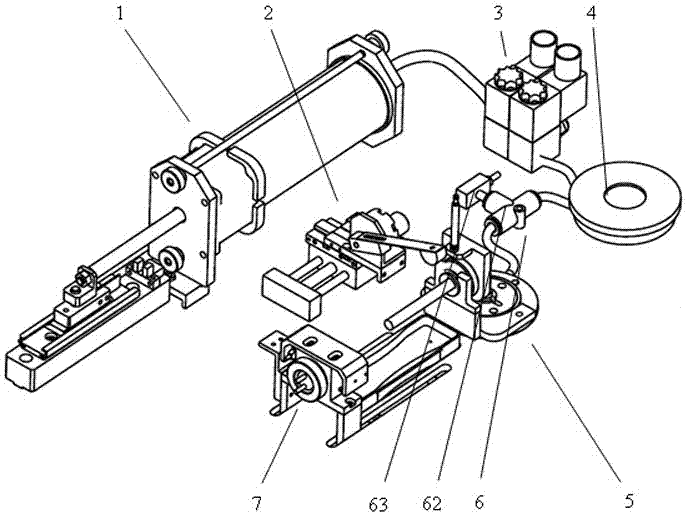

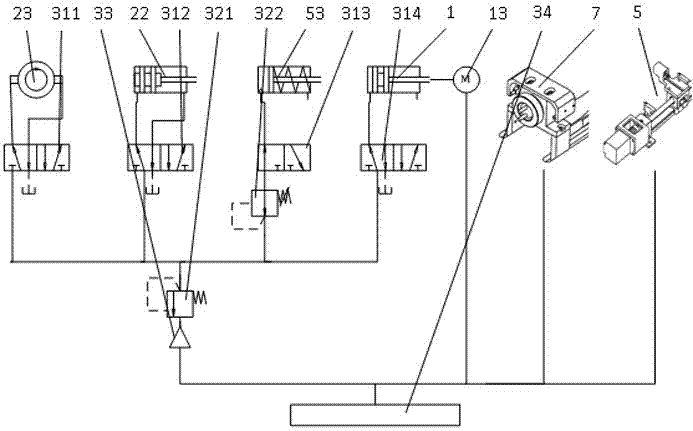

[0047] Below in conjunction with accompanying drawing, structure and test method of the present invention are further described:

[0048] Such as Figure 1-3 Shown: an automatic control and detection device for cigarette burning cone head drop performance, including a suction unit 1, a cigarette flick unit 2, a cigarette clamping unit 5, a head drop detection unit 6, a cigarette lighting unit 7 and a device for controlling the above-mentioned The five-unit circuit gas circuit control unit 3 communicates between the suction unit 1 and the cigarette holding unit 5 sequentially through the solenoid valve group 31, the filter assembly 4 and corresponding pipelines, and the cigarette lighting unit 7 is located in the cigarette holding unit. Right in front of the unit 5, the cigarette flicking unit 2 is located on the side of the cigarette clamping unit 5; the head drop detection unit 6 uses the infrared temperature measurement head drop detection mechanism 61 or the micro pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com