Anti-warping device

An anti-warping and anti-warping technology, used in measuring devices, instruments, scientific instruments, etc., can solve problems such as failure of test data, and achieve the effects of simple device structure, good practical application value, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by specific embodiment this patent is described in further detail:

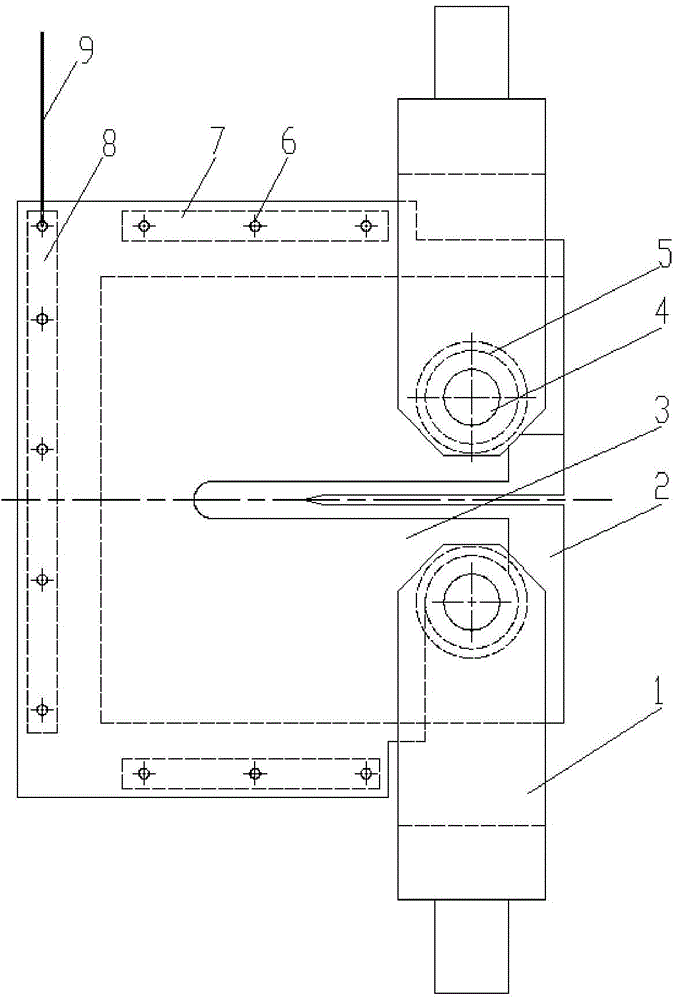

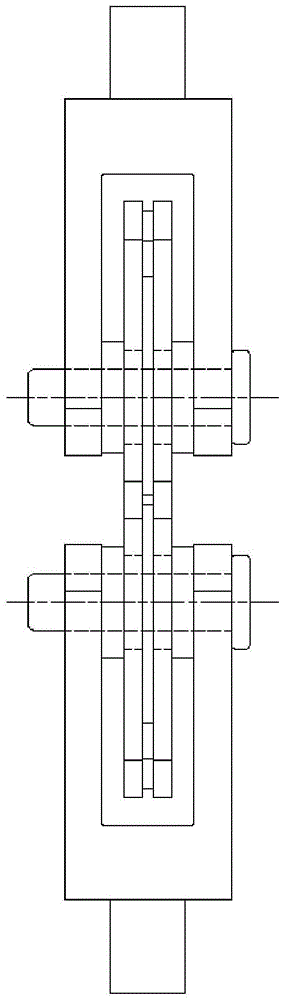

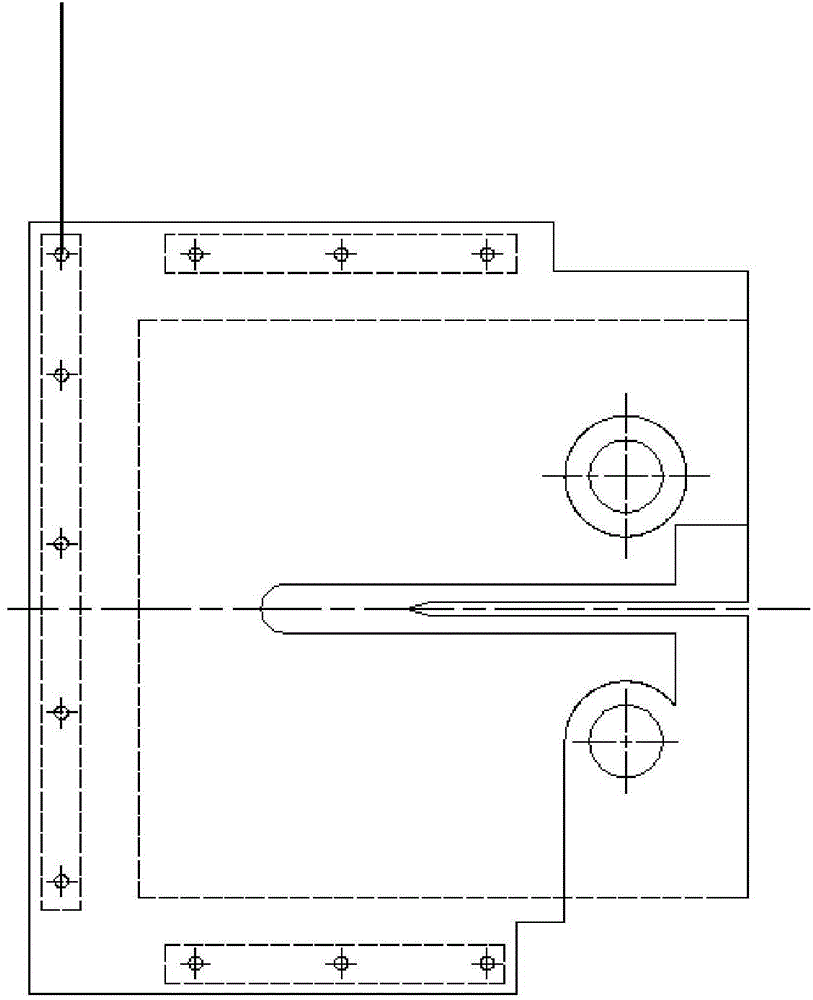

[0026] See Figure 1 and figure 2 , which are the loading structure diagram of the K-R curve test of the thin plate measured by the compact tensile sample of the patented device, and the assembly diagram of the patented device and the sample. The patented device comprises a rectangular anti-sway plate 3, a step washer 5, a connecting bolt 6, a horizontal backing plate 7, a vertical backing plate 8 and a device buckle rope 9. The characteristics of each part of the device are as follows:

[0027] The rectangular anti-sway plate 3 is the main component of this patent, and there are two pieces in total, and the structural form is shown in Figure 4. The rectangular anti-warping plate 3 is two flat plates with the same shape machined from the steel plate, the thickness is about 5 times the thickness of the sample, and the surface is smooth and flat. The upper connection hole and the lower positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com