Coil series cyclone wet dust removal coal-fired boiler

A technology for wet dust removal and coal-fired boilers, applied in the directions of combustion technology mitigation, greenhouse gas reduction, climate sustainability, etc., can solve problems such as difficulty in disassembly, and achieve the improvement of disassembly and assembly technology, elimination of tension, and enhancement of axial direction. elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with accompanying drawing, the present invention is described in further detail.

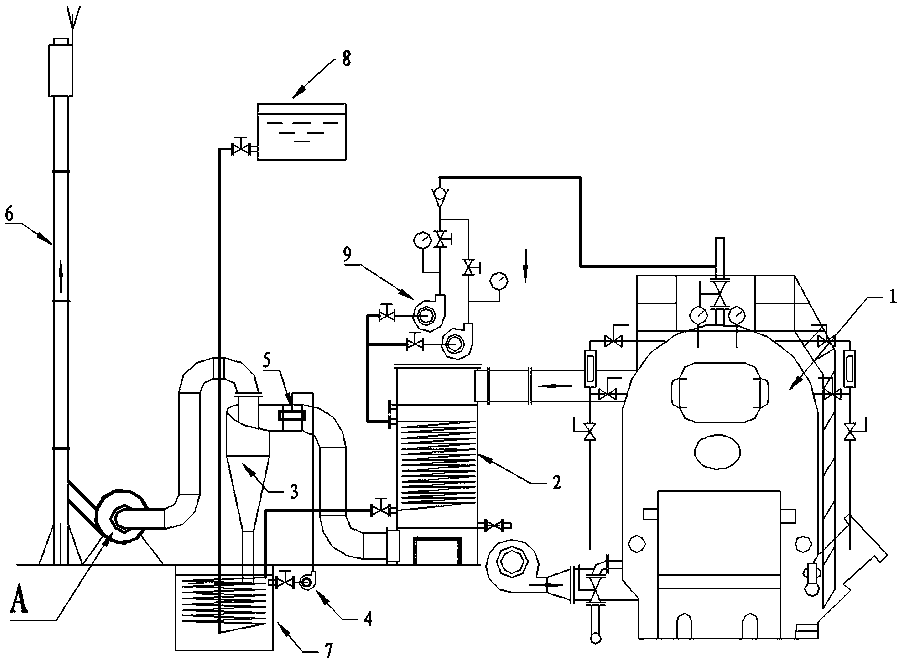

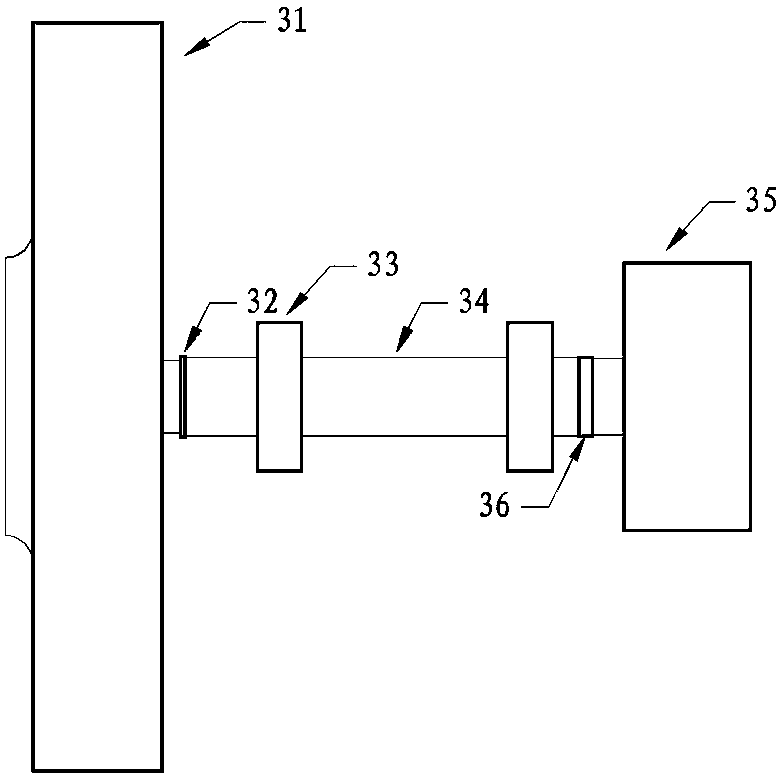

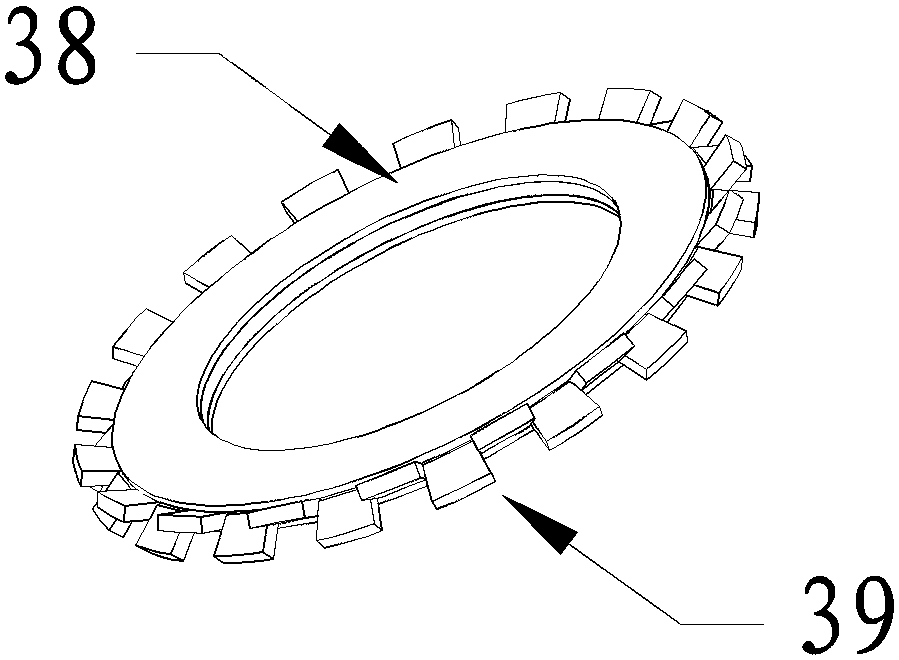

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The coil series-type cyclone wet-process dedusting coal-fired boiler shown includes the boiler main body 1, and the high-temperature tail gas pipe of the boiler main body is connected to the induced draft fan A through the water preheating coil heat exchanger 2 and the cyclone dust collector 3; the bottom of the cyclone dust collector 3 Connect to the sewage pool 7, the water in the sewage pool 7 is connected to the spray plate 5 in the cyclone dust collector 3 through the spray pump 4; After the two-stage preheating of the device, water is supplied to the boiler through the high-pressure pump system; the induced draft fan A includes a fan impeller 31, a bearing 33, a fan shaft 34 and a pulley 35, and the pulley 35 and the fan shaft 34 and the fan impeller 31 and the fan shaft 34 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com