Technique and method for achieving power generation by means of explosion of extremely-low-concentration gas

A gas explosion and concentration technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as no application value, unsuitable gas, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

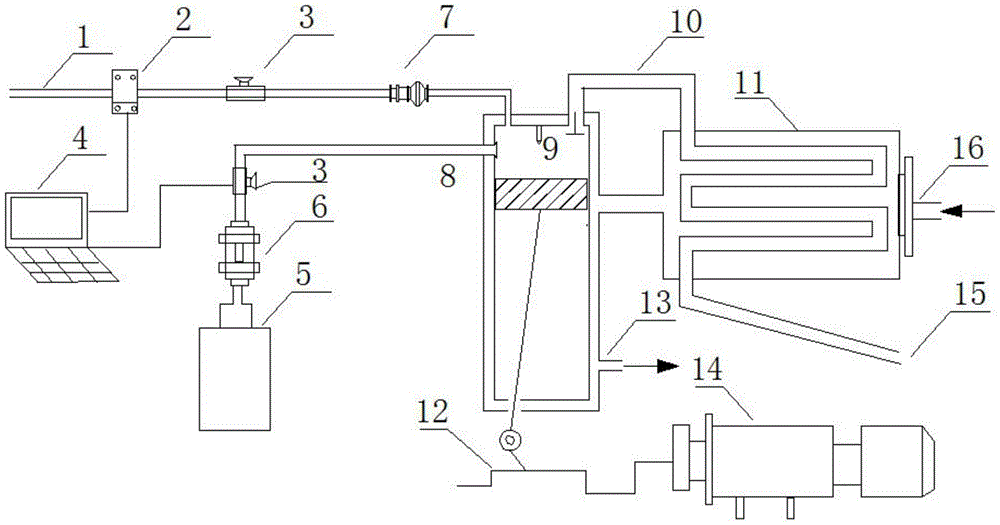

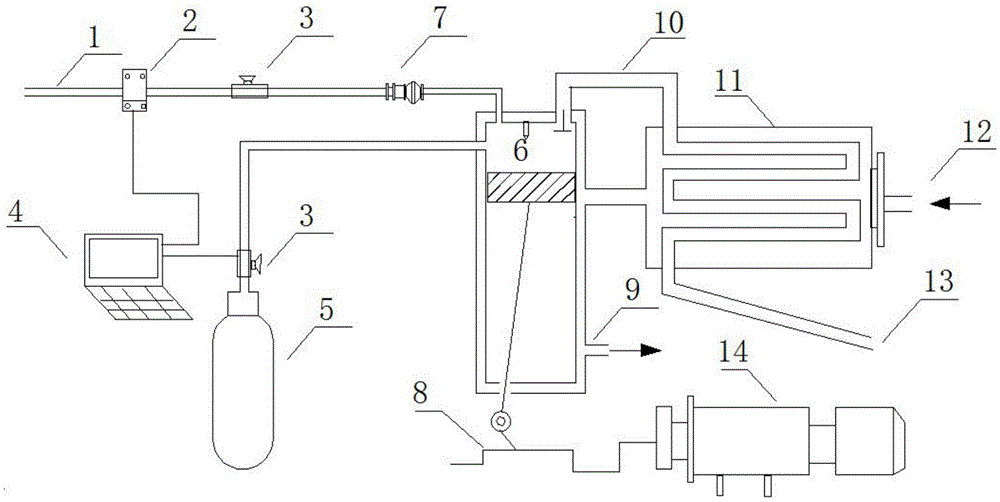

[0024] According to the above-mentioned technology and method of using extremely low-concentration gas explosion to generate electricity, it includes a gas transportation and drying system, a liquid atomization system, a gas distribution system, a cooling system, a waste heat utilization system, a heat engine system, and a power generation system. A certain pressure and concentration of gas-air mixed gas is introduced from the gas conveying and drying system, and at the same time, according to the concentration of the injected gas, a certain concentration of combustible liquid is atomized or combustible gas is sprayed into the cylinder to ignite to make the mixture explode and push the cylinder to do work. The power generation system thus converts mechanical energy into electrical energy. The cylinder has a cooling system, and the high-temperature exhaust gas generated by the explosion is recovered through the waste heat utilization system, thereby improving the comprehensive u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com