Method for exploiting heavy oil reservoir through steam-assisted gravity drainage (SAGD)

A technology for heavy oil reservoirs and reservoirs, applied in the field of heavy oil reservoirs exploited by SAGD, can solve problems such as uneven development of medium and steam chambers, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The main oil layer of the heavy oil reservoir in this example is buried shallowly, with an average buried depth of 300m, the original reservoir pressure of 2.8MPa, and the original reservoir temperature of 21°C; the viscosity of crude oil is high, and the viscosity of degassed crude oil at the reservoir temperature is 22× 10 4 mPa.s, the average effective thickness of the oil layer is 16m.

[0047] The mining method of the present embodiment comprises the following specific steps:

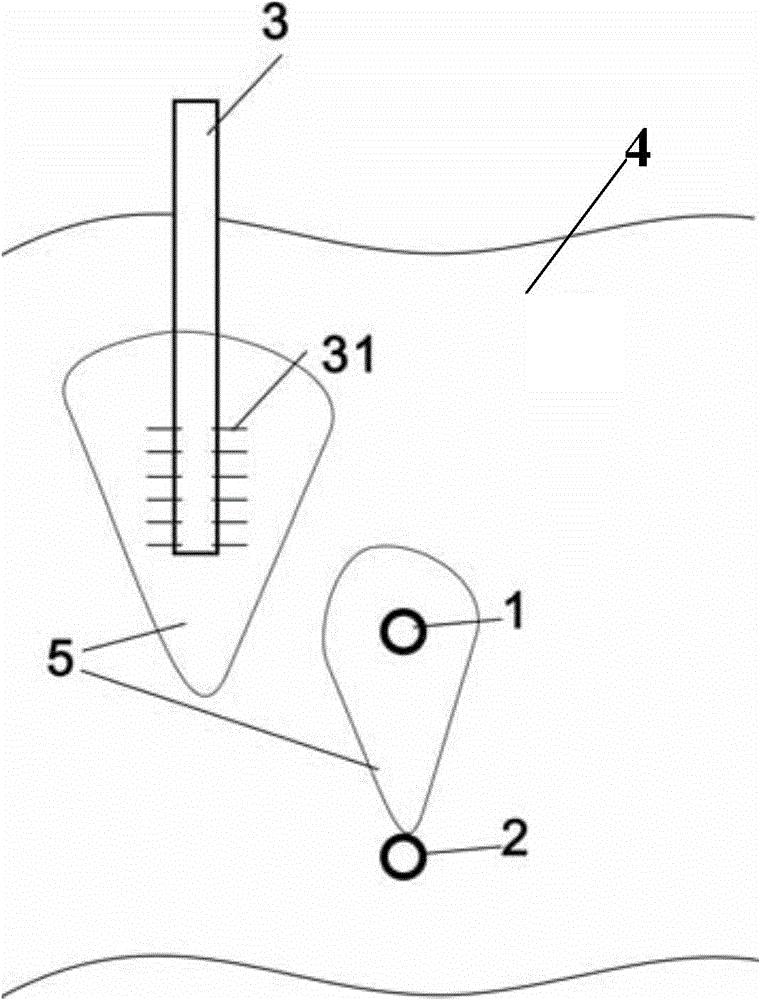

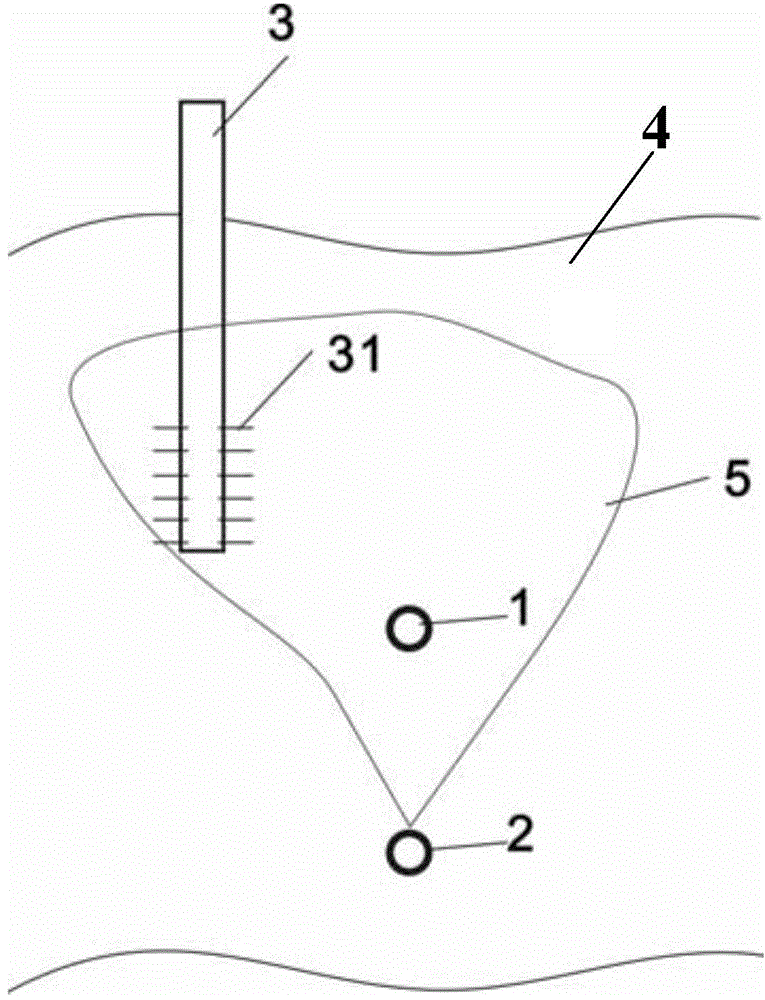

[0048] (1) Set up a horizontal injection-production well pattern in the production area of the heavy oil reservoir, and set up a well pattern in the oil layer at the same plane position (the plane position refers to the vertical plane position, and the horizontal section of the injection well is located directly above the horizontal section of the production well). For injection well 1 and production well 2, the injection well 1 and production well 2 form an injection-production well grou...

Embodiment 2

[0055] The main oil layer of the heavy oil reservoir in this example is buried shallowly, with an average buried depth of 300m, the original reservoir pressure of 2.8MPa, and the original reservoir temperature of 21°C; the viscosity of crude oil is high, and the viscosity of degassed crude oil at the reservoir temperature is 22× 10 4 mPa.s, the average effective thickness of the oil layer is 16m.

[0056] The mining method of the present embodiment comprises the following specific steps:

[0057] (1) Set up a horizontal injection-production well pattern in the production area of the heavy oil reservoir, and set up a well pattern in the oil layer at the same plane position (the plane position refers to the vertical plane position, and the horizontal section of the injection well is located directly above the horizontal section of the production well). For injection well 1 and production well 2, the injection well 1 and production well 2 form an injection-production well grou...

Embodiment 3

[0064] The main oil layer of the heavy oil reservoir in this example is buried shallowly, with an average buried depth of 300m, the original reservoir pressure of 2.8MPa, and the original reservoir temperature of 21°C; the viscosity of crude oil is high, and the viscosity of degassed crude oil at the reservoir temperature is 22× 10 4 mPa.s, the average effective thickness of the oil layer is 16m.

[0065] The mining method of the present embodiment comprises the following specific steps:

[0066] (1) Set up a horizontal injection-production well pattern in the production area of the heavy oil reservoir, and set up a well pattern in the oil layer at the same plane position (the plane position refers to the vertical plane position, and the horizontal section of the injection well is located directly above the horizontal section of the production well). For injection well 1 and production well 2, the injection well 1 and production well 2 form an injection-production well grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com