Combined cutting PDC (polycrystalline diamond compact) bit provided with breaking hammer

A composite cutting and breaking hammer technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of difficult rock cutting, fast wear and low rock breaking rate of the drill bit, and achieve the effect of improving the drilling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

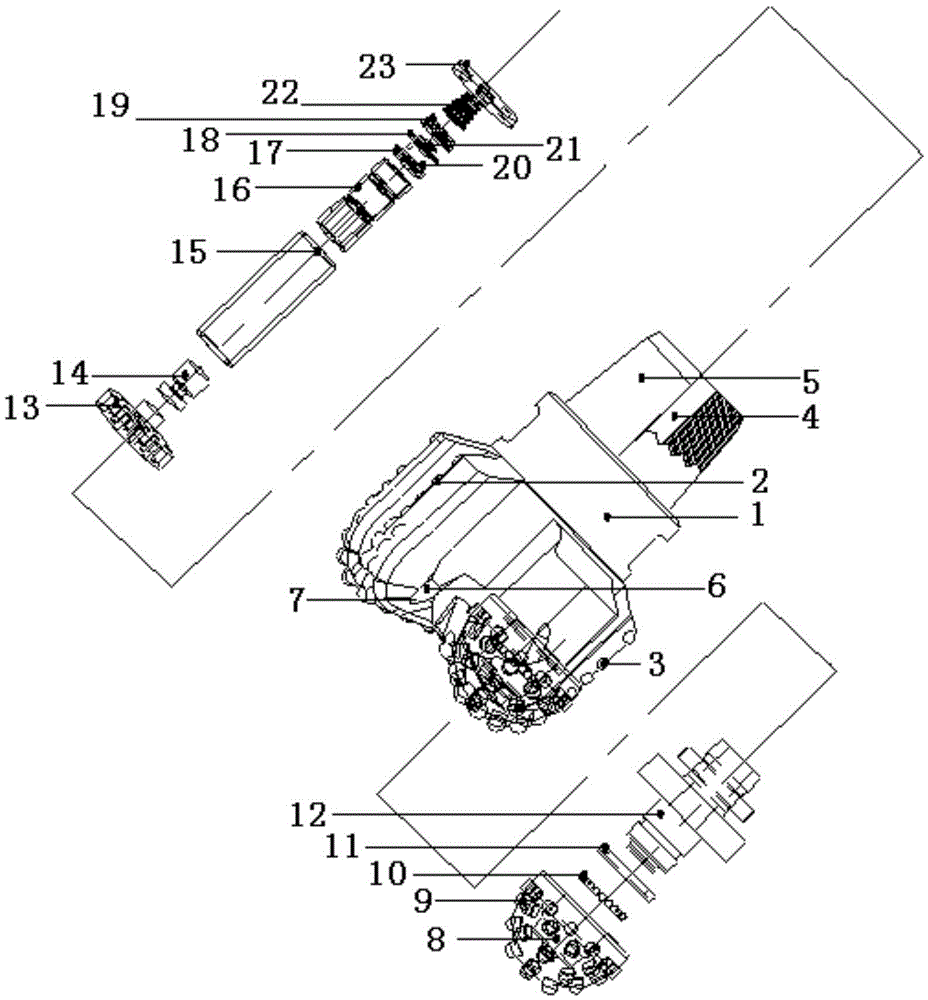

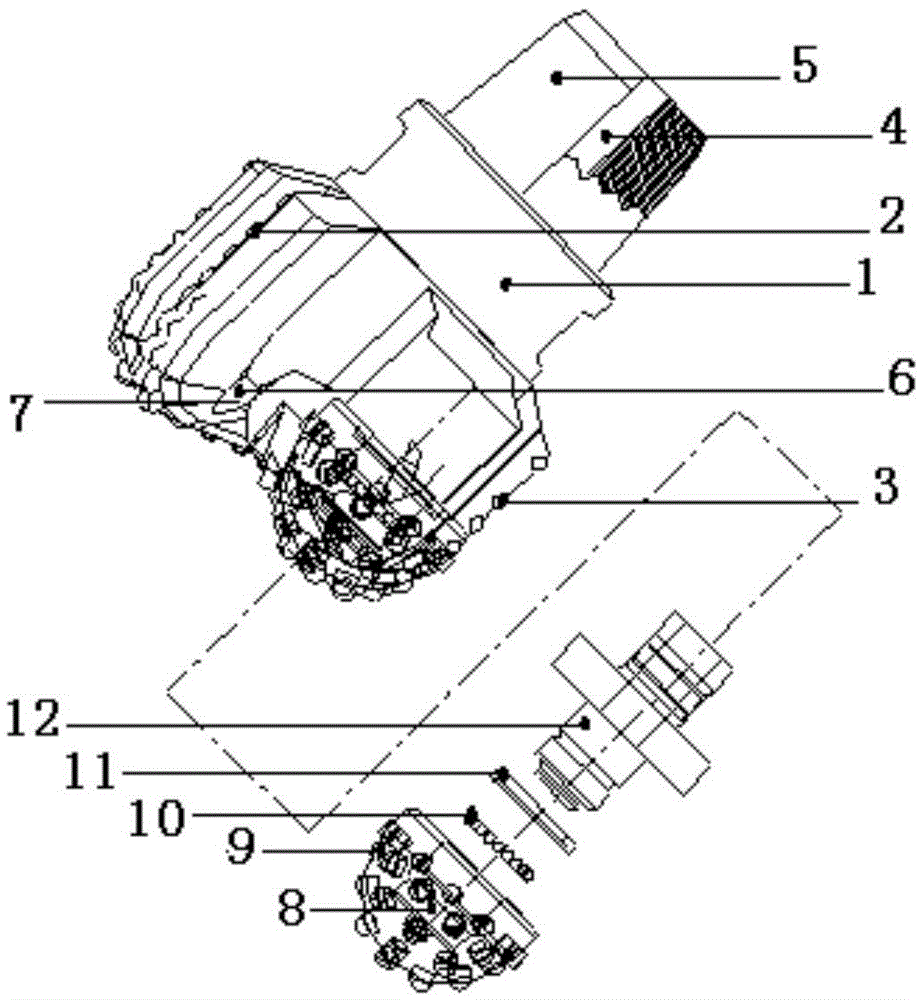

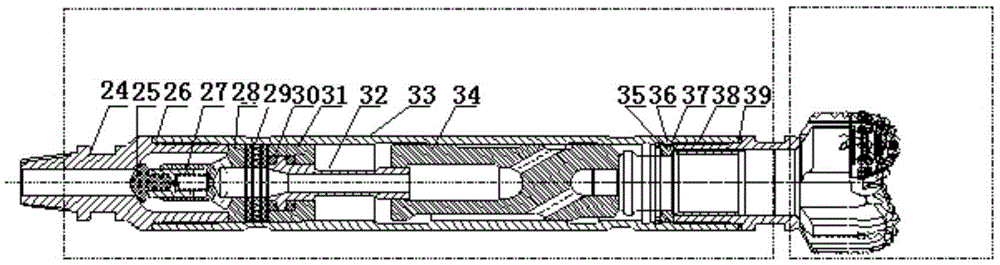

[0028] see figure 1 , shows an exploded schematic view of one embodiment of the breaker compound cutting PDC drill bit of the present invention.

[0029] The breaker compound cutting PDC drill bit at least includes a drill body 1 and a breaker 8, and in this embodiment may also include an impact generator, so that the whole drill bit is composed of three parts.

[0030] Wherein, the drill bit body 1 is provided with a plurality of drill bit blades 2, and a plurality of PDC cutting teeth 3 for cutting rocks are arranged on the drill bit blade 2, and the drill bit body 1 is provided with an inner flow channel 4, and the drill bit body 1 A plurality of cleaning holes 6 are provided between the drill blade blades 2, and the front end of the inner flow channel 4 communicates with the cleaning holes 6, and the cleaning holes 6 are arranged to protect the drill body 1 from being damaged by erosion and can be adjusted. The movable nozzle 7 with the flow rate is sealed and installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com