Paving method for tropical zone road surface

A laying method and regional technology, applied to roads, roads, on-site paved coagulation pavements, etc., can solve problems such as cracking, damage, and cost increase, and overcome low strength, easy deformation, stability and strength Improvement, the effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

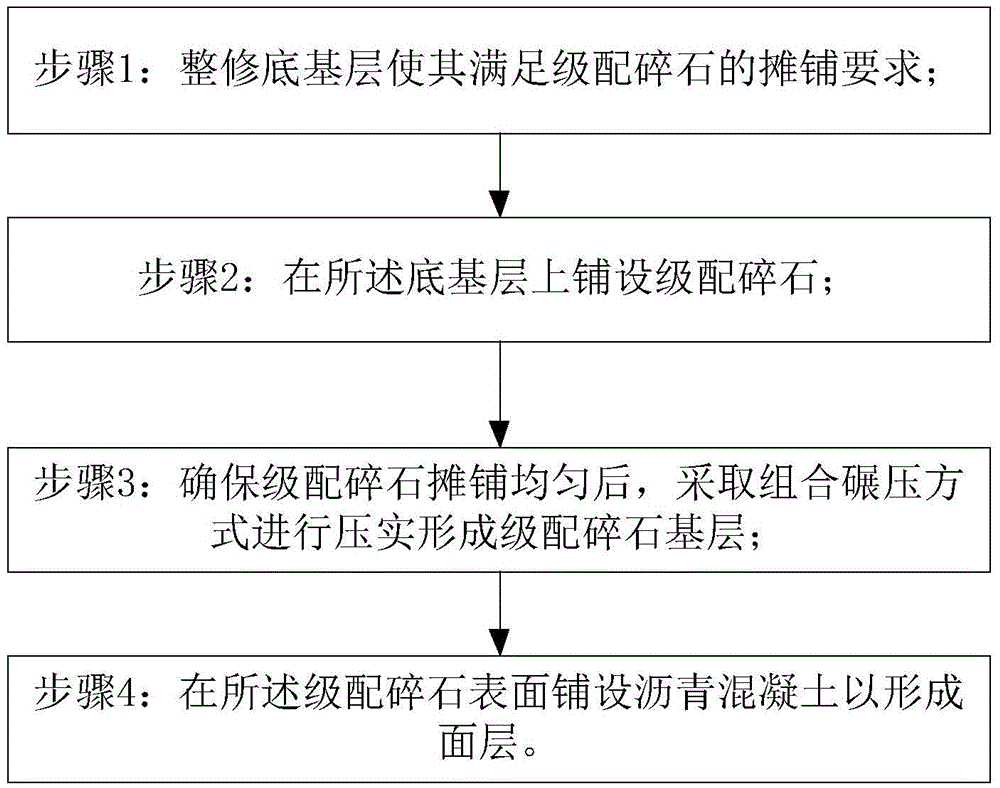

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0029] The present invention provides a pavement laying method in tropical areas. It should be noted that before laying, the roadbed needs to be well planned to ensure that the roadbed of each road surface construction section has at least one rainy season settlement before construction. Specifically, we can make full use of the opportunity when the quality of the subgrade rebounds when the dry and wet seasons alternate in tropical areas. At the end of each rainy season and the beginning of the dry seaso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com