Preparing method for gradient distribution porous heat-insulation high-strength film functional coring soft bag used for lunar exploration soil sampling

A core-taking soft bag, gradient distribution technology, applied in bags, sacks, non-woven fabrics, etc., can solve the problems of soft bag accidental breakage, fiber performance degradation, etc., achieve good thermal protection, meet functional requirements, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

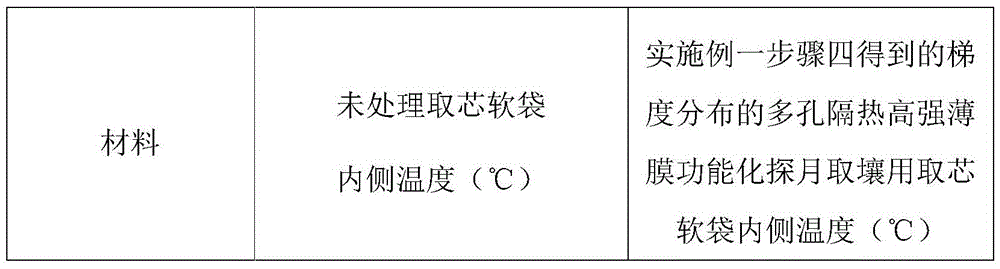

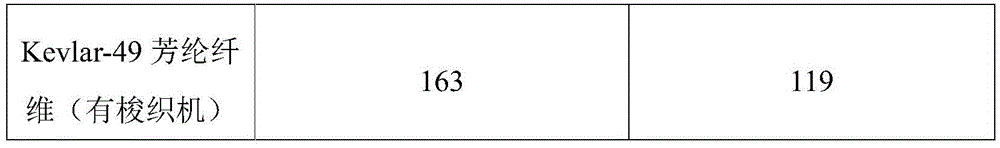

[0035] Specific implementation mode 1: This implementation mode is a kind of porous heat-insulating high-strength film with gradient distribution. The preparation method of the core soft bag for lunar exploration and soil collection is completed according to the following steps:

[0036] 1. Warp 80 to 300 fiber warp yarns, then weave tubular flexible fabrics with plain weave on the loom, and then neatly cut and edge them to obtain cores with a diameter of 16.5mm to 27mm and a length of 200mm to 2500mm soft bag;

[0037] The fiber warp yarn described in step 1 is one of the Kevlar fibers of 50 denier to 1600 denier or a mixture of several of them;

[0038] The loom described in step 1 is a shuttle loom, a shuttleless loom or a circular loom;

[0039] 2. Prepare different concentrations of Kevlar nanofiber solutions:

[0040] ①. Prepare a dark red Kevlar nanofiber solution with a mass fraction of 0.3%;

[0041] Use nitrogen to purge the dry three-necked flask for 20min to 30m...

specific Embodiment approach 2

[0065] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, 168 fiber warp yarns are warped, and then the tubular flexible fabric is weaved by plain weave on a loom, and then neatly cut and edged, to obtain A soft core bag with a diameter of 20.5mm and a length of 200mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0066]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the warp yarn of the fiber described in step 1 is Kevlar-29 aramid fiber of 130 denier. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com