A self-repairing material and concrete with the self-repairing material and its preparation

A self-repairing material, concrete technology, applied in the field of building materials, can solve the problems of poor stability of concrete matrix, poor controllability, and insignificant recovery of mechanical properties, so as to improve long-term effectiveness and controllability, improve mechanical properties, and dissolve The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

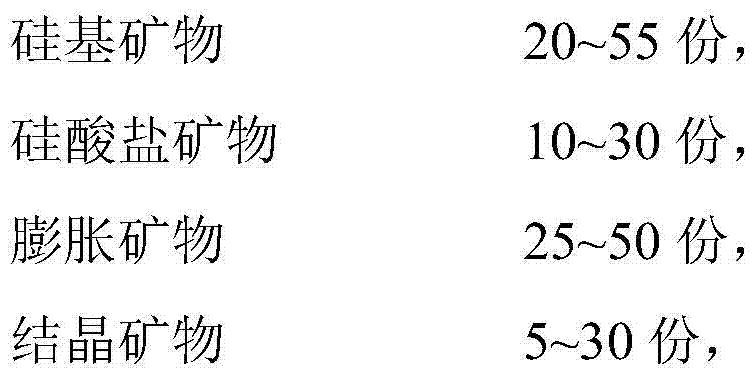

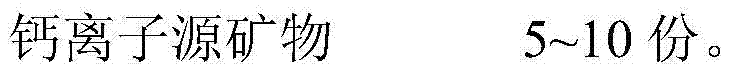

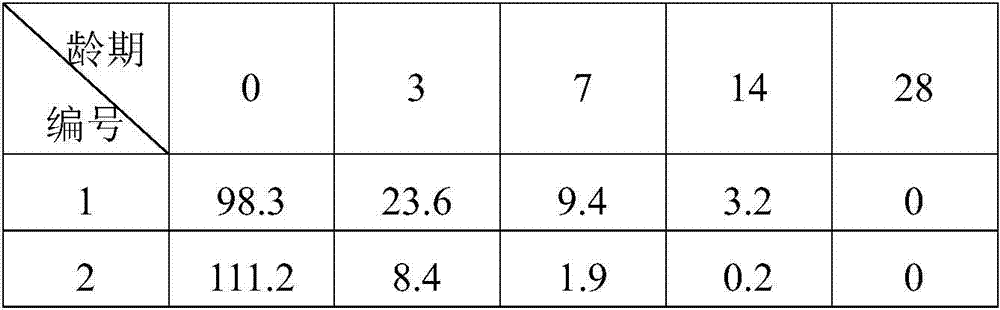

[0042] A self-dissolving hybrid mineral self-repairing material, the self-repairing material is composed of uniformly mixed mineral component microspheres, and the mineral component microspheres are composed of mineral components and a carrier protective film coated with mineral components , The self-healing material contains the following mineral components in parts by weight: 20 parts of silicon-based minerals, 10 parts of silicate minerals, 25 parts of expanded minerals, 5 parts of crystalline minerals, and 5 parts of calcium ion source minerals. Silicon-based minerals are compounded by silica fume and fly ash. Among the silicon-based minerals, the content of silicon oxide is 65wt%, the content of aluminum oxide is 10wt%, the content of calcium oxide is 18wt%, and the silicate mineral is sodium Bentonite-based bentonite has a layered structure, and its layers contain exchangeable cations, which have ion exchange capacity; the expanded mineral is composed of calcium aluminosi...

Embodiment 2

[0046] A self-dissolving hybrid mineral self-repairing material, the self-repairing material is composed of uniformly mixed mineral component microspheres, and the mineral component microspheres are composed of mineral components and a carrier protective film coated with mineral components , The self-healing material contains the following mineral components in parts by weight: 55 parts of silicon-based minerals, 30 parts of silicate minerals, 50 parts of expanded minerals, 30 parts of crystalline minerals, and 10 parts of calcium ion source minerals. Silicon-based minerals are compounded by silica fume and fly ash. In silicon-based minerals, the content of silicon oxide is 62wt%, the content of aluminum oxide is 12wt%, the content of calcium oxide is 15wt%, and the silicate mineral is calcium Bentonite-based bentonite has a layered structure, and its layers contain exchangeable cations, which have ion exchange capacity; the expanded mineral is composed of calcium aluminosilica...

Embodiment 3

[0050] A self-dissolving hybrid mineral self-repairing material, the self-repairing material is composed of uniformly mixed mineral component microspheres, and the mineral component microspheres are composed of mineral components and a carrier protective film coated with mineral components , The self-healing material contains the following mineral components in parts by weight: 40 parts of silicon-based minerals, 16 parts of silicate minerals, 30 parts of expanded minerals, 7 parts of crystalline minerals, and 7 parts of calcium ion source minerals. Silicon-based minerals are compounded by silica fume and fly ash. In silicon-based minerals, the content of silicon oxide is 65wt%, the content of aluminum oxide is 10wt%, and the content of calcium oxide is 18wt%. Desoiled, in a layered structure, the layers contain exchangeable cations, which have ion exchange capacity; the expanded mineral is composed of calcium aluminosilicate, alumina and calcium sulfate, and the chemical compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com