Waste slurry recycling and reusing technology of concrete mixing station

A mixing plant and concrete technology, which is applied in the field of waste slurry recycling and reuse technology in mixing plants, can solve the problems of increasing the operating cost of the mixing plant, waste of land resources, environmental pollution, etc., so as to solve the waste of land resources, save processing costs, and reduce production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

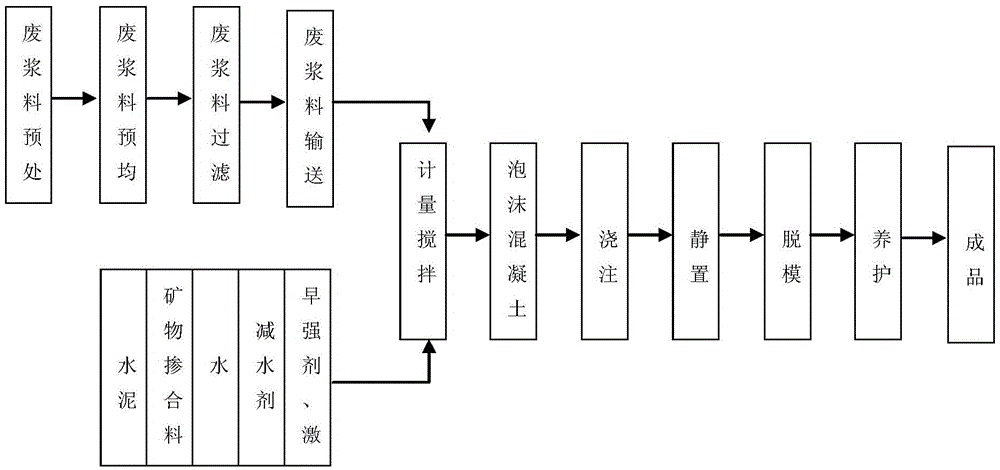

[0030] A process for recycling waste slurry from a concrete mixing station, the flow chart of which is shown in figure 1 , including the following steps:

[0031] 1) Pretreatment of waste slurry in the mixing station: In the waste slurry settling tank of the mixing station, a retarder (sodium gluconate) with a mass of 0.08% of the waste slurry is added, through the adsorption of the retarder and the generation of complexes, and Control the solid content of waste slurry to 50%;

[0032] 2) Pre-homogenization of waste slurry in the mixing station: transport the waste slurry treated with retarder from the sedimentation tank to the pre-homogenization tank, add water and stir for 3-5 minutes according to the ratio of water to slurry 1:1, and make a homogeneous waste slurry;

[0033] 3) Filtration and transportation of homogeneous waste slurry: transport the homogeneous waste slurry to the batching mixing tank through the slurry pump, wherein the head end of the slurry pump is prov...

Embodiment 2

[0037] A process for recycling waste slurry from a concrete mixing station, specifically comprising the following steps:

[0038] 1) Pretreatment of waste slurry in the mixing station: In the waste slurry settling tank of the mixing station, a retarder (sucrose) with a mass of 0.09% of the waste slurry is added to control the waste through the adsorption of the retarder and the generation of complexes. The solid content of the slurry is 50%;

[0039] 2) Pre-homogenization of waste slurry in the mixing station: transport the waste slurry treated with retarder from the sedimentation tank to the pre-homogenization tank, add water and stir for 3-5 minutes according to the ratio of water to slurry 1:1, and make a homogeneous waste slurry;

[0040] 3) Filtration and transportation of homogeneous waste slurry: transport the homogeneous waste slurry to the batching mixing tank through the slurry pump, wherein the head end of the slurry pump is provided with a filter screen with a mesh...

Embodiment 3

[0044] A process for recycling waste slurry from a concrete mixing station, specifically comprising the following steps:

[0045] 1) Pretreatment of waste slurry in the mixing station: In the waste slurry settling tank of the mixing station, a retarder (sucrose) with a mass of 0.09% of the waste slurry is added to control the waste through the adsorption of the retarder and the generation of complexes. The solid content of the slurry is 50%;

[0046] 2) Pre-homogenization of waste slurry in the mixing station: transport the waste slurry treated with retarder from the sedimentation tank to the pre-homogenization tank, add water and stir for 3-5 minutes according to the ratio of water to slurry 1:1, and make a homogeneous waste slurry;

[0047] 3) Filtration and transportation of homogeneous waste slurry: transport the homogeneous waste slurry to the batching mixing tank through the slurry pump, wherein the head end of the slurry pump is provided with a filter screen with a mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com